Tumbler Build - For cleaning plasma cut parts.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

18 Jul 2020 07:17 #175022

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Today I made some sprockets for the roller door chain drive,

Took me five revisons to get the sprokets sitting on the chain correctly. Plasma really is a blunt axe but these should work fine.

I will weld on a piece of pipe with two grub screws to hold them onto the shafts,

Took me five revisons to get the sprokets sitting on the chain correctly. Plasma really is a blunt axe but these should work fine.

I will weld on a piece of pipe with two grub screws to hold them onto the shafts,

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

18 Jul 2020 07:34 #175023

by Clive S

Replied by Clive S on topic Tumbler Build - For cleaning plasma cut parts.

Is there no end to your talents

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

18 Jul 2020 07:42 - 18 Jul 2020 07:42 #175025

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Lol Thanks Clive. In the next couple of years I have some pretty big projects lined up. Stay tuned.

Last edit: 18 Jul 2020 07:42 by thefabricator03.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

18 Jul 2020 13:08 #175028

by machinedude

Replied by machinedude on topic Tumbler Build - For cleaning plasma cut parts.

have to give you credit you get into some pretty cool builds. sprockets would not have been on list of things to cut with plasma but it looks like you proved me wrong in my thinking

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

18 Jul 2020 13:13 - 18 Jul 2020 13:19 #175029

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Sometimes you need to find a way to make the tools you have work.

The sprockets have a bit of taper. I had to lower the feed rate right down to try to eliminate most of the taper and it worked, also I had to reduce the scale slightly of the sprocket diameter to work with the plasma cuts. If I had them laser cut they would of been perfect the first time but I am sure they will work fine in my roller door application. I would not want to use them for a motor bike or such.

I see building a laser cutter in my future

The sprockets have a bit of taper. I had to lower the feed rate right down to try to eliminate most of the taper and it worked, also I had to reduce the scale slightly of the sprocket diameter to work with the plasma cuts. If I had them laser cut they would of been perfect the first time but I am sure they will work fine in my roller door application. I would not want to use them for a motor bike or such.

I see building a laser cutter in my future

Last edit: 18 Jul 2020 13:19 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

18 Jul 2020 13:29 #175031

by tommylight

Replied by tommylight on topic Tumbler Build - For cleaning plasma cut parts.

Pat yourself on the back as i can not reach from here!

Nicely done.

Nicely done.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

18 Jul 2020 13:30 #175032

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Thanks Tom, It means much to me coming from you.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

18 Jul 2020 13:56 - 18 Jul 2020 13:59 #175037

by machinedude

Replied by machinedude on topic Tumbler Build - For cleaning plasma cut parts.

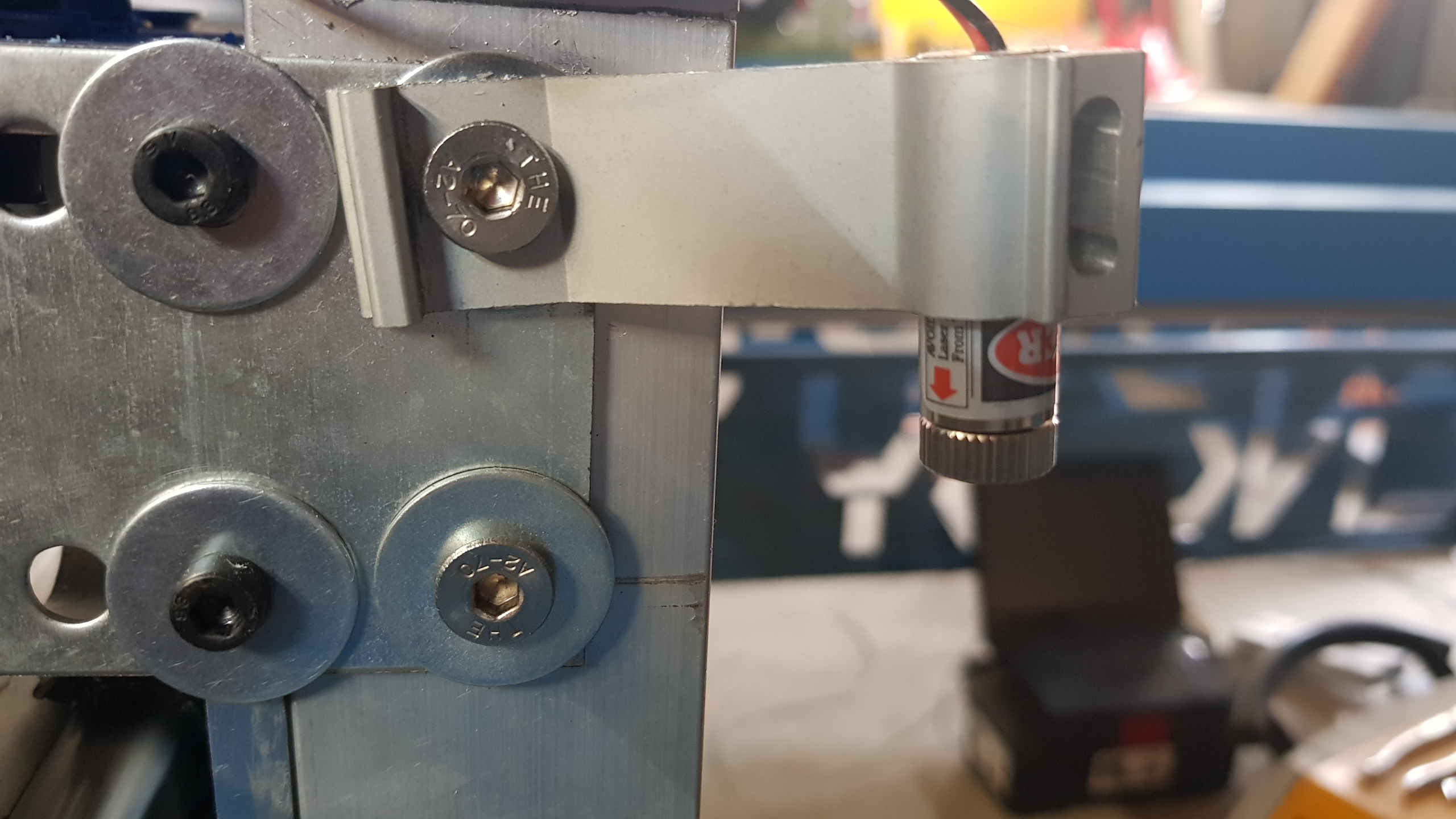

we got a new one a few years back the laser cutting is a nice process to have. the one we got was a Co2 laser but i think the fiber optic ones are getting a lot better. the Mitsubishi ex series was what they got and it has two 5 x 10 tables. the one can be loaded while the other one is cutting and has a pallet changer so it can cut non stop. nice machines.

Attachments:

Last edit: 18 Jul 2020 13:59 by machinedude.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

18 Jul 2020 14:01 - 18 Jul 2020 14:03 #175038

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

I dont think the one I will build will be as fancy but it will be far far cheaper!

I was quoted around $900K for a similar unit to the one you posted a picture of. Problem I see with all those high dollar machines is the vendor lock in. I have grown to loath proprietary control systems! I will never buy something like that, that I need to get a special technician out to change a simple setting! At $500 an hour as well. No Thanks Lol.

I was quoted around $900K for a similar unit to the one you posted a picture of. Problem I see with all those high dollar machines is the vendor lock in. I have grown to loath proprietary control systems! I will never buy something like that, that I need to get a special technician out to change a simple setting! At $500 an hour as well. No Thanks Lol.

Last edit: 18 Jul 2020 14:03 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

18 Jul 2020 14:58 #175051

by tommylight

Replied by tommylight on topic Tumbler Build - For cleaning plasma cut parts.

A bit off topic, but just goes to show to what extent i molest my brain when building something, granted i can find the parts:

Left are black M5 screws, right are white M6 screws, all with 4mm allen wrench.

Above 4x M6 screws, below is an M8 screw, all with 5mm allen wrench.

Up until the last 3 machines i built, looks were not on the priority list at all, functionality was. Now that has changed, but it made building the machine much more time consuming.

Left are black M5 screws, right are white M6 screws, all with 4mm allen wrench.

Above 4x M6 screws, below is an M8 screw, all with 5mm allen wrench.

Up until the last 3 machines i built, looks were not on the priority list at all, functionality was. Now that has changed, but it made building the machine much more time consuming.

Attachments:

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.139 seconds