PlasmaC Fiber laser 1Kw head height control + auto focuas

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

This issue is now fixed.There is one issue that I have just discovered. After PlasmaC senses the ohmic input it sends the torch to zero height which would touch the torch against the material. There is no need for it to do that so I will take a look at it tomorrow.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

This issue is now fixed.There is one issue that I have just discovered. After PlasmaC senses the ohmic input it sends the torch to zero height which would touch the torch against the material. There is no need for it to do that so I will take a look at it tomorrow.

which version is fixed?

do i have to build from source?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

now i done making the Qtpyvcp...2.8 and master. I see the 2.8 buildbot (stretch and buster) is up to date but master isn't yet. You can also build from source

i have input and output pin for that widget

where can i hook this pins? and what to link and unlink....

widget have input from plasmac and based on this the process done and send back

just im too bad manipulating the HAL

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

#***** plasmac component ***********************************************

net plasmac:axis-max-limit ini.z.max_limit => plasmac.axis-z-max-limit

net plasmac:axis-min-limit ini.z.min_limit => plasmac.axis-z-min-limit

#***** run page ********************************************************

# outputs

net plasmac:cornerlock-enable plasmac_run.cornerlock-enable => plasmac.cornerlock-enable

net plasmac:cut-feed-rate plasmac_run.cut-feed-rate-f => plasmac.cut-feed-rate

net plasmac:cut-height plasmac_run.cut-height-f => plasmac.cut-height

net plasmac:cut-volts plasmac_run.cut-volts-f => plasmac.cut-volts

net plasmac:kerfcross-enable plasmac_run.kerfcross-enable => plasmac.kerfcross-enable

net plasmac:mesh-enable-0 plasmac_run.mesh-enable => plasmac.mesh-enable-0

net plasmac:mesh-ignore-ok plasmac_run.mesh-ignore-ok => plasmac.mesh-ignore-ok

net plasmac:ohmic-probe-enable plasmac_run.ohmic-probe-enable => plasmac.ohmic-probe-enable

net plasmac:pause-at-end plasmac_run.pause-at-end-f => plasmac.pause-at-end

net plasmac:pierce-delay plasmac_run.pierce-delay-f => plasmac.pierce-delay

net plasmac:pierce-height plasmac_run.pierce-height-f => plasmac.pierce-height

net plasmac:puddle-jump-delay plasmac_run.puddle-jump-delay-f => plasmac.puddle-jump-delay

net plasmac:puddle-jump-height plasmac_run.puddle-jump-height-f => plasmac.puddle-jump-height

net plasmac:thc-enable plasmac_run.thc-enable-out => plasmac.thc-enable

net plasmac:use-auto-volts plasmac_run.use-auto-volts => plasmac.use-auto-voltsany plasmac_run.pins not listed above are manipulated directly by the code in plasmac_run.py

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

Any Run Panel pins that are linked in HAL are done in plasmac_run.hal

Warning: Spoiler!#***** plasmac component *********************************************** net plasmac:axis-max-limit ini.z.max_limit => plasmac.axis-z-max-limit net plasmac:axis-min-limit ini.z.min_limit => plasmac.axis-z-min-limit #***** run page ******************************************************** # outputs net plasmac:cornerlock-enable plasmac_run.cornerlock-enable => plasmac.cornerlock-enable net plasmac:cut-feed-rate plasmac_run.cut-feed-rate-f => plasmac.cut-feed-rate net plasmac:cut-height plasmac_run.cut-height-f => plasmac.cut-height net plasmac:cut-volts plasmac_run.cut-volts-f => plasmac.cut-volts net plasmac:kerfcross-enable plasmac_run.kerfcross-enable => plasmac.kerfcross-enable net plasmac:mesh-enable-0 plasmac_run.mesh-enable => plasmac.mesh-enable-0 net plasmac:mesh-ignore-ok plasmac_run.mesh-ignore-ok => plasmac.mesh-ignore-ok net plasmac:ohmic-probe-enable plasmac_run.ohmic-probe-enable => plasmac.ohmic-probe-enable net plasmac:pause-at-end plasmac_run.pause-at-end-f => plasmac.pause-at-end net plasmac:pierce-delay plasmac_run.pierce-delay-f => plasmac.pierce-delay net plasmac:pierce-height plasmac_run.pierce-height-f => plasmac.pierce-height net plasmac:puddle-jump-delay plasmac_run.puddle-jump-delay-f => plasmac.puddle-jump-delay net plasmac:puddle-jump-height plasmac_run.puddle-jump-height-f => plasmac.puddle-jump-height net plasmac:thc-enable plasmac_run.thc-enable-out => plasmac.thc-enable net plasmac:use-auto-volts plasmac_run.use-auto-volts => plasmac.use-auto-volts

any plasmac_run.pins not listed above are manipulated directly by the code in plasmac_run.py

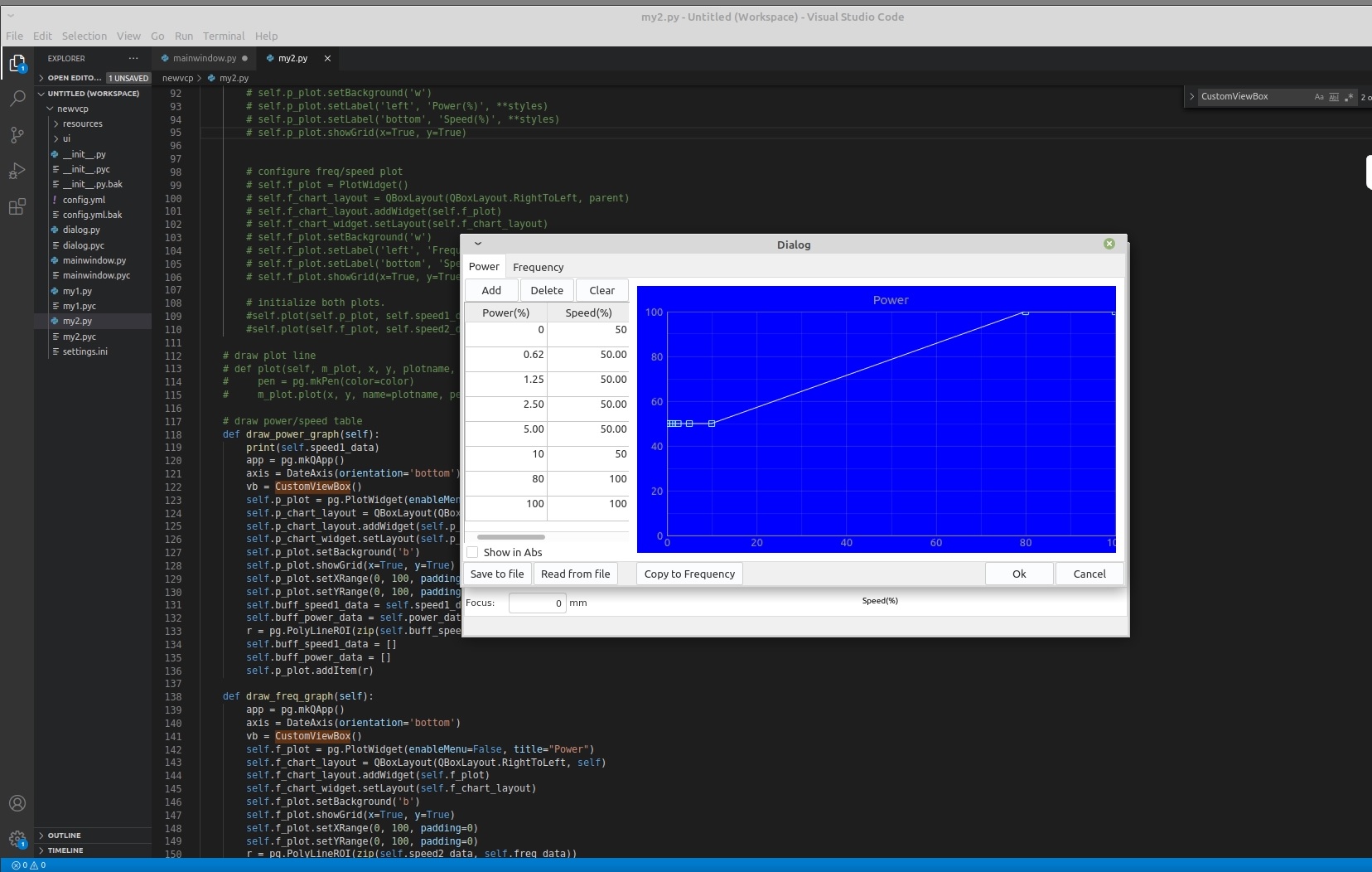

okey i have done

1 capacitance sensor to replace the THCAD

2 laser comm using rs232 similar as ur python script

3 gas control console monitor and control (qtpyvcp)

4 independent laser setting while cut or while mark or pierce (qtpyvcp)

5 dynamic power curve ( speed vs laser power or PWM freq)

6 focus setting

Attachments:

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

i will use 2 pwm to analog convertor (0-10v)

1 for laser

2 for gas valve

is it to linked to spindle control?

if yes can i load 2 spindles?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21357

- Thank you received: 7286

Adding a resistor and a small capacitor to the PWM output will make it analogue, but only up to 5V if the PWM output is 5V.another small issue

i will use 2 pwm to analog convertor (0-10v)

1 for laser

2 for gas valve

is it to linked to spindle control?

if yes can i load 2 spindles?

Since you are using Mesa boards, you can use normal outputs for PWM but with very limited frequency, so if the frequency is not high the above idea might be useful.

That makes 3 PWM's !

It can be controlled as a spindle but it does not have to be, PWM's can be set on their own.And yes, you can have up to 8 spindles if i remember correctly in LinuxCNC 2.8 and Master.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

- Posts: 175

- Thank you received: 88

Adding a resistor and a small capacitor to the PWM output will make it analogue, but only up to 5V if the PWM output is 5V.another small issue

i will use 2 pwm to analog convertor (0-10v)

1 for laser

2 for gas valve

is it to linked to spindle control?

if yes can i load 2 spindles?

Since you are using Mesa boards, you can use normal outputs for PWM but with very limited frequency, so if the frequency is not high the above idea might be useful.

That makes 3 PWM's !

It can be controlled as a spindle but it does not have to be, PWM's can be set on their own.And yes, you can have up to 8 spindles if i remember correctly in LinuxCNC 2.8 and Master.

you are following right

exactly 3 pwm generator

2 for the metioned above

and 1 for laser it self.. (24v PWM)

can i use PWMgen instead? if so can i see example?

a lot of options,, but they are important for mirror finish cutting

i will buy ready made convertor, but how can i link it inside hal file

do i have to load pwmgen,, for each function

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21357

- Thank you received: 7286

forum.linuxcnc.org/10-advanced-configura...-superimposing-a-pic

There is also the complete config there, but here is the important part:

loadrt pwmgen output_type=0

addf pwmgen.make-pulses base-thread

addf pwmgen.update servo-thread

setp pwmgen.0.enable TRUE

#setp pwmgen.0.pwm-freq 1000

#setp pwmgen.0.scale 100

#setp pwmgen.0.offset 0

#setp pwmgen.0.min-dc 1

#setp pwmgen.0.max-dc 99

#setp pwmgen.0.dither-pwm true

net analogout motion.analog-out-00 => pwmgen.0.value

net laserpwm pwmgen.0.pwm => parport.0.pin-02-outlinuxcnc.org/docs/2.4/html/hal_rtcomps.html#sec:PWMgen

Please Log in or Create an account to join the conversation.