PlasmaC Fiber laser 1Kw head height control + auto focuas

- Becksvill

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 96

03 Aug 2020 22:14 #177115

by Becksvill

Replied by Becksvill on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

taloot

I just read the data sheet on that plasma cutter www.jscut.cn/product/205_374

and it looked like it can cut 50mm plate. that is awesome. have you actually tried that thickness?

I think i really need to get into this

I just read the data sheet on that plasma cutter www.jscut.cn/product/205_374

and it looked like it can cut 50mm plate. that is awesome. have you actually tried that thickness?

I think i really need to get into this

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

04 Aug 2020 16:57 #177261

by taloot

i do have video for actual cutting

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

taloot

I just read the data sheet on that plasma cutter www.jscut.cn/product/205_374

and it looked like it can cut 50mm plate. that is awesome. have you actually tried that thickness?

I think i really need to get into this

i do have video for actual cutting

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

05 Aug 2020 17:23 - 05 Aug 2020 17:44 #177410

by taloot

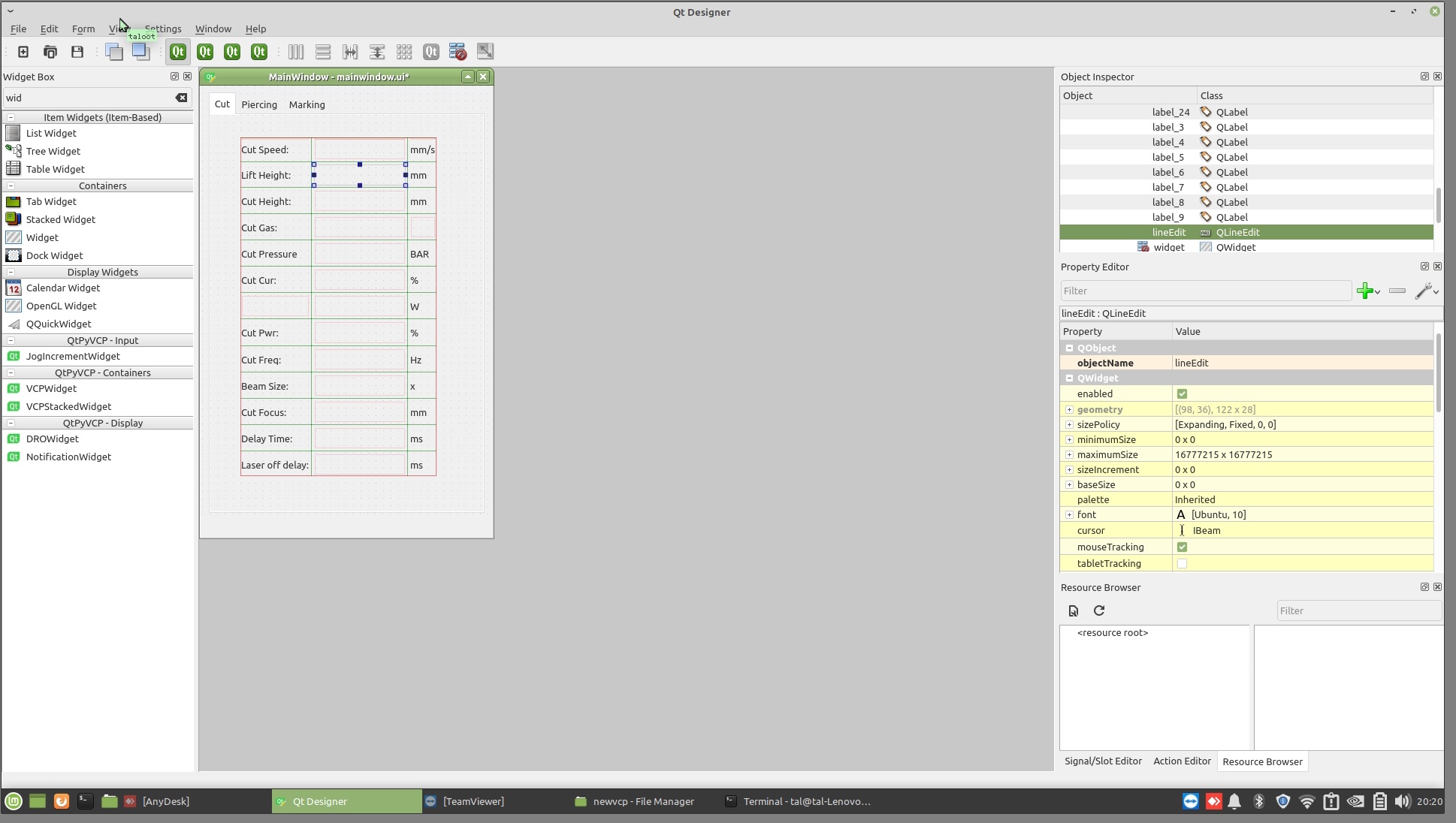

this is 3 main tabs

i will add monitoring for gas too

any tips will be appreciated

almost i fixed gas and laser operation

but i still have 1 problem need to be solved the best way.

the capacitance need to be calibrated at about 3 mm away from metal

and i want to probe directly to pricing height.

is it better for me to make new THC + ohmic component?

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

this is 3 main tabs

i will add monitoring for gas too

any tips will be appreciated

almost i fixed gas and laser operation

but i still have 1 problem need to be solved the best way.

the capacitance need to be calibrated at about 3 mm away from metal

and i want to probe directly to pricing height.

is it better for me to make new THC + ohmic component?

Last edit: 05 Aug 2020 17:44 by taloot.

The following user(s) said Thank You: Becksvill

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Aug 2020 03:28 #177462

by phillc54

You could set the pierce height to 0.01 (it wont accept 0) and factor that out with the ohmic probe offset (it will take negative values) in the config panel. If cut height is the same as pierce height then set it to 0.01 as well.

Replied by phillc54 on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

If I understand you want to probe down and when it is 3mm above the material you want it to stop and that will be the pierce height. I assume the capacitive probe will tell you that it is 3mm away.but i still have 1 problem need to be solved the best way.

the capacitance need to be calibrated at about 3 mm away from metal

and i want to probe directly to pricing height.

You could set the pierce height to 0.01 (it wont accept 0) and factor that out with the ohmic probe offset (it will take negative values) in the config panel. If cut height is the same as pierce height then set it to 0.01 as well.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

06 Aug 2020 07:52 - 06 Aug 2020 08:01 #177477

by taloot

so the probe pin should go high @ the pierce height

if

pierce is 3mm it will be 0.01

cut is 1mm so it will be -2.01

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

If I understand you want to probe down and when it is 3mm above the material you want it to stop and that will be the pierce height. I assume the capacitive probe will tell you that it is 3mm away.but i still have 1 problem need to be solved the best way.

the capacitance need to be calibrated at about 3 mm away from metal

and i want to probe directly to pricing height.

You could set the pierce height to 0.01 (it wont accept 0) and factor that out with the ohmic probe offset (it will take negative values) in the config panel. If cut height is the same as pierce height then set it to 0.01 as well.

so the probe pin should go high @ the pierce height

if

pierce is 3mm it will be 0.01

cut is 1mm so it will be -2.01

Last edit: 06 Aug 2020 08:01 by taloot.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Aug 2020 12:13 #177500

by phillc54

Replied by phillc54 on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

Sorry, I confused myself here.

If you use the ohmic input and your capacitive sensor senses the material at 3.5mm above the material then you would set the ohmic offset to -3.5, then you set the pierce height and cut height to what they should be.

There is one issue that I have just discovered. After PlasmaC senses the ohmic input it sends the torch to zero height which would touch the torch against the material. There is no need for it to do that so I will take a look at it tomorrow.

If you use the ohmic input and your capacitive sensor senses the material at 3.5mm above the material then you would set the ohmic offset to -3.5, then you set the pierce height and cut height to what they should be.

There is one issue that I have just discovered. After PlasmaC senses the ohmic input it sends the torch to zero height which would touch the torch against the material. There is no need for it to do that so I will take a look at it tomorrow.

The following user(s) said Thank You: taloot

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

06 Aug 2020 21:40 #177553

by tommylight

Replied by tommylight on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

How much does a 1KW laser with power supply and head and whatever goes with that cost?

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

06 Aug 2020 21:46 - 06 Aug 2020 21:49 #177556

by taloot

main part you need

1 laser source price range 5000-7000 usd depends on the brand

2 lase head start from 450 - 1000 depends on brand and power rating also manual or auto foucus

3 chiller 750 usd

there no power supply its build in unlike co2

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

How much does a 1KW laser with power supply and head and whatever goes with that cost?

main part you need

1 laser source price range 5000-7000 usd depends on the brand

2 lase head start from 450 - 1000 depends on brand and power rating also manual or auto foucus

3 chiller 750 usd

there no power supply its build in unlike co2

Last edit: 06 Aug 2020 21:49 by taloot.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

06 Aug 2020 22:07 #177558

by tommylight

Replied by tommylight on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

@taloot

Thank you.

Not bad at all, and since you mentioned earlier the power usage i got even more interested in this.

I am used to old type laser cutters that need 45KW of power for a 3KW laser.

Thank you.

Not bad at all, and since you mentioned earlier the power usage i got even more interested in this.

I am used to old type laser cutters that need 45KW of power for a 3KW laser.

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

07 Aug 2020 00:25 #177562

by taloot

that was yag laser i guess with xenon lamp.. very bad technology

keep in mind u can pay 1000 usd and buy laser welding gun,,, u can use the laser source for weld and for cut

also there is 2 type one with feeder wire .. other not,, just diffused 2 sheet together,

Replied by taloot on topic PlasmaC modification to fit fiber laser rs485 control head capacitance Autofou

@taloot

Thank you.

Not bad at all, and since you mentioned earlier the power usage i got even more interested in this.

I am used to old type laser cutters that need 45KW of power for a 3KW laser.

that was yag laser i guess with xenon lamp.. very bad technology

keep in mind u can pay 1000 usd and buy laser welding gun,,, u can use the laser source for weld and for cut

also there is 2 type one with feeder wire .. other not,, just diffused 2 sheet together,

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.295 seconds