Feature Request: ramp piercing (aka moving piercing)

- RDA

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 43

Kjellberg has quite a nice set of hole parameters, its nothing that special but special enough that you cant share the math to implement generation Q-holes. You can check a generic introduction here contour cut download the brochure.I had a look at the pro pierce video. It appears they are doing a back/forth slot shape. Ie small offset with arc each end a few times then stop at one end of the slot and wait, then after pierce (probably just a time period) start forward for a section of length/time at a slower speed and atill at pierce heigh,. Then transition to cut height and speed.

i note the circle cut also seems to be user high definition hole mechanics with a different speed and over burn on the last arc segment of the hole. I have cracked the system already in monokrom.

cheers - J.

The different speeds and overburn are only a part of all the different hole cutting technologies. The trickier thing is the leadin generation and interpolation between different hole sizes. But far biggest task is to actually tune in the parameters, I can assure its a shit ton of holes to cut to get the data across all different thickness and process ranges.

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

The "next step" now that I have smarter pierces available is to include that capability in the mix.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Kjellberg has quite a nice set of hole parameters, its nothing that special but special enough that you cant share the math to implement generation Q-holes.

@RDA, Its possible that Joco and I already have the maths in a working config in his monokrom controller. I was contacted by a guy who had worked for Kjellberg and others that explained in detail the normal smart hole methodology. He then called in one of his associates who wrote some demo python code for the leadins. Joco coded this as a filter that removes existing holes and replaces them with the algorithm. I described the methodology here

But as you say, there is days and days of cutting to develop the ideal cut data. But thats what the big guys doo all the time, forever tweaking their algorithms. We had some ideas about capturing user supplied data but its a good way away...

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 43

Yeah that's pretty much it. Some do it in a slightly different way but the principal is the same.

Kjellberg has quite a nice set of hole parameters, its nothing that special but special enough that you cant share the math to implement generation Q-holes.

@RDA, Its possible that Joco and I already have the maths in a working config in his monokrom controller. I was contacted by a guy who had worked for Kjellberg and others that explained in detail the normal smart hole methodology. He then called in one of his associates who wrote some demo python code for the leadins. Joco coded this as a filter that removes existing holes and replaces them with the algorithm. I described the methodology here

But as you say, there is days and days of cutting to develop the ideal cut data. But thats what the big guys doo all the time, forever tweaking their algorithms. We had some ideas about capturing user supplied data but its a good way away...

I would probably do a couple tweaks that are not in the video but its minor stuff like cut height (obviously you would want to tweak it too based on size), max pierce distance ( so set a max distance for center pierce, no need to pierce in the center if the hole is big enough that the spatter doesn't end up in the cut path.).

I would also consider have a "parameter" call out to enable the filter in specific holes. Meaning you would not have to parse through all the holes but just look for a specif code in the g-code where the filter would "activate".

Probably a stupid question but what is monokrom?

Please Log in or Create an account to join the conversation.

- caretech

-

- Offline

- Senior Member

-

- Posts: 62

- Thank you received: 23

I'm following this piercing conversation with interest. When I built my table I figured most of what I'd cut would be 1/2" or less but I'm surprised how often I've been asked to cut 1" plate. My Powermax 85 sometimes pierces 1" without problem and sometimes it struggles quite a bit. Once it is through, it cuts 1" beautifully. For now I can't afford to upgrade my plasma unit so if any improvements are made that will allow small machines to pierce thicker material, I'm all for it.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Its so long ago, I can barely remember if it always pierced in the centre but segment lengths were the key factor.

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

- Posts: 531

- Thank you received: 327

When dealing with thick materials (i.e. those that the specific machine can not just punch through with a normal pierce delay) then a longer lead in migh be desireable to allow the space for the more exotic pierce process?

Cheers - J.

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 43

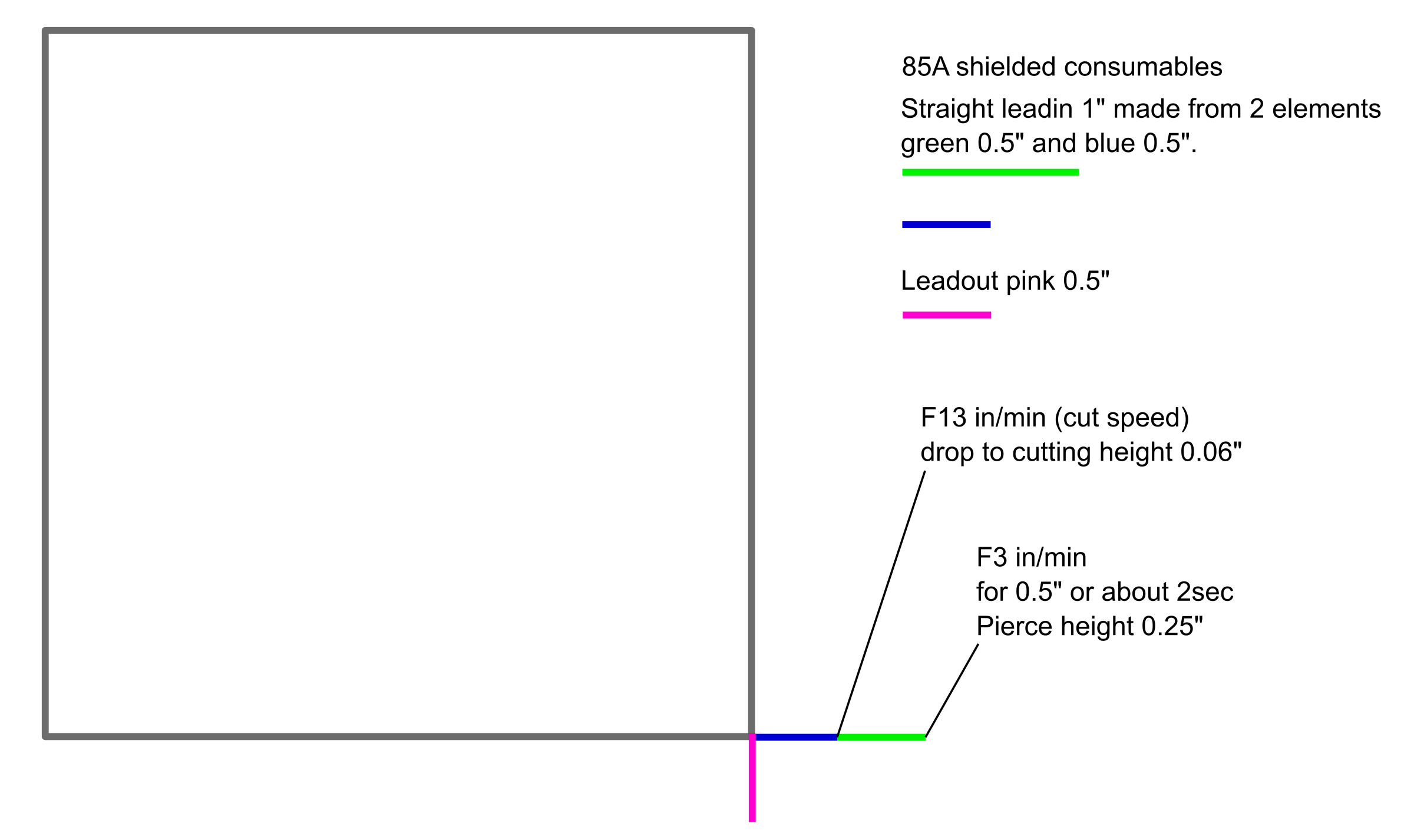

Ok so the next time you cut 1" or if you have some scrap lying around try something like in the attachment, maybe not spot on but pretty close. When you figure out the correct speed to move while piercing you can set the lengths of everything else.You can read about Monokrom here. forum.linuxcnc.org/qtpyvcp/40082-monokro...mac-and-mill?start=0

I'm following this piercing conversation with interest. When I built my table I figured most of what I'd cut would be 1/2" or less but I'm surprised how often I've been asked to cut 1" plate. My Powermax 85 sometimes pierces 1" without problem and sometimes it struggles quite a bit. Once it is through, it cuts 1" beautifully. For now I can't afford to upgrade my plasma unit so if any improvements are made that will allow small machines to pierce thicker material, I'm all for it.

Attachments:

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 43

Ok so first of all you would typically to redo all the holes. The hole data in theses systems contain parameters from the smallest to biggest. The biggest meaning you can use normal cut speed and arc voltage control. This would be applied to all holes above some diameter, so please note that most of these systems put data on all holes, not just small ones.re the centre pierce I would need to re look, I think I might have just gone with centre as it made the math a lot easier. I'm sure it could be enhanced to shift things based on hole size. The parsing also filters on hole size, so if a hole is outside the filter (bigger or smaller) then it is not processed. I think smaller might be turned into spots and larger is just left as is. Cut height is standard on the material. Unless there needs to be a special cut height for the hole, will need to check what was done re that. Given plasmac sets the cut height using a pin that could require some extension of plasmac or dynamic link/unlik of hal nets to be able to set a different cut height. Then there is how THC plays in this and when the voltage sample is taken to drive cut height. Yeah .... not straight forward, but pretty much anything is doable with enough time applied.

When dealing with thick materials (i.e. those that the specific machine can not just punch through with a normal pierce delay) then a longer lead in migh be desireable to allow the space for the more exotic pierce process?

Cheers - J.

So the center pierce, like said above you typically set data to all holes, if you have a hole that has a d 20" on a 3/8" plate, it makes absolutely no sense to pierce from the center. You already have the max size hole data (the hole that can be cut with normal speed, height and so on), so every hole size above uses that leadin, it does not extrapolate from that. Or you give a distance lets say 10*kerf, if the hole center is further than that, treat that as the starting point, or hole center. I hope you get the idea?

All holes up to the point that normal cutting speed can be used are cut with height locked.

Cut height should be adjustable based on hole size.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 11731

- Thank you received: 3973

Please Log in or Create an account to join the conversation.