Post Processor for LinuxCNC and PlasmaC

- thefabricator03

-

- Visitor

-

05 Jun 2019 22:49 - 05 Jun 2019 22:49 #135979

by thefabricator03

Do you really think that it is possible to incorporate a CAM program that has the features of sheetcam in linuxcnc? I would think such a program would be a major undertaking. Sheetcam has a lot of really handy features, like nesting and rotation of complex parts,

For the work I do I really need these features, It is all well and good for a hobbyist to be able to load a single part and cut it but when your talking a full 3000x1500 sheet you need complex nesting features and easy ability to set the correct tools for each part.

I would think it is possible but not without a lot of effort, Considering how long it has taken Linuxcnc to get serious about plasma cutting (mostly thanks to Phill) I do not see that happening for a long time.

Replied by thefabricator03 on topic Post Processor for LinuxCNC and PlasmaC

For the future of Linuxcnc plasma we need a automated dxf layer based strategy, just like the code snippets provided in sheetcam.

Every layer has a option for speed or kerf or power etc.

And we need cam program's to provide a command line input option for linux system command. That will improve the power a lot.

Imagine that you don't have to start up a cam program. All system input's are done by linuxcnc. Output is direct ngc code.

This can be called a universal program standard without actually displaying the specific program, it run's in background. Only providing the code we want to achieve.

So manybe i have a different look at the future of cam related program's. This idea has evolved trough experience with linuxcnc.

The fear point of Cam provider's is the GPL2 licence. Draftsight 2019 update is very good, and non free for windows users, why?

It's only because Freecad become's more and more powerfull. Autodesk is afraid to loose the dominant position (microsoft position) trouhh very good open source cad program's. In the end everything will be open source. But we need to fear the GPL3 licences.

www.gnu.org/licenses/gpl-3.0.nl.html

en.wikipedia.org/wiki/Ubuntu

So we can distribute linuxcnc with Ubuntu wihout any problem or with LinuxMint, also a open source distribution.

Do you really think that it is possible to incorporate a CAM program that has the features of sheetcam in linuxcnc? I would think such a program would be a major undertaking. Sheetcam has a lot of really handy features, like nesting and rotation of complex parts,

For the work I do I really need these features, It is all well and good for a hobbyist to be able to load a single part and cut it but when your talking a full 3000x1500 sheet you need complex nesting features and easy ability to set the correct tools for each part.

I would think it is possible but not without a lot of effort, Considering how long it has taken Linuxcnc to get serious about plasma cutting (mostly thanks to Phill) I do not see that happening for a long time.

Last edit: 05 Jun 2019 22:49 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7288

06 Jun 2019 00:02 #135988

by tommylight

Replied by tommylight on topic Post Processor for LinuxCNC and PlasmaC

@Rod,

When you mention different materials and nozzles and shields etc, you can add cutting with air or oxygen and nitrogen. That will add another set of tables! Oxygen here is way to expensive so I know only one person who uses it to cut 20mm plates, several other machines I retrofitted have that capability but do not use it as usually they cut thinner than 12mm.

BTW, 3001 post!

Remember when I was trying to get myself to write as I really did not like writing? I guest I am over it!

When you mention different materials and nozzles and shields etc, you can add cutting with air or oxygen and nitrogen. That will add another set of tables! Oxygen here is way to expensive so I know only one person who uses it to cut 20mm plates, several other machines I retrofitted have that capability but do not use it as usually they cut thinner than 12mm.

BTW, 3001 post!

Remember when I was trying to get myself to write as I really did not like writing? I guest I am over it!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

06 Jun 2019 06:07 #136011

by rodw

Not to mention machines that have separate shielding and cutting gasses plus acetylene for marking. We have one part that is cut from 32mm by high def plasma or flame cut. The flame cutters have a table 90 metres long. PLasma gives a much nice finish and they can pierce it.

And yes, I was thinking your English has improved out of sight over the last couple of years! We Aussies have been spoilt until recent years as we were so far from anywhere, we only spoke English but the world has shrunk!

Replied by rodw on topic Post Processor for LinuxCNC and PlasmaC

@Rod,

When you mention different materials and nozzles and shields etc, you can add cutting with air or oxygen and nitrogen. That will add another set of tables! Oxygen here is way to expensive so I know only one person who uses it to cut 20mm plates, several other machines I retrofitted have that capability but do not use it as usually they cut thinner than 12mm.

BTW, 3001 post!

Remember when I was trying to get myself to write as I really did not like writing? I guest I am over it!

Not to mention machines that have separate shielding and cutting gasses plus acetylene for marking. We have one part that is cut from 32mm by high def plasma or flame cut. The flame cutters have a table 90 metres long. PLasma gives a much nice finish and they can pierce it.

And yes, I was thinking your English has improved out of sight over the last couple of years! We Aussies have been spoilt until recent years as we were so far from anywhere, we only spoke English but the world has shrunk!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

09 Jun 2019 00:52 #136324

by rodw

Replied by rodw on topic Post Processor for LinuxCNC and PlasmaC

Its great to see that the reverse run feature is now in master branch per this thread

forum.linuxcnc.org/38-general-linuxcnc-q...uxcnc-plasmac-github

So from a post processor point of view, it seems I need to add an M52 in here somewhere.

Could somebody let me know exactly what code is required to enable reverse run from gcode?

forum.linuxcnc.org/38-general-linuxcnc-q...uxcnc-plasmac-github

So from a post processor point of view, it seems I need to add an M52 in here somewhere.

Could somebody let me know exactly what code is required to enable reverse run from gcode?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

09 Jun 2019 00:53 - 09 Jun 2019 00:54 #136325

by phillc54

Replied by phillc54 on topic Post Processor for LinuxCNC and PlasmaC

Rod,

It should already be in your startup code, metric_startup.ngc

Cheers, Phill.

It should already be in your startup code, metric_startup.ngc

M52 P1Cheers, Phill.

Last edit: 09 Jun 2019 00:54 by phillc54.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7288

09 Jun 2019 23:01 #136418

by tommylight

Replied by tommylight on topic Post Processor for LinuxCNC and PlasmaC

I think I posted in another thread thinking it was this one......

Leme try to find out what did I mess up!

Leme try to find out what did I mess up!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7288

09 Jun 2019 23:49 #136427

by tommylight

Replied by tommylight on topic Post Processor for LinuxCNC and PlasmaC

Moved from the wrong thread, my bad.

Finally nobody can say Linuxcnc does not do plasma cutting! Now there are two different types of fully automatic plasma control with integrated THC thanks to Mesa and PCW, both done in Linuxcnc but with two different approaches .

Now I need to check if plasmaC works with output from Inkscape directly, I know it did but after all the modifications somewhere I lost track. I always modify the gcode tools to output gcode without Z values and with the usual feed rate of 2000mm/minute, so I will have to check if I need any other modification to it. That is a must as all my clients use it.

If life does not get in the way as it usually does, I will change the torch and the cable on an Iskra plasma cutter I have @50A, make the earlier mentioned machine holder ( new machine torches from Trafimet in Italy, costing 190 euro a piece so I got 2 ), and finally wire the THCAD as it is still on a desk in my bedroom! Luckily plenty of Mesa cards to play with so a lot of testing is in order. Also the weather has improved last two days, it was miserable or "england weather". Sorry Andy an other UK residents, but I like summer, a lot.

FYI, was busy lately besides other things with sorting and testing roughly 150 Li-Ion batteries salvaged from laptops ( owned computer shops several years back ), and building battery packs with BMS ( battery management system ) and then testing said BMS's in preparation of finally modifying a Kawasaki GPZ600 to all electric. Need to find a decent motor or make one from an old car alternator and also build the required electronic for it.

Finally nobody can say Linuxcnc does not do plasma cutting! Now there are two different types of fully automatic plasma control with integrated THC thanks to Mesa and PCW, both done in Linuxcnc but with two different approaches .

Now I need to check if plasmaC works with output from Inkscape directly, I know it did but after all the modifications somewhere I lost track. I always modify the gcode tools to output gcode without Z values and with the usual feed rate of 2000mm/minute, so I will have to check if I need any other modification to it. That is a must as all my clients use it.

If life does not get in the way as it usually does, I will change the torch and the cable on an Iskra plasma cutter I have @50A, make the earlier mentioned machine holder ( new machine torches from Trafimet in Italy, costing 190 euro a piece so I got 2 ), and finally wire the THCAD as it is still on a desk in my bedroom! Luckily plenty of Mesa cards to play with so a lot of testing is in order. Also the weather has improved last two days, it was miserable or "england weather". Sorry Andy an other UK residents, but I like summer, a lot.

FYI, was busy lately besides other things with sorting and testing roughly 150 Li-Ion batteries salvaged from laptops ( owned computer shops several years back ), and building battery packs with BMS ( battery management system ) and then testing said BMS's in preparation of finally modifying a Kawasaki GPZ600 to all electric. Need to find a decent motor or make one from an old car alternator and also build the required electronic for it.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

10 Jun 2019 08:29 #136449

by JTknives

Replied by JTknives on topic Post Processor for LinuxCNC and PlasmaC

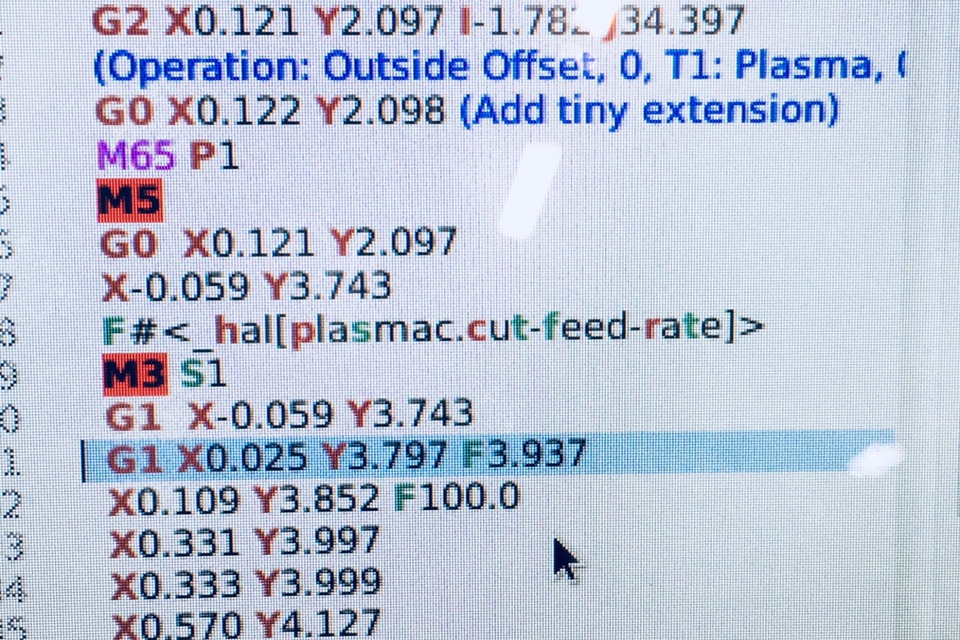

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

10 Jun 2019 08:47 #136451

by rodw

Replied by rodw on topic Post Processor for LinuxCNC and PlasmaC

Thats actually expected behaviour as its retrieving the feed rate defined in Plasmac.

Its a bit different for you because you don't have cut charts but if you had some already set up in sheetcam, Phill provided a materialverter script that will export the sheetcam tools to plasmac format.

All you have to do is make sure the plasmac and sheetcam tool numbers agree and keep the settings in plasmac.

Also, create a tool called "CENTERPUNCH". Then if you have holes you just want to mark hole centres for subsequent drilling, you can create a new layer in sheetcam and move your holes to that layer. Then do a drill operation with the centerpunch tool on that layer and it will spot them for you. It is pretty cool watching plasmac swap the tools and updating the GUI on auto pilot!

Its a bit different for you because you don't have cut charts but if you had some already set up in sheetcam, Phill provided a materialverter script that will export the sheetcam tools to plasmac format.

All you have to do is make sure the plasmac and sheetcam tool numbers agree and keep the settings in plasmac.

Also, create a tool called "CENTERPUNCH". Then if you have holes you just want to mark hole centres for subsequent drilling, you can create a new layer in sheetcam and move your holes to that layer. Then do a drill operation with the centerpunch tool on that layer and it will spot them for you. It is pretty cool watching plasmac swap the tools and updating the GUI on auto pilot!

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

10 Jun 2019 10:54 - 10 Jun 2019 10:56 #136454

by phillc54

Replied by phillc54 on topic Post Processor for LinuxCNC and PlasmaC

If you define a F word like the F 3.937 then linuxcnc will use that as the feed rate. I don't think they should be there.

Cheers, Phill.

Cheers, Phill.

Last edit: 10 Jun 2019 10:56 by phillc54.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.291 seconds