1.2m x 0.6m plasma, <£2k questions!:

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

02 Jul 2020 20:22 #173449

by rodw

Replied by rodw on topic 1.2m x 0.6m plasma, <£2k questions!:

As Andy said GT is a US standard which is rapidly waning.

I've just been working through this with a company here in Australia and Optibelt in Germany. Optibelt have good resources on their site.

Look for a AT5 belt in 16mm or 25mm for motion. Minimum Pulley should start from 12 teeth, 17.9 mm OD, Normally pulleys are pilot bore so you bore them out to suit on lathe. I just converted 1/4" to 10mm the other day. Optibelt were worried about water from a water table and suggested to use AT10 which they make with stainless steel reinforcing bands that won't rust but then you need to go to an AT10 belt and the minimum pulley size goes up. (but I think AT5 will be fine on a small machine).

The work I've done suggests that 3:1 reduction and a 20 tooth pulley (30.6mm diameter)

I've just been working through this with a company here in Australia and Optibelt in Germany. Optibelt have good resources on their site.

Look for a AT5 belt in 16mm or 25mm for motion. Minimum Pulley should start from 12 teeth, 17.9 mm OD, Normally pulleys are pilot bore so you bore them out to suit on lathe. I just converted 1/4" to 10mm the other day. Optibelt were worried about water from a water table and suggested to use AT10 which they make with stainless steel reinforcing bands that won't rust but then you need to go to an AT10 belt and the minimum pulley size goes up. (but I think AT5 will be fine on a small machine).

The work I've done suggests that 3:1 reduction and a 20 tooth pulley (30.6mm diameter)

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21029

- Thank you received: 7163

02 Jul 2020 20:56 #173451

by tommylight

Replied by tommylight on topic 1.2m x 0.6m plasma, <£2k questions!:

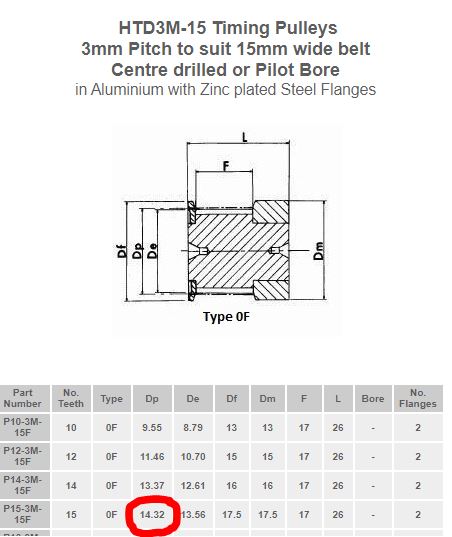

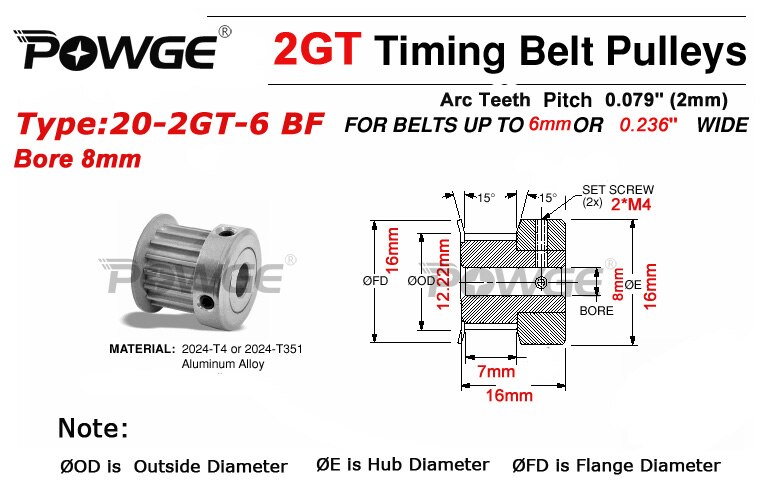

On pulleys the outer diameter is useless, the important part is the pitch that is 2mm for GT2 and 3mm for HTD3 and 5MM for HTD5 etc, and the number of teeth.

So a 20 tooth GT2 will move 40mm for one rotation, a 15 tooth HTD3 will move 45mm for one rotation etc.

Drives that do proper microstepping can work even with bigger pulleys, the resolution and repeatability will suffer a bit, but still good enough for hobby plasma cutting.

Belts, up to 1m length you can use 6mm wide ones if the gantry is very light and the belt is on both sides, hell i did even longer ones with 6mm but the acceleration had to be quite low to remove the springiness of the belt on fast direction switching. Up to 10 or 12 KG in total for gantry, floating head and torch should be just fine with 6mm on both sides. That is all for armoured belts with stainless steel wires or carbon fibre reinforcement inside, not the cheap ones. I exclusively buy armoured ones.

If you are looking to buy the pulleys and belts, get the HTD3 10mm wide ones with 15 tooth, later you can get cheap reduction with GT2 belts and use the existing HTD3 for the final drive, so if you want a bigger machine you would have to buy longer belts and nothing more.

By far the cheapest reduction for small machines with 6mm wide belts are from a seller named "ideaformer1" on ebay, he has 3:1 reductions for 5$ a set, very good quality and never fails to deliver. Beware that he has a lot of same sets for different prices, so do a little searching to find them.

So a 20 tooth GT2 will move 40mm for one rotation, a 15 tooth HTD3 will move 45mm for one rotation etc.

Drives that do proper microstepping can work even with bigger pulleys, the resolution and repeatability will suffer a bit, but still good enough for hobby plasma cutting.

Belts, up to 1m length you can use 6mm wide ones if the gantry is very light and the belt is on both sides, hell i did even longer ones with 6mm but the acceleration had to be quite low to remove the springiness of the belt on fast direction switching. Up to 10 or 12 KG in total for gantry, floating head and torch should be just fine with 6mm on both sides. That is all for armoured belts with stainless steel wires or carbon fibre reinforcement inside, not the cheap ones. I exclusively buy armoured ones.

If you are looking to buy the pulleys and belts, get the HTD3 10mm wide ones with 15 tooth, later you can get cheap reduction with GT2 belts and use the existing HTD3 for the final drive, so if you want a bigger machine you would have to buy longer belts and nothing more.

By far the cheapest reduction for small machines with 6mm wide belts are from a seller named "ideaformer1" on ebay, he has 3:1 reductions for 5$ a set, very good quality and never fails to deliver. Beware that he has a lot of same sets for different prices, so do a little searching to find them.

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

04 Jul 2020 22:38 #173632

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

Thanks both! When I say OD, I mean pitch diameter.

Your examples make sense Tommy. 38.39mm for the GT2 and 44.98mm for the HTD.

News to me too, on the pilot bore rodw, thanks for that. Will use the lathe to sort to 10mm ID.

With a 30.6mm PD and 3:1 reduction, you'll have around 32mm per revolution. What microstepping, motor, torque, maximum velocity, etc variables did you use to settle on 32mm?

Thanks all,

Chris.

Your examples make sense Tommy. 38.39mm for the GT2 and 44.98mm for the HTD.

News to me too, on the pilot bore rodw, thanks for that. Will use the lathe to sort to 10mm ID.

With a 30.6mm PD and 3:1 reduction, you'll have around 32mm per revolution. What microstepping, motor, torque, maximum velocity, etc variables did you use to settle on 32mm?

Thanks all,

Chris.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

04 Jul 2020 23:54 #173637

by rodw

We used a proprietary model. Basically it calculates the torque required at the pinion to meet requirements then when you enter the details of a motor, It calculates the amps and voltage the motor needs to be run at to meet the requirements. The hard part is to find a motor where the required amps is less than what the motor is rated for and stays within a reasonable voltage range (eg. requiring 115 volts when you only want to use a 90 volt supply is a fail). I'm hoping for 5 m/s/s acceleration

Replied by rodw on topic 1.2m x 0.6m plasma, <£2k questions!:

With a 30.6mm PD and 3:1 reduction, you'll have around 32mm per revolution. What microstepping, motor, torque, maximum velocity, etc variables did you use to settle on 32mm?

Thanks all,

Chris.

We used a proprietary model. Basically it calculates the torque required at the pinion to meet requirements then when you enter the details of a motor, It calculates the amps and voltage the motor needs to be run at to meet the requirements. The hard part is to find a motor where the required amps is less than what the motor is rated for and stays within a reasonable voltage range (eg. requiring 115 volts when you only want to use a 90 volt supply is a fail). I'm hoping for 5 m/s/s acceleration

The following user(s) said Thank You: WinstonTodge

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

12 Dec 2021 23:32 - 12 Dec 2021 23:33 #228960

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

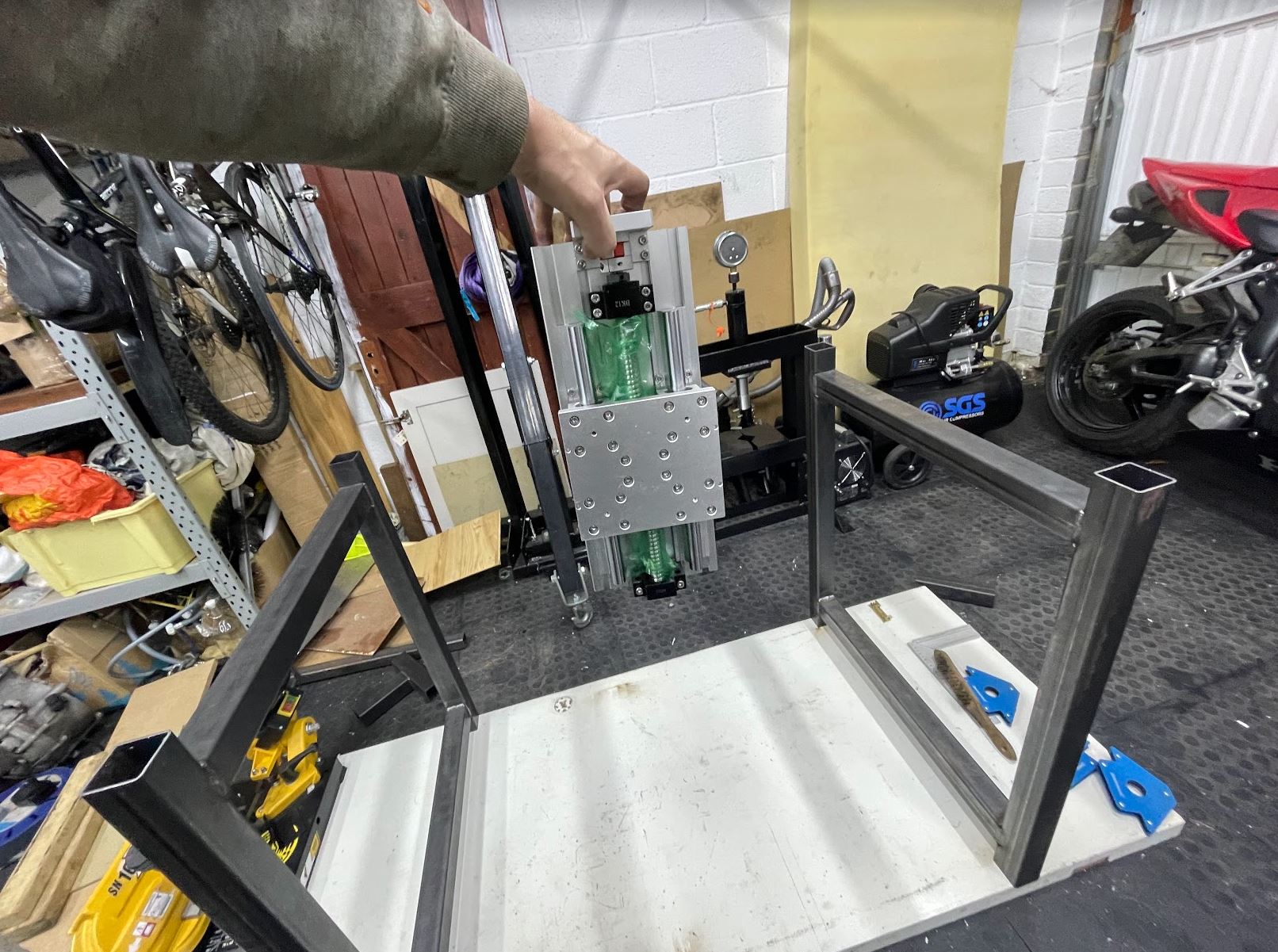

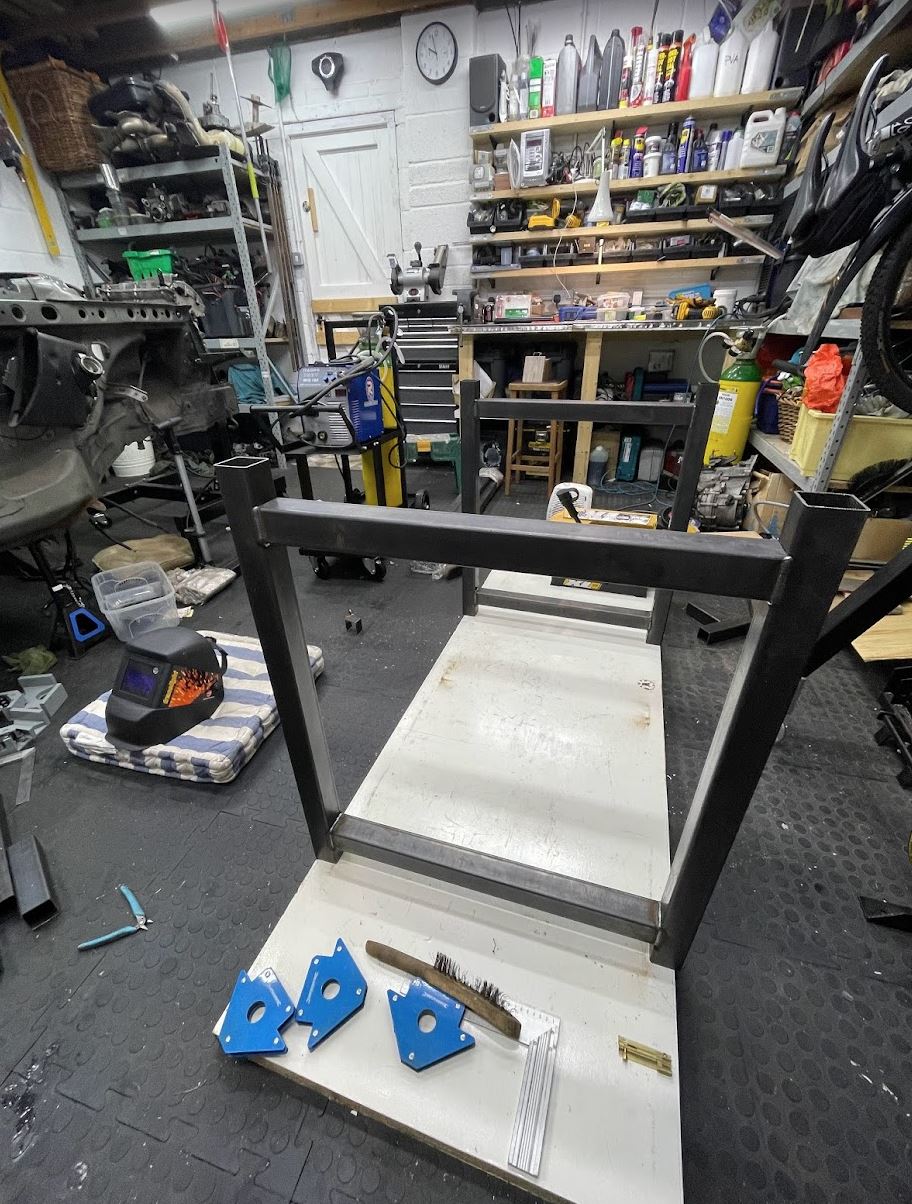

Well I'm back to it after such a long break... Real life getting in the way again.

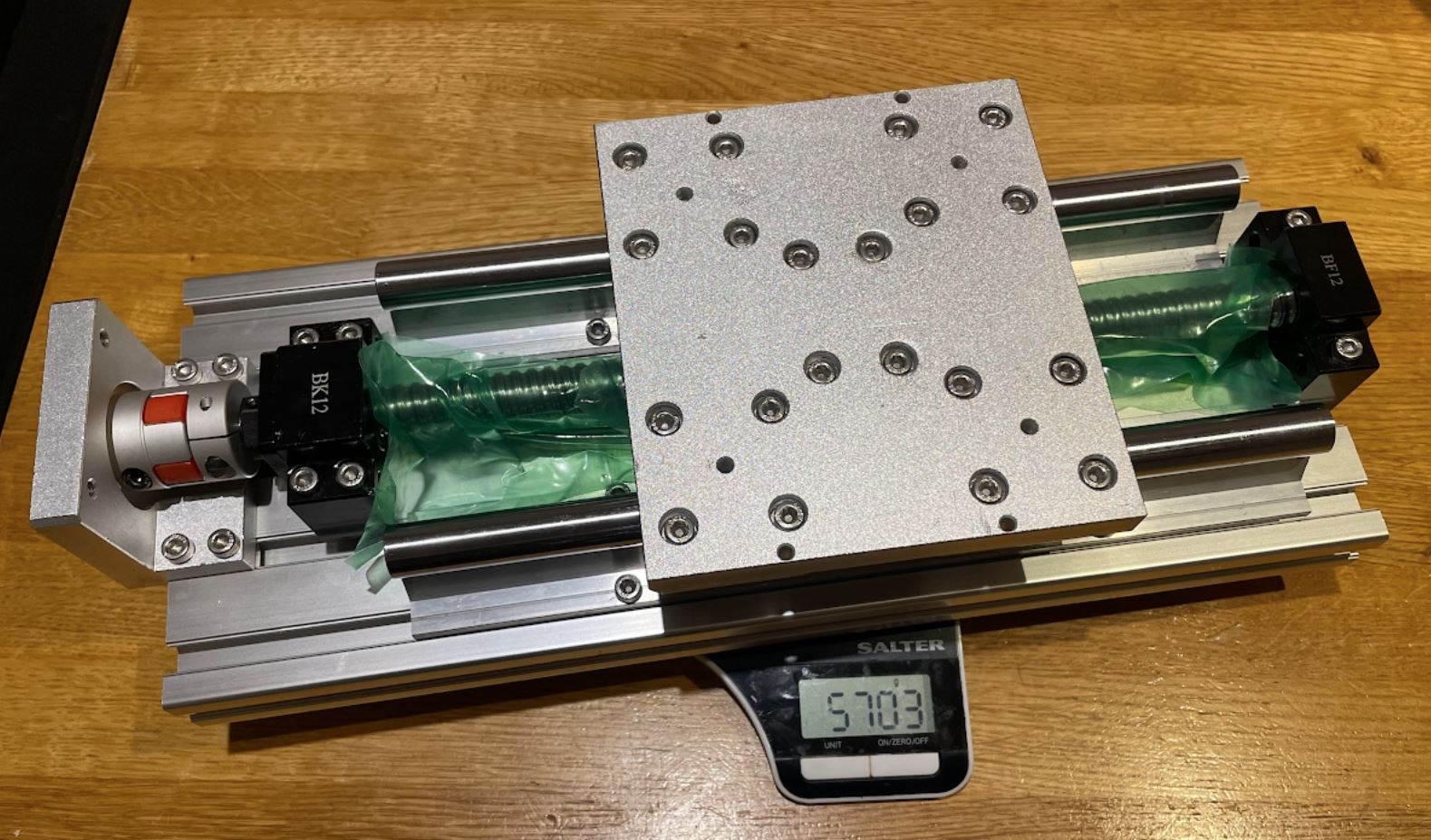

I've started fabricating the frame tonight and am starting to think that my z axis linear stage at 300mm 1605 ball screw is a little over the top! It's 5.7kg! I've got some 425 ozin NEMA23 to drive the Y gantry. Will I need to put the stage on a diet?! Or just limit accelerations / decelerations? I'm not worried about ultimate speed of cut, just accuracy.

Still need to get some belts and pulleys...

I've started fabricating the frame tonight and am starting to think that my z axis linear stage at 300mm 1605 ball screw is a little over the top! It's 5.7kg! I've got some 425 ozin NEMA23 to drive the Y gantry. Will I need to put the stage on a diet?! Or just limit accelerations / decelerations? I'm not worried about ultimate speed of cut, just accuracy.

Still need to get some belts and pulleys...

Attachments:

Last edit: 12 Dec 2021 23:33 by WinstonTodge. Reason: Insert pics.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

12 Dec 2021 23:39 #228962

by rodw

Replied by rodw on topic 1.2m x 0.6m plasma, <£2k questions!:

Yes, it will be fine with 48v power. They are surprisingly heavy.

Just watch the rubber insert in the coupler. I checked mine the other day and it was gone! Wasn't a cheap ebay one either!

Just watch the rubber insert in the coupler. I checked mine the other day and it was gone! Wasn't a cheap ebay one either!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21029

- Thank you received: 7163

12 Dec 2021 23:48 #228965

by tommylight

Replied by tommylight on topic 1.2m x 0.6m plasma, <£2k questions!:

No pictures of the "farewell party" ?... I checked mine the other day and it was gone! ...

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11544

- Thank you received: 3871

13 Dec 2021 00:20 #228970

by rodw

If you insist photos.app.goo.gl/vxh6an5fJtDS7zWL8

Replied by rodw on topic 1.2m x 0.6m plasma, <£2k questions!:

It rather rudely departed without so much as a goodbye!

... I checked mine the other day and it was gone! ...

No pictures of the "farewell party" ?

If you insist photos.app.goo.gl/vxh6an5fJtDS7zWL8

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21029

- Thank you received: 7163

13 Dec 2021 01:30 #228978

by tommylight

Replied by tommylight on topic 1.2m x 0.6m plasma, <£2k questions!:

The audacity ... LOL

No pictures of the "farewell party" ?... I checked mine the other day and it was gone! ...

It rather rudely departed without so much as a goodbye!

If you insist photos.app.goo.gl/vxh6an5fJtDS7zWL8

Please Log in or Create an account to join the conversation.

- WinstonTodge

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

16 Dec 2021 21:40 #229206

by WinstonTodge

Replied by WinstonTodge on topic 1.2m x 0.6m plasma, <£2k questions!:

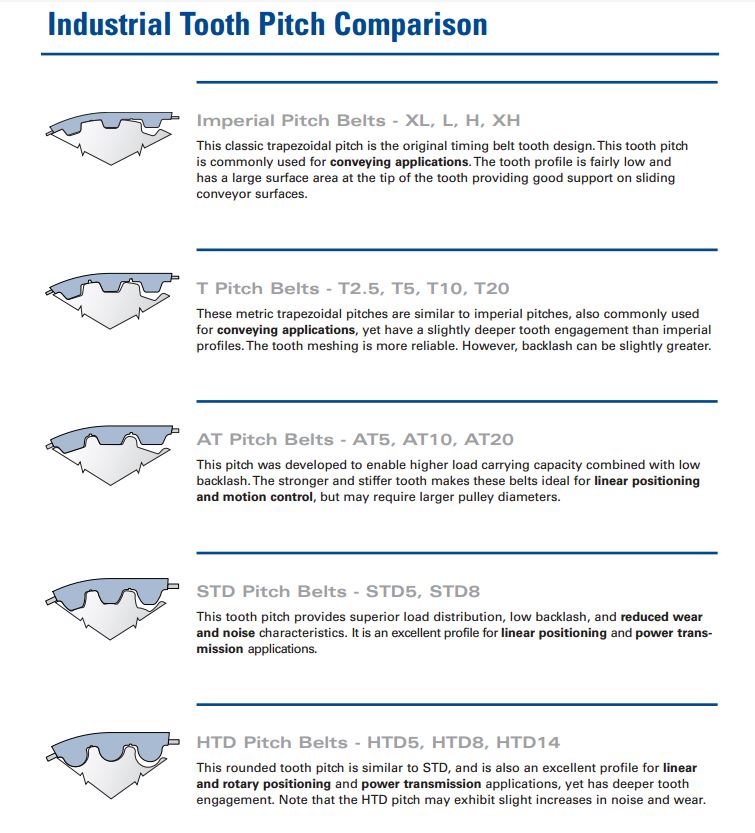

Just putting this here, as some really interesting tucked away in there...

file.lasersaur.com/docs-thirdparty/The_W..._of_Timing_Belts.pdf

And this was a nice top level summary...

file.lasersaur.com/docs-thirdparty/The_W..._of_Timing_Belts.pdf

And this was a nice top level summary...

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.223 seconds