Sheetcam revised post - please test

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

Magic comment/g-code command, to me they are the same, # commands get called magic comments in the docs as well (even if I'm biased because I'm probably the one who put that thereIt's not the magic comment. Its the comment after setting some of the hole cutting variables.

It looks like there is a string to float conversion happening but the number AND the rest of the line is being parsed causing an error

I understand what the entire issue is. A current "work around" is to put the comment the line before the magic comment/g-code command while any necessary change gets evaluated.

I think I will leave the post processor as it is now as Les has copied it for inclusion in his next release. In any case, the sheetcam report provides the data you are looking for at the part level.

Half way there I reckon. Honestly, I don't intend to pick up Les' post until, at a minimum, it does the stuff the original post did.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

Butt not yet using the RS485 connections

I am using the original F post

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

Magic comment/g-code command, to me they are the same, # commands get called magic comments in the docs as well (even if I'm biased because I'm probably the one who put that thereIt's not the magic comment. Its the comment after setting some of the hole cutting variables.

).

Not even close. When you use

#<h_velocity> = nnYou are using a gcode named parameter.

ref: linuxcnc.org/docs/devel/html/gcode/overv...ml#_named_parameters

It would not be unreasonable to expect the filter correctly processes valid gcode. Its a bug!

You can use whatever post processor you like or you can write your own which I did in the beginning. I think Phil removed links to the one he wrote so getting a full featured post processor distributed with sheetcam is worthwhile.

It would be interesting to extend the post to change the velocity slow down based on the hole/arc diameter as some of the sheetcam rule sets in use do. But I just wanted to implement the plasmac default features.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

I don't think there is any functional difference between the Sheetcam post and the one you are using. There are two main differences I can think of:What is the recommended post for QTplasmaC using hypertherm 65 using the tools table from them.

Butt not yet using the RS485 connections

I am using the original F post

1. The Sheetcam one more closely follows the Sheetcam paradigm. Spotting is moved to drilling operations so there is no need to use a specific Centre Spot tool for it. This was a carry over from a CandCNC post I modelled my original work on.

2. By default, Sheetcam passes all of the cut parameters to Plasmac using a magic comment so Sheetcam is the master of all cutting parameters to avoid data redundancy and the need to sync sheetcam to Plasmac if you make a change. Changing a variable in the Sheetcam Post makes it retrieve the Plasmac material based on the tool number the same as what you have now.

3. the Sheetcam post is part of sheetcam! The previous post was really unofficial as it was on the forum here, not part of the Linuxcnc distro. To me this is the correct model.

I personally think 2. is a big positive issue, you only should have data stored in one place to avoid it getting out of step.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

You are using a gcode named parameter.

ok

Its a bug!

Yes, I'm still aware.

What I said:

I understand what the entire issue is. A current "work around" is to put the comment the line before the magic comment/g-code command while any necessary change gets evaluated.

I am; thanks.You can use whatever post processor you like

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

The default is to have #<holes>=0. By setting the default to 2 you are forcing all users who update to either edit the PP or change the way they currently do holes in SheetCam. An update should not force users to make unnessary changes.

It would be interesting to extend the post to change the velocity slow down based on the hole/arc diameter as some of the sheetcam rule sets in use do. But I just wanted to implement the plasmac default features.

The automatic holes feature was really designed for users that code by hand or for users of simplistic gcode PPs like Inkskape.

Personally I wouln't use the QtPlasmaC holes feature from SheetCam because there is much more flexibility by doing it in SheetCam itself.

The early versions of the holes feature had four or five different hole sizes but that was removed to align with the above.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

I got as far as reading the Lua docs about arrays this morning but have not looked at the Sheetcam onArc method to see if its feasible. I think it is.

I have not been using hole slowdowns often but recently I enabled the Plasmac defaults and it did make a difference. Long term I want to have an enhanced filter to apply more sophisticated hole adjustments. I may get there one day.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

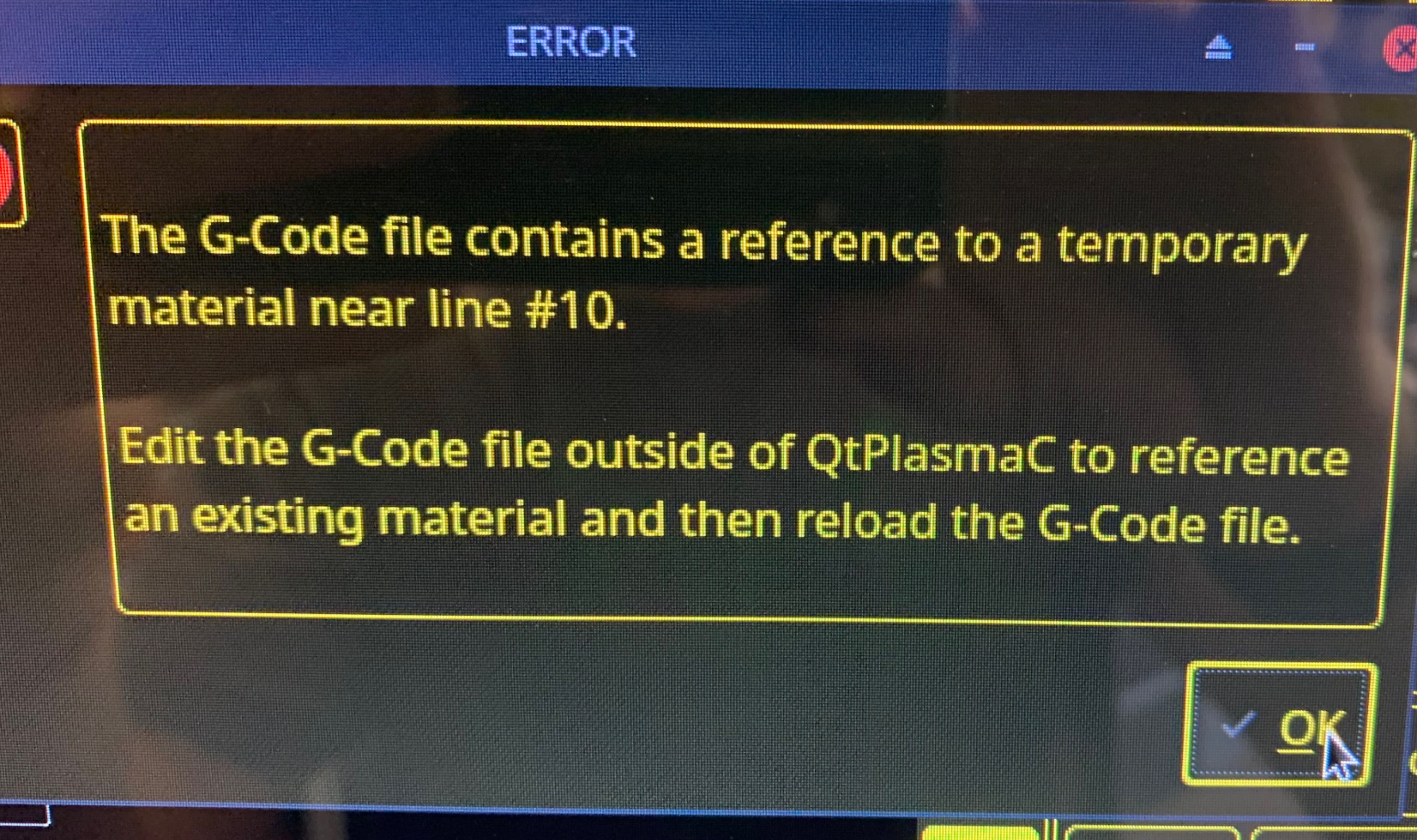

I updated to this post on the new machine running QTPlasmaC.

The only problem (re:user errors) I'm encountering is that since the rain I keep getting power outages in the shed (not asscoiated with this) and when I restart and get everything aligned again, I can only start from the beginning of the job. Previously I would be able to enter a job at the beginning of any cut.

The error I get is attached, along with the first 30 lines of gcode.

I think I may just need to get the toolset loaded into QTPlasmaC, however I am still adjusting these in sheet cam as I learn the machine anyhow it runs.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

So only workaround is to go to an old pp and choose the material in QTPlasmac?

Please Log in or Create an account to join the conversation.