My Newb Plasma Table Attempted Build

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

02 Aug 2020 09:41 #176882

by rodw

I much prefer written content becasue I can read about 10 x faster than I can listen to the same content. I have no idea what all the fuss is over with Audible!

Replied by rodw on topic My Newb Plasma Table Attempted Build

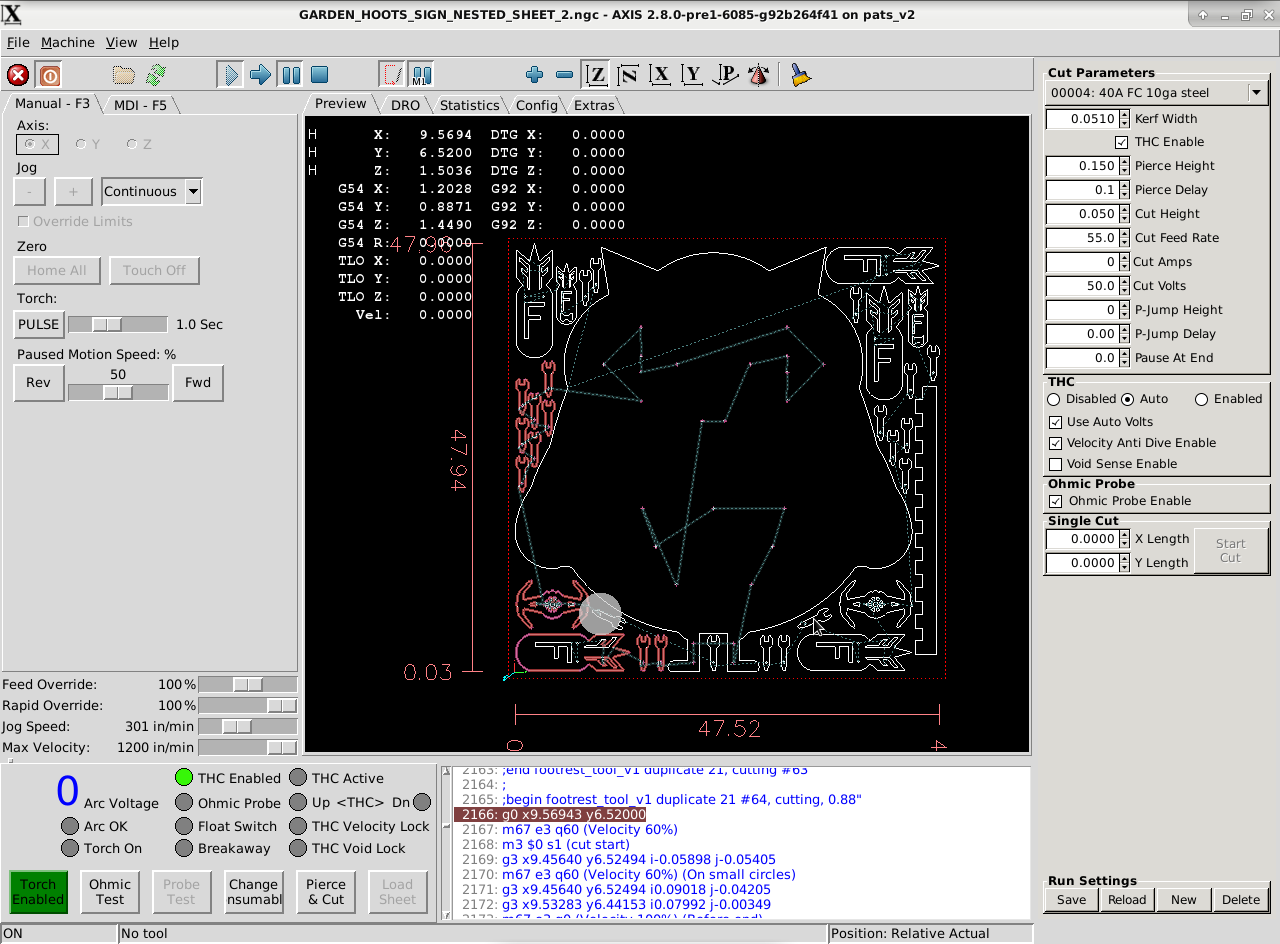

And i do like motion pictures, i watch everything at 1.5X or 1.75X speed. Everything.After 7 hours I cut this...the vid is for Tommy, he likes motion-pictures lmao!

I much prefer written content becasue I can read about 10 x faster than I can listen to the same content. I have no idea what all the fuss is over with Audible!

The following user(s) said Thank You: tommylight, dvn4life1972

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Aug 2020 15:07 #176895

by dvn4life1972

Me too! Ever since Benny Hill I can't help myself!

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

And i do like motion pictures, i watch everything at 1.5X or 1.75X speed. Everything.

Me too! Ever since Benny Hill I can't help myself!

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

02 Aug 2020 15:15 #176896

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

My THCAD-5 arrived on Friday. I never did move the electronics into the bigger/nicer enclosure just yet as I was waiting for that. Plus, inspired by Rod's build pics, I want to get some Meanwell DIN mounted power supplies and really tidy everything up nicely. The ohmic hypersensing will be the next thing on this one.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

07 Aug 2020 01:09 #177563

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

07 Aug 2020 01:31 #177564

by thefabricator03

Replied by thefabricator03 on topic My Newb Plasma Table Attempted Build

I have been having trouble with our large compressor that runs our workshop and the plasma, When my guys use any air tools when the plasma is cutting it stops the plasma. I have partially solved the problem but is not hooked up yet, another project.

Please Log in or Create an account to join the conversation.

- dvn4life1972

- Offline

- Platinum Member

-

Less

More

- Posts: 401

- Thank you received: 168

07 Aug 2020 01:46 #177565

by dvn4life1972

Replied by dvn4life1972 on topic My Newb Plasma Table Attempted Build

Ha such really phenomenal gear compared to my little 21gal on wheels. Very nice, maybe I will have a nicer shop in the near future.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

07 Aug 2020 02:21 #177567

by thefabricator03

Replied by thefabricator03 on topic My Newb Plasma Table Attempted Build

Before I brought the big girl I went through my Hypertherm 125 user manual and it said It required 260 LMP, I brought the below small unit and hooked it up and ran a sheet out of purlin cleats. The job goes for 3.5 hours. The small unit kept running the whole time and after about and hour and a half would not hold pressure. I think It over heated due the the constant demands. I returned the compressor for a full refund and decided to buy a decent unit.

www.gasweld.com.au/air-compressor-3-2-hp...ta65-3-cylinder-pump

www.gasweld.com.au/air-compressor-3-2-hp...ta65-3-cylinder-pump

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Aug 2020 04:28 #177571

by machinedude

Replied by machinedude on topic My Newb Plasma Table Attempted Build

we have a 25 HP screw compressor with two reservoir tanks that are about 125 gallons each. it does pretty good keeping up with the machining centers and what ever small air tools that get used on top of that. so for dealing with 10 milling machines 4 lathes and two lasers it does pretty well so far. i was impressed with how well it keeps up. i think that the lasers run mostly on nitrogen though so those probably don't count for to much air use.

screw compressors are a bit expensive but they work really well from what i have seen.

screw compressors are a bit expensive but they work really well from what i have seen.

The following user(s) said Thank You: thefabricator03, dvn4life1972

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

07 Aug 2020 05:08 #177573

by thefabricator03

Replied by thefabricator03 on topic My Newb Plasma Table Attempted Build

Yeah screw compressors are very nice, for one the size I needed to do everything would cost me $15k AUD. They also have the benefit that they dont generate much moisture so you dont need a large dryer. Dryers are not cheap for a good one.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

07 Aug 2020 05:31 #177575

by machinedude

Replied by machinedude on topic My Newb Plasma Table Attempted Build

i think they said ours cost around 10k so yes they can be expensive. we have the air dryer in the system as well. most commercial machines don't deal with water in the air supply very well. Plasma applications are no different. so if you are doing the volume of work to justify the extra cost a air drying system is money well spent to save you some headaches later on.

The following user(s) said Thank You: dvn4life1972

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.152 seconds