MonoKrom - QtPyVCP GUI for PlasmaC and Mill

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

27 Nov 2021 00:05 #227714

by Joco

Replied by Joco on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

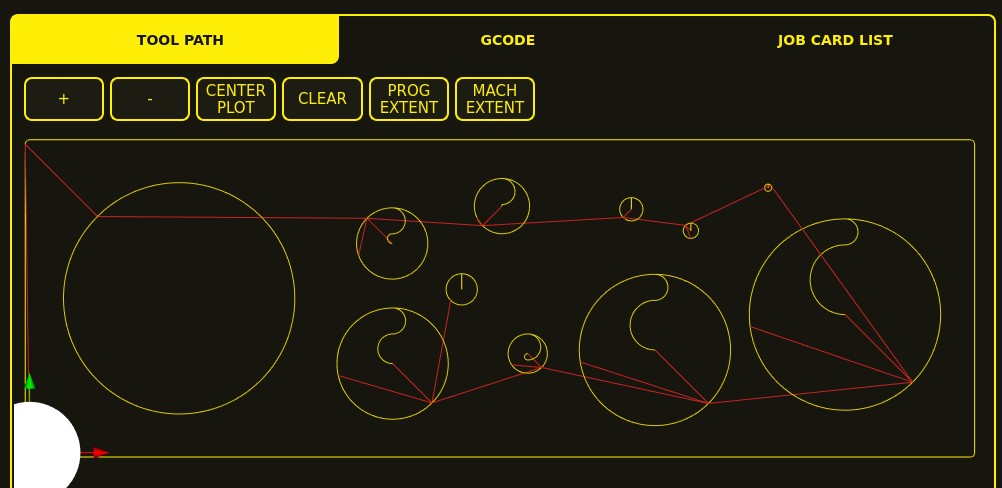

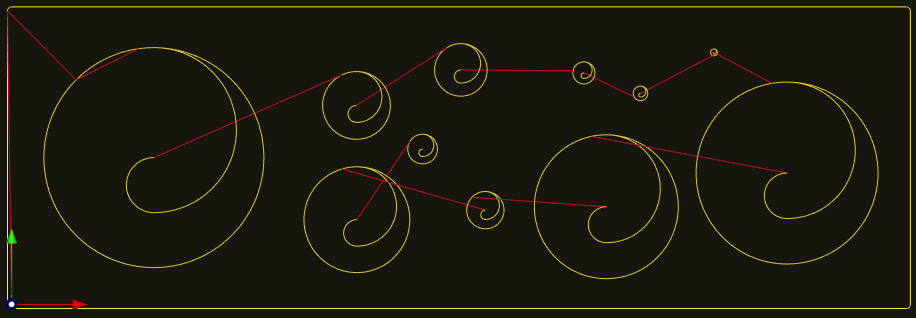

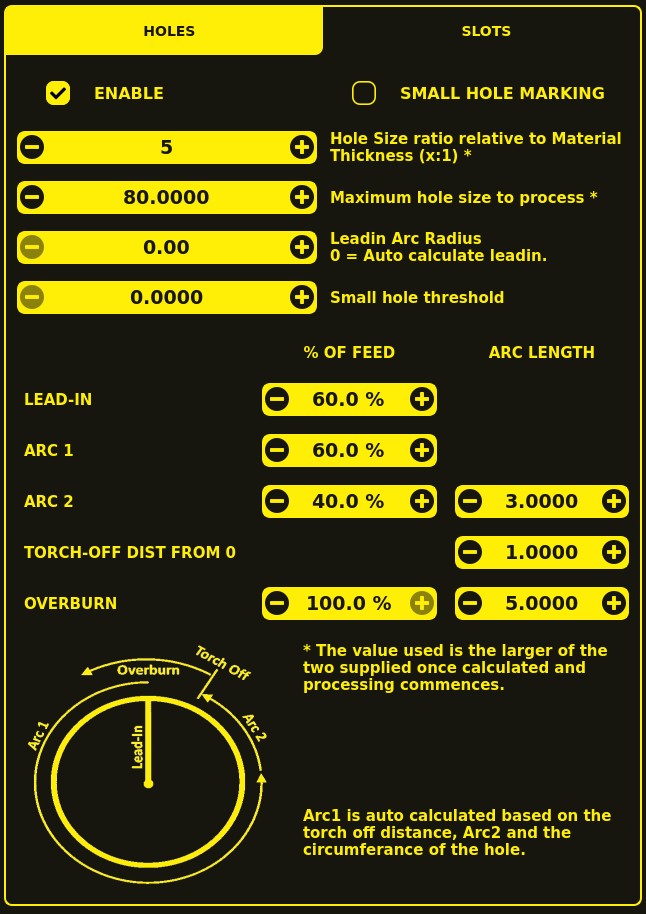

With some significant help from Rod and feedback from others I have been working through not just hole detection but also automatic generation of leadins based on common practice from the "big boys" (hypertherm, thermal dynamics etc etc etc). The gcode under the hood on this is breaks the hole into arcs. Each arc in the circle can have its own cut speed and if you have the ability it could i theory have different amps and/or gas. These arcs include an overburn.

The hole finding/generation code also have some rules on what circles are considered holes and what is seen as too small to be able to do a "clever" leadin v's a straight line. There is still tuning to do but it looks to be fundamentally working.

The hole finding/generation code also have some rules on what circles are considered holes and what is seen as too small to be able to do a "clever" leadin v's a straight line. There is still tuning to do but it looks to be fundamentally working.

Attachments:

The following user(s) said Thank You: tommylight, rodw, KCJ, anfänger

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

27 Nov 2021 02:40 #227720

by rodw

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Awesome work Joco. It exciting to see such advanced features finding their way into Linuxcnc and its been a pleasure to work with you on this project.

For the benefit of other followers, this brings the so called true hole technology found in high definition (hi def) plasma cutting that is not found on air plasmas. Most of the smarts for hi def holes is done within the manufacturer's post processor (eg pronest et al). A database holds data for different size holes for each cutting chart that include a number of parameters applied by the pp as it navigates the leadin and hole circumference allowing the speed and other settings to be varied at various control points. So this means say a 10mm hole will have totally different settings to a 20mm hole on the same material.

We don't have control over people's pp as a manufacturer would. So Joco has built this database driven hole processing technology into a gcode filter that senses holes, removes the current leadin and G3/G2 code, then replaces that with custom code according to the hi def paradigm. He's been able to fully integrate the database into Linuxcnc's tool table so this has become a very sophisticated piece of plasma technology.

For the benefit of other followers, this brings the so called true hole technology found in high definition (hi def) plasma cutting that is not found on air plasmas. Most of the smarts for hi def holes is done within the manufacturer's post processor (eg pronest et al). A database holds data for different size holes for each cutting chart that include a number of parameters applied by the pp as it navigates the leadin and hole circumference allowing the speed and other settings to be varied at various control points. So this means say a 10mm hole will have totally different settings to a 20mm hole on the same material.

We don't have control over people's pp as a manufacturer would. So Joco has built this database driven hole processing technology into a gcode filter that senses holes, removes the current leadin and G3/G2 code, then replaces that with custom code according to the hi def paradigm. He's been able to fully integrate the database into Linuxcnc's tool table so this has become a very sophisticated piece of plasma technology.

The following user(s) said Thank You: tommylight, KCJ, Joco, anfänger

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

01 Dec 2021 08:29 #228098

by Joco

Replied by Joco on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Attachments:

The following user(s) said Thank You: tommylight, rodw, KCJ

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

27 Dec 2021 05:58 #230047

by Joco

Replied by Joco on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

It's finally happened. After being tinkering on this going back ~6 months with the activty increasing a alot of the last ~3mths we have FIRST CUTS of steel thanks to rodw.

Next will be refinements and bug fixing to get to a first working version. Then I think baselining that iteration and moving on to more enhancements.

Cheers - J.

Next will be refinements and bug fixing to get to a first working version. Then I think baselining that iteration and moving on to more enhancements.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

27 Dec 2021 06:12 - 27 Dec 2021 06:20 #230048

by rodw

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Yes, after all this time, the demo part in the tool above has been cut using internally generated high definition techniques applied by a gcode filter. The filter removes the hole paths and replaces them including leadin and overburn based on a paradigm that uses a database driven approach.

We still have a lot to learn about this approach but the one thing I did notice was there were no divots on the leadin and exit.

On one hole, our random guess must have been pretty close to the mark as the hole centre slowly dropped away after the torch was turned off but motion continued. This is what we want. The torch to go off just as the plug drops away.

Joco has done an amazing job to get to this stage. I've just sat on the sidelines reviewing the progress and providing feedback. As it is now, its pretty useable.

We still have a lot to learn about this approach but the one thing I did notice was there were no divots on the leadin and exit.

On one hole, our random guess must have been pretty close to the mark as the hole centre slowly dropped away after the torch was turned off but motion continued. This is what we want. The torch to go off just as the plug drops away.

Joco has done an amazing job to get to this stage. I've just sat on the sidelines reviewing the progress and providing feedback. As it is now, its pretty useable.

Attachments:

Last edit: 27 Dec 2021 06:20 by rodw.

The following user(s) said Thank You: TurBoss, KCJ

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

27 Dec 2021 21:41 #230089

by rodw

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

This video outlines the Smart hi def hole cutting features of Monokrom

The following user(s) said Thank You: tommylight, KCJ

Please Log in or Create an account to join the conversation.

- htdave

-

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 0

13 May 2022 01:40 #242842

by htdave

Replied by htdave on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11732

- Thank you received: 3973

13 May 2022 02:01 #242843

by rodw

Replied by rodw on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Dave, Its pretty close to working. I think it can be used for production.

Just get master branch installed from source on Debian BUllseye per the instructions on QTPYVCP site

and then install from here

github.com/joco-nz/monokrom-vcp

James and I both got busy....

Just get master branch installed from source on Debian BUllseye per the instructions on QTPYVCP site

and then install from here

github.com/joco-nz/monokrom-vcp

James and I both got busy....

The following user(s) said Thank You: Joco, CNCFred, htdave, Ashley

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

17 May 2022 19:21 #243194

by Joco

Replied by Joco on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

This work is being reviewed and should become part of the official qtpyvcp master in the coming days.

I will announce here when the merge is completed.

Thanks.

I will announce here when the merge is completed.

Thanks.

The following user(s) said Thank You: tommylight, rodw, htdave

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

17 May 2022 23:38 - 17 May 2022 23:39 #243220

by Joco

Replied by Joco on topic MonoKrom - QtPyVCP GUI for PlasmaC and Mill

Pleased to announce that the underlying qtpyvcp work that supports monokrom plasma is now merged into the master code line. This means no need to use my repo to access that work and run the monokrom plasma UI.

It is quite a significant add so if anyone hits a problem I might have missed please raise a bug report so we can track, investigate and fix.

Thanks - James.

It is quite a significant add so if anyone hits a problem I might have missed please raise a bug report so we can track, investigate and fix.

Thanks - James.

Last edit: 17 May 2022 23:39 by Joco.

The following user(s) said Thank You: TurBoss, tommylight, rodw, CNCFred

Please Log in or Create an account to join the conversation.

Moderators: KCJ, Lcvette

Time to create page: 0.634 seconds