Tumbler Build - For cleaning plasma cut parts.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

13 Apr 2020 09:15 #163858

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Attachment not found

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

13 Apr 2020 09:29 #163859

by rodw

Replied by rodw on topic Tumbler Build - For cleaning plasma cut parts.

Looking good Stefan!

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

14 Apr 2020 13:13 #163947

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Attachment not found

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

15 Apr 2020 08:29 #164032

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Small Update.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

15 Apr 2020 08:30 - 15 Apr 2020 11:41 #164034

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Tom,

Do you have any tip on setting up my VFD?

Do you have any tip on setting up my VFD?

Last edit: 15 Apr 2020 11:41 by thefabricator03.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

15 Apr 2020 10:17 #164050

by rodw

Replied by rodw on topic Tumbler Build - For cleaning plasma cut parts.

I have a tip for you. Its called a VFD (Variable Frequency Drive)

Seriously though other than the fact I have one sitting here I have never used one. I have a mate who lives in my street who is a bit of an expert on them. But the wiring is simple but there is a bit in the programming. He typically uses the existing knob as a speed control but you can use an external one. Sing out if you need help, I might be able to enlist his help...

Seriously though other than the fact I have one sitting here I have never used one. I have a mate who lives in my street who is a bit of an expert on them. But the wiring is simple but there is a bit in the programming. He typically uses the existing knob as a speed control but you can use an external one. Sing out if you need help, I might be able to enlist his help...

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

15 Apr 2020 11:29 - 15 Apr 2020 11:42 #164052

by thefabricator03

Thanks Rod,

I have been reading the manual and it looks pretty straight forward. I was thinking about using an industrial potentiometer for speed control as it has a input for one.

The only thing I am not really sure of is how to work my E-stops into the wiring. When they are pressed I want to shut down power to the motor instantly. I will do some more reading but the VFD has 5 digital inputs I can use for E-stop control but I am not sure how to cut power from the motor without turning power off to the VFD.

Would it be as simple as wiring a Contactor in between the motor and VFD? And controlling the contactor with the VFD relay output? I am thinking I still need a way to stop the power in case the VFD malfunctions.

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

I have a tip for you. Its called a VFD (Variable Frequency Drive)

Seriously though other than the fact I have one sitting here I have never used one. I have a mate who lives in my street who is a bit of an expert on them. But the wiring is simple but there is a bit in the programming. He typically uses the existing knob as a speed control but you can use an external one. Sing out if you need help, I might be able to enlist his help...

Thanks Rod,

I have been reading the manual and it looks pretty straight forward. I was thinking about using an industrial potentiometer for speed control as it has a input for one.

The only thing I am not really sure of is how to work my E-stops into the wiring. When they are pressed I want to shut down power to the motor instantly. I will do some more reading but the VFD has 5 digital inputs I can use for E-stop control but I am not sure how to cut power from the motor without turning power off to the VFD.

Would it be as simple as wiring a Contactor in between the motor and VFD? And controlling the contactor with the VFD relay output? I am thinking I still need a way to stop the power in case the VFD malfunctions.

Last edit: 15 Apr 2020 11:42 by thefabricator03.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

15 Apr 2020 11:50 #164053

by thefabricator03

Since you mentioned it I went back and checked my spelling, I have been spelling it VDF for some unknown reason. Makes me paranoid now about what else I have been misspelling

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

I have a tip for you. Its called a VFD (Variable Frequency Drive)

Since you mentioned it I went back and checked my spelling, I have been spelling it VDF for some unknown reason. Makes me paranoid now about what else I have been misspelling

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

15 Apr 2020 11:52 #164054

by tommylight

I do have 2 of them here collecting dust, as luck would have it, yesterday i was reading the manual for the Dinverter one (3X380-480V, 2.2KW) and it can do RS485 AND RS422 !!! Nice, will have to mess more with it later on.

Some general tips:

Since it is going to be moving heavy stuff, set the spin up delay to 1 or 2 seconds, and spin down to 2 or 3 seconds.

Try to keep it around 50 or 60 Hz as normal motors will not like faster rotation and will eventually wear the bearings.

Some new VFD's have an Auto Tuning feature, use it if you can, it can greatly improve efficiency, hence less heat and strain on the motor.

Worm gear is the best choice for use in this case as it does not allow the constantly changing load to impact the motor, making it slip while rotating.

Get a simple adjustable timer, so you do not have to wait for it to finish, thank me later.

Almost all VFD's have inputs for a motor thermistor, find one and strap it to the motor, in case something gets stuck inside of the tumbler causing more load, it will save the motor from going up in smoke.

Replied by tommylight on topic Tumbler Build - For cleaning plasma cut parts.

What type ?Tom,

Do you have any tip on setting up my VDF?

I do have 2 of them here collecting dust, as luck would have it, yesterday i was reading the manual for the Dinverter one (3X380-480V, 2.2KW) and it can do RS485 AND RS422 !!! Nice, will have to mess more with it later on.

Some general tips:

Since it is going to be moving heavy stuff, set the spin up delay to 1 or 2 seconds, and spin down to 2 or 3 seconds.

Try to keep it around 50 or 60 Hz as normal motors will not like faster rotation and will eventually wear the bearings.

Some new VFD's have an Auto Tuning feature, use it if you can, it can greatly improve efficiency, hence less heat and strain on the motor.

Worm gear is the best choice for use in this case as it does not allow the constantly changing load to impact the motor, making it slip while rotating.

Get a simple adjustable timer, so you do not have to wait for it to finish, thank me later.

Almost all VFD's have inputs for a motor thermistor, find one and strap it to the motor, in case something gets stuck inside of the tumbler causing more load, it will save the motor from going up in smoke.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

15 Apr 2020 12:01 #164055

by tommylight

Replied by tommylight on topic Tumbler Build - For cleaning plasma cut parts.

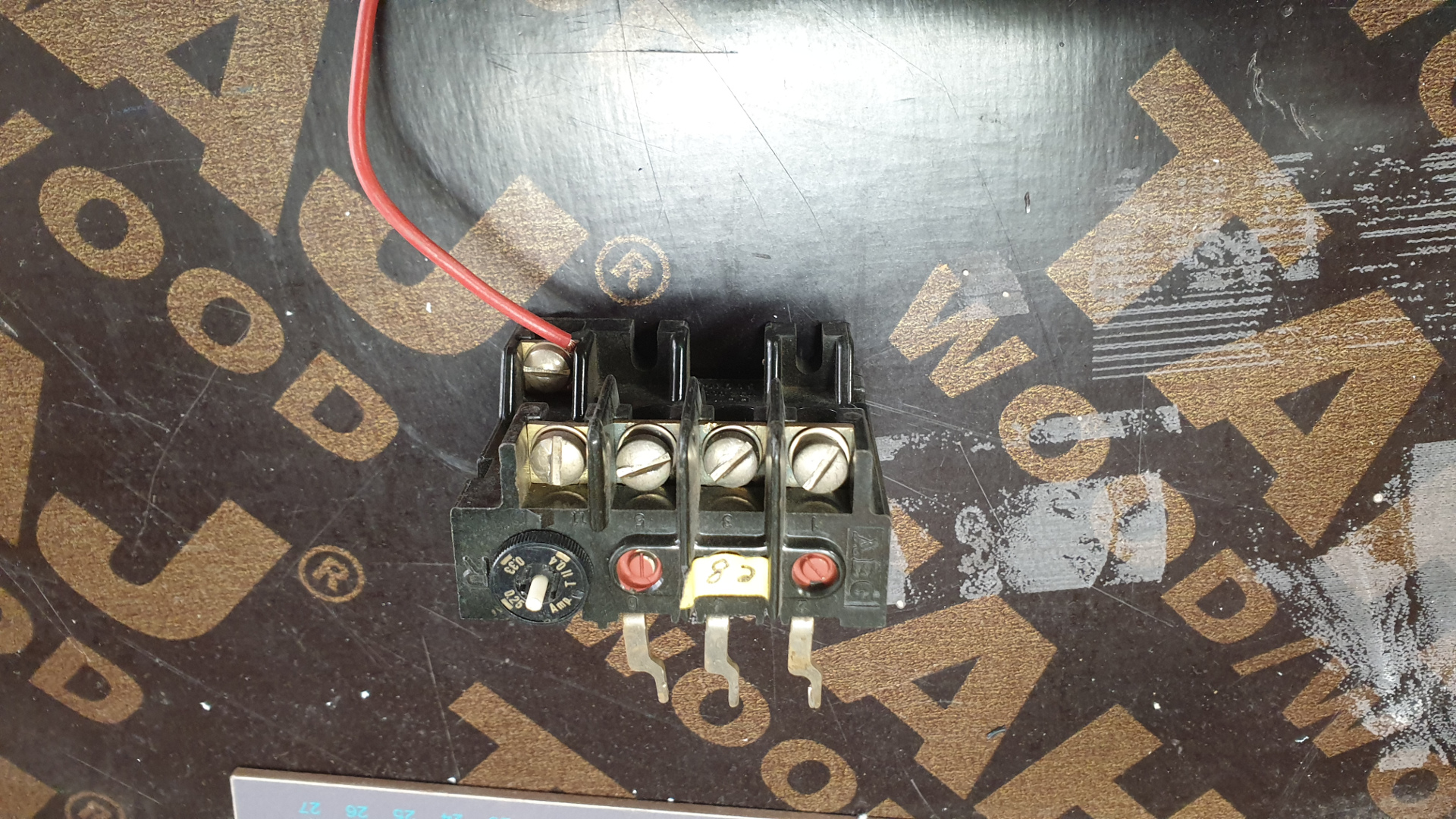

It can also be done without a VFD, just find a thermal fuse, 3 phase. It will work, but you loose the ability to adjust the speed ( although some motors can do 2 speeds depending on if wired as star or triangle ).

I do have some of the those thermal fuses here, they are made to be attached to the relay directly and and can save the motor if any of the phases get loaded more than it should. They are all adjustable as to the current they will trip.

I do have some of the those thermal fuses here, they are made to be attached to the relay directly and and can save the motor if any of the phases get loaded more than it should. They are all adjustable as to the current they will trip.

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.213 seconds