1.2m x 0.6m plasma, <£2k questions!:

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21220

- Thank you received: 7246

30 Jun 2020 22:51 #173230

by tommylight

Replied by tommylight on topic 1.2m x 0.6m plasma, <£2k questions!:

B

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

30 Jun 2020 23:57 #173253

by andypugh

Replied by andypugh on topic 1.2m x 0.6m plasma, <£2k questions!:

Late to the party (Working from home, bizarrely, means that for some reason I don't do the forums at lunchtime)

For motors / drives etc I have uses Zapp Automation a fair bit:

www.zappautomation.co.uk

I want to design a folding, core-XY plasma. Just for the fun of it.

For motors / drives etc I have uses Zapp Automation a fair bit:

www.zappautomation.co.uk

I want to design a folding, core-XY plasma. Just for the fun of it.

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3929

01 Jul 2020 09:40 #173301

by rodw

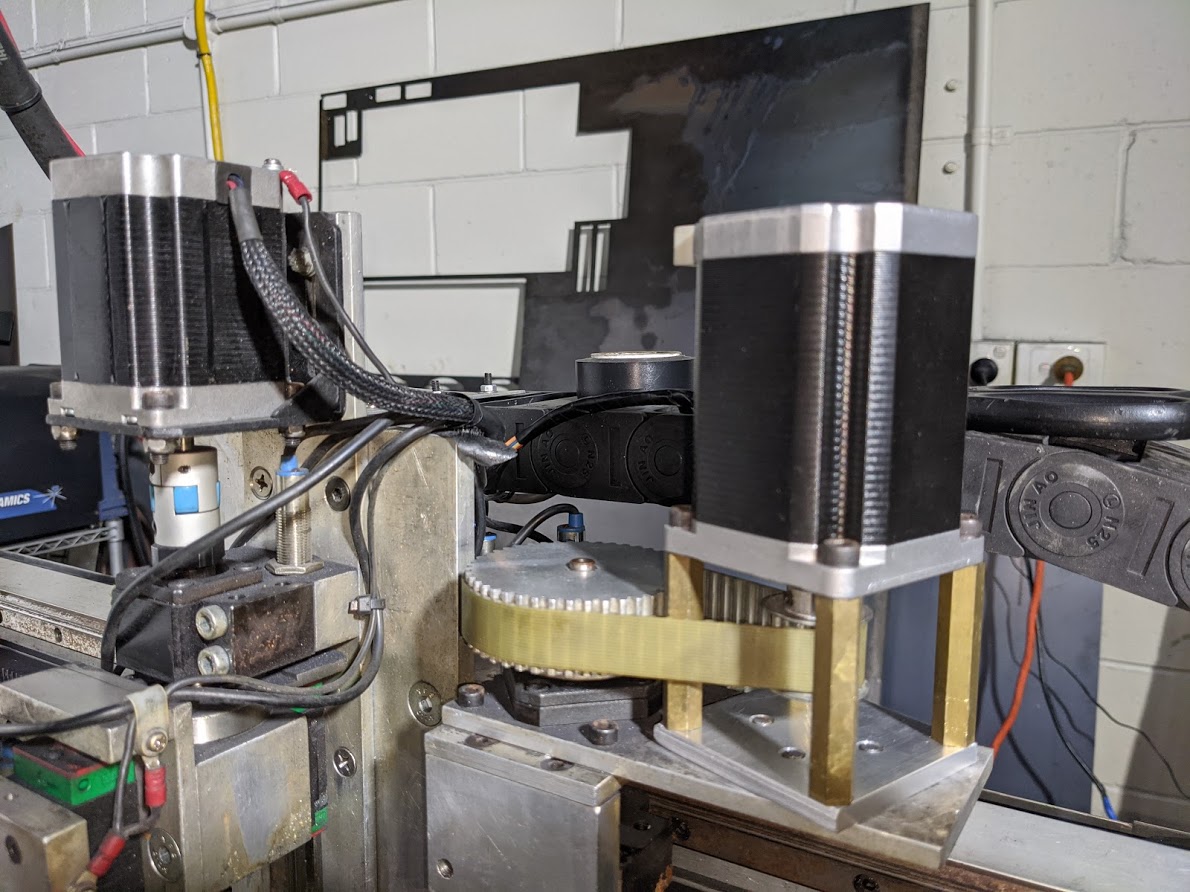

Chris, I think I'd go with B. I don't think it would be too hard to mount the stepper on legs like I like to use. If the mounting plate went right round the motor, you should be able to mount the legs on the motor side instead of the pulley side. How easy would that be to service?

Replied by rodw on topic 1.2m x 0.6m plasma, <£2k questions!:

So belt position...?

I'm just playing with the CAD for giggles...

Do people think there would be a particularly large difference in performance / stiffness with either A or B belt location for the Y axis?

For simplicity, bolting the motor direct to the carriage plate and running the belt below the linear rail (image A below) would be easier, but can't help but think having the belt directly below the table tube seems a better bet (image B below). B would need an extra plate and mount though obvisously to move the motor inboard...

Thoughts? Or am I just being pedantic...?

Chris.

Chris, I think I'd go with B. I don't think it would be too hard to mount the stepper on legs like I like to use. If the mounting plate went right round the motor, you should be able to mount the legs on the motor side instead of the pulley side. How easy would that be to service?

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

01 Jul 2020 12:02 #173311

by andypugh

Replied by andypugh on topic 1.2m x 0.6m plasma, <£2k questions!:

I would go with "C"

ie, put the ball slide under the side member so muck doesn't fall in it.

ie, put the ball slide under the side member so muck doesn't fall in it.

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

01 Jul 2020 12:05 #173312

by andypugh

Steppers on legs is popular and effective. And I hate it

If I was building a plasma it would almost certainly be a Core-XY setup.

Replied by andypugh on topic 1.2m x 0.6m plasma, <£2k questions!:

Chris, I think I'd go with B. I don't think it would be too hard to mount the stepper on legs like I like to use.

Steppers on legs is popular and effective. And I hate it

If I was building a plasma it would almost certainly be a Core-XY setup.

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

02 Jul 2020 15:47 #173428

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

I've got four 425 ozin NEMA 23 with 10mm output shaft.

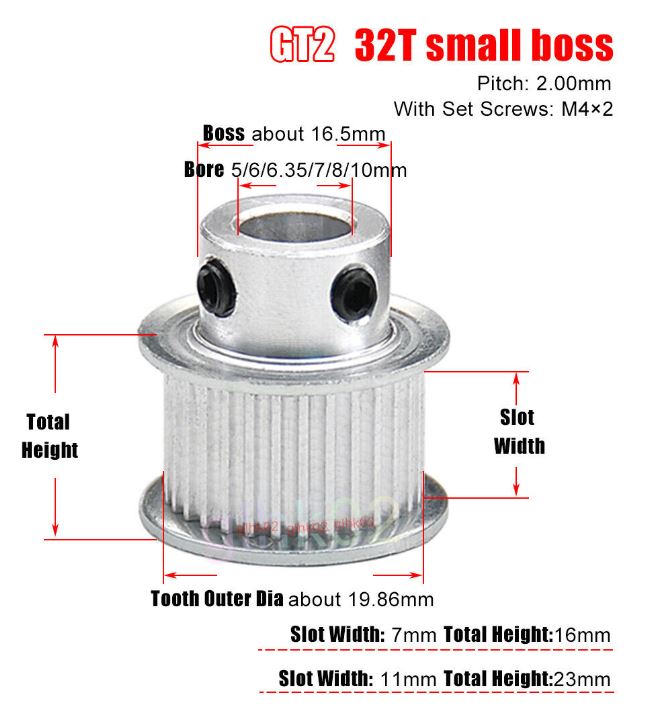

How do people calculate what gearing is best suited to a small plasma table? Tommy's plasma primer suggests 16 to 20T on the drive pulley, but I can't seem to find any 10mm bore pulleys with such few teeth.

I'm thinking 10mm GT2 belt but 6mm probably would be stiff enough?

Is gear reduction sensible here?

Ta for any help,

Chris.

P.S. is there any resource around to calculate or help direct what gearing is best with the torque curve of the motor, supply voltage, maximum / minimum velocities, etc.

How do people calculate what gearing is best suited to a small plasma table? Tommy's plasma primer suggests 16 to 20T on the drive pulley, but I can't seem to find any 10mm bore pulleys with such few teeth.

I'm thinking 10mm GT2 belt but 6mm probably would be stiff enough?

Is gear reduction sensible here?

Ta for any help,

Chris.

P.S. is there any resource around to calculate or help direct what gearing is best with the torque curve of the motor, supply voltage, maximum / minimum velocities, etc.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

02 Jul 2020 16:04 #173431

by andypugh

Well, if you want GT2 and 16T then that's a diameter of 16 x 2 / pi = 10.18 mm, so there would be nothing left of the pulley if you bored a 10mm hole.

I have a feeling that GT2 is a US (but metric) belt standard. It doesn't seem to be stocked by the usual suspects (RS, HPC Gears, Bearing Boys) . It is 3D printer-scale belt, I would be expecting to see at least T5 x 15 used on a plasma cutter.

www.ebay.co.uk/itm/273825972643 has it at at <£4/m

Replied by andypugh on topic 1.2m x 0.6m plasma, <£2k questions!:

Tommy's plasma primer suggests 16 to 20T on the drive pulley, but I can't seem to find any 10mm bore pulleys with such few teeth.

Well, if you want GT2 and 16T then that's a diameter of 16 x 2 / pi = 10.18 mm, so there would be nothing left of the pulley if you bored a 10mm hole.

I'm thinking 10mm GT2 belt but 6mm probably would be stiff enough?

I have a feeling that GT2 is a US (but metric) belt standard. It doesn't seem to be stocked by the usual suspects (RS, HPC Gears, Bearing Boys) . It is 3D printer-scale belt, I would be expecting to see at least T5 x 15 used on a plasma cutter.

www.ebay.co.uk/itm/273825972643 has it at at <£4/m

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21220

- Thank you received: 7246

02 Jul 2020 16:08 #173432

by tommylight

There are 15 tooth pulleys with 8mm bore for HTD3 belts that would still be usable for a small plasma with microstepping drives, but they are not cheap.

That brings us to the question: where did you find Nema23 motors with 10mm shaft ? I have 6, 6.35, 8, some 5mm and even some 7mm shaft ones, but never 10 !

Replied by tommylight on topic 1.2m x 0.6m plasma, <£2k questions!:

That is usable with microstepping drives, the ideal would be between 10 and 20mm per motor revolution on stepper systems......... plasma primer suggests 16 to 20T on the drive pulley,

There are 15 tooth pulleys with 8mm bore for HTD3 belts that would still be usable for a small plasma with microstepping drives, but they are not cheap.

That brings us to the question: where did you find Nema23 motors with 10mm shaft ? I have 6, 6.35, 8, some 5mm and even some 7mm shaft ones, but never 10 !

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

02 Jul 2020 19:52 #173447

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

Stepper motors are from StepperOnline...

www.omc-stepperonline.com/nema-23-steppe...epper-motor-cnc.html

Didn't think enough about drive pulleys with 10mm bore and low tooth count when I bought them. They do seem nicely made though.

A 20T GT2 OD is 12mm, so one revolution would be 37.7mm per single revolution. Far from your 10 to 20mm suggestion Tommy.

What is a maximum distance per rotation that is still usable? Driver is a DM556Y shown below.

C.

www.omc-stepperonline.com/nema-23-steppe...epper-motor-cnc.html

Didn't think enough about drive pulleys with 10mm bore and low tooth count when I bought them. They do seem nicely made though.

A 20T GT2 OD is 12mm, so one revolution would be 37.7mm per single revolution. Far from your 10 to 20mm suggestion Tommy.

What is a maximum distance per rotation that is still usable? Driver is a DM556Y shown below.

C.

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

02 Jul 2020 19:56 #173448

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.268 seconds