Post Processor for LinuxCNC and PlasmaC

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11527

- Thank you received: 3860

If you define a F word like the F 3.937 then linuxcnc will use that as the feed rate. I don't think they should be there.

Cheers, Phill.

The whole intent of this POST was to retain plasmac as the master of settings and the only sheetcam parameter used would be the tool number. Its not possible to delete the default variables in a Sheetcam tool setting but Les has suggested he might be able to hide them in the GUI based on a post processor setting so the only sheetcam setting visible when using the final POST is the tool number and name. So yes, they should be there.

In sheetcam speak, the M190 to select the tools is called in onToolChange() but setting the feed rate is deferred until onPenDown().so it is inserted just before the M3.

This makes sense as if a new tool is loaded M190 will select the tool and the plasmac feedrate is invoked every piearce before the M3. Its possible, it could be set onToolChange() but it seems safer this way which follows the logic in the post I started with.

JTK -- Did you notice that in 2019 Less is still talking about adding new features to Sheetcam?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I don't fully understand what you mean by this. Plasmac doesn't set the feed rate, gcode gets the feed rate from plasmac and any subsequent F words in gcode will change the feed rate.The whole intent of this POST was to retain plasmac as the master of settings and the only sheetcam parameter used would be the tool number. Its not possible to delete the default variables in a Sheetcam tool setting but Les has suggested he might be able to hide them in the GUI based on a post processor setting so the only sheetcam setting visible when using the final POST is the tool number and name. So yes, they should be there.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11527

- Thank you received: 3860

Rule number one with data management is never to store the same piece of data in two places. So therefore, plasmac must be the single point of truth for all cut settings so the gcode generated by the post processor MUST use the plasmac feedrate. If its not done that way, there is a high risk of stuff ups if the data in the 2 systems gets out of step. Thats why the team made you come up with the current solution you now have

Whilst its possible to insert code snippets altering the feedrate into sheetcam for hole cutting etc, I was hoping we could avoid altering the feedrate in these snippets and set the adaptive feed pin with M68 instead. That way, there is no need to use anything from sheetcam. Often, the THC is disabled when this is done, but I don't see that is necessary because of the cornerlock feature in sheetcam will do this for us.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

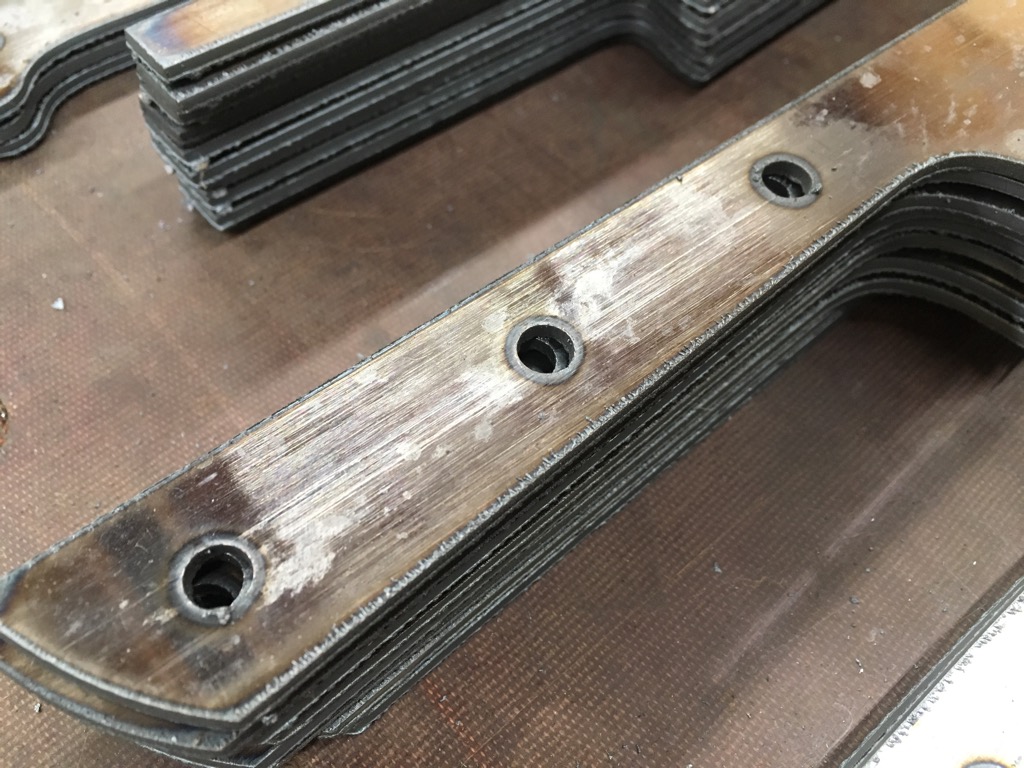

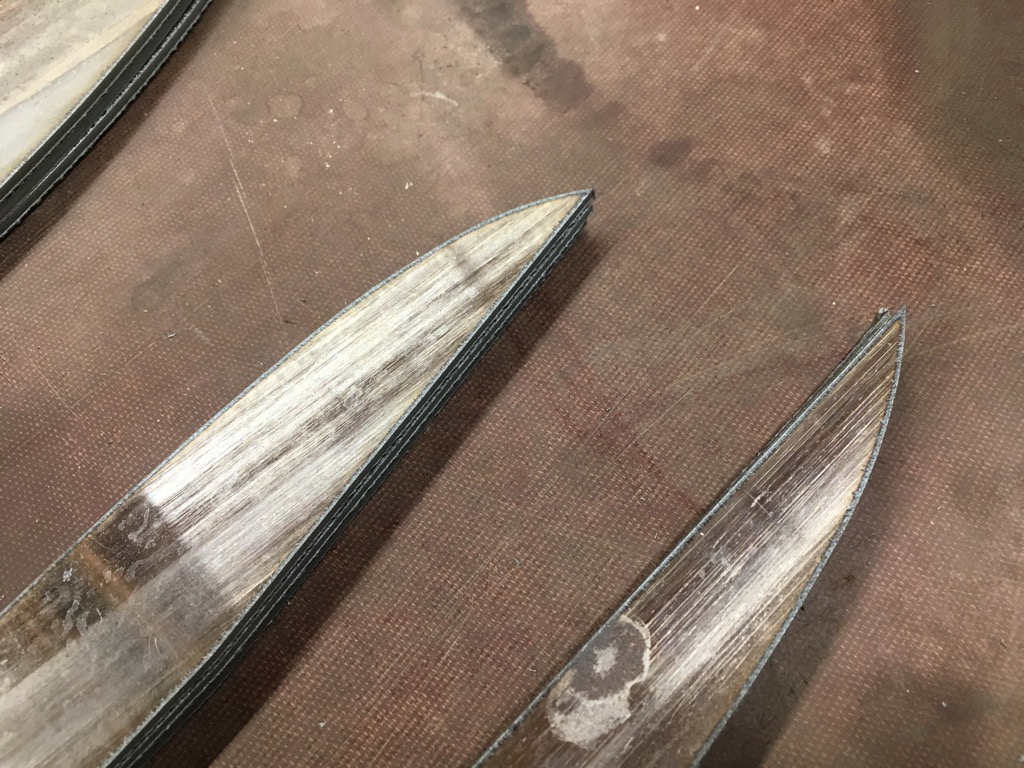

why is sheetcam posting 3 diffrent feed rates. I would think we would only need the one feedrate that gets updated from plasmac. The fixed feedrates that sheetcam puts in there where messing me up. Especially the F3.937 as it was moving so slow that the arc voltage would shoot way high and then then torch would dive into the table when it hit the F100.0

My thought is plasmac should set the feedrates and if the machine can’t do that feedrates it set then corner locking is on. It’s kinda frustrating having to have a feed rate in the gcode that matches the feed rate set in plasmac in order for corner locking to work. Being new to this I’m still veryhands on and adjusting voltage/speed on the fly to find what I really like.

Last night I was cutting these and had to enable M1 so I could switch THC off when it did the small holes. It would be nice if I could just have a tool for these holes that had the THC disabled.

Is there a readme on how I set up my tool file?

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

The reason you are getting extraneous F blocks is because your Sheetcam tool table and the Plasmac materials table are not the same. Rod's PP will work if they use the same values for feed rate. I suggest for the mean time you make sure your Plasmac materials tables are correct and match your Sheetcam tools, do not make one for every material under the sun yet only what you need for a particular job. I have used the fall back of inserting a M1 to pause the program so I can check parameters or manually change tools/settings many times.

Guys

A suggestion here. For new users CNC plasma is a steep hill to climb especially when you combine it with using a CAM program that does not have a minimal post processor for the Plasmac branch. The PP that Rod has posted as well as the one I use are adaptations of the CommandCNC post that is "overly complex" as stated by the Sheetcam author. What is needed is a simple PP with no extra features that new users have at least some hope of using with minimal effort. Most new users just want a working plasma cutter and don't care how Linuxcnc or Sheetcam work.

I may start on a really stripped down PP if I get some time.

John

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

- Posts: 757

- Thank you received: 216

John

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 20992

- Thank you received: 7158

I am sure that F3.nnn should not be there, but I do not use sheetcam so I can not help much. I do think that sheetcam is the best CAM for the money, hands down. I know people who did pay way more money for CAM that was utterly useless.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 243

- Thank you received: 32

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 20992

- Thank you received: 7158

Please Log in or Create an account to join the conversation.