- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

24 Aug 2021 07:48 #218595

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

24 Aug 2021 19:54 #218640

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

well Tom if it makes you feel any better you are not alone in the Shit out of luck boat  Fedex lost my AC motor and i have been playing phone tag with Automation direct opening up a claim to get the motor i paid $350 for that was due to be delivered a week ago. so i can relate a little bit with having to waste time on stuff that should be simple. i can only imagine if it were imported how much worse it could be.

Fedex lost my AC motor and i have been playing phone tag with Automation direct opening up a claim to get the motor i paid $350 for that was due to be delivered a week ago. so i can relate a little bit with having to waste time on stuff that should be simple. i can only imagine if it were imported how much worse it could be.

if it is worth anything watching you overcome what ever gets in your way is inspirational i wish i had half your drive

i wish i had half your drive

if it is worth anything watching you overcome what ever gets in your way is inspirational

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

24 Aug 2021 23:31 #218658

by Grotius

Replied by Grotius on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Hi,

I was thinking a little bit about how to solve the transatlantic problem's for Tom.

Is it possible to switch over to other interface's, or produce something local.

Almost everything can be connected to lcnc, that should not be the problem.

A plasma machine is a relatively easy setup.

There is a producer in Russia that contacted me in the past. They also produce plasma machines

and they produce also interface's. Russia is not far from Kosovo i guess.

Ethercat would be a professional solution. Selling price of machine's may go up. Ethercat is produced in Germany,

not extremely far from Kosovo.

If you have a adapter socket for a programmable chip, with break out board, for example 50 i-0. Something like a Rpi4.

Or maybe you need even 2 Rpi4's for one machine.

Or maybe a chip that uses Ethercat protocoll mounted on a break out board.

Using a Parport break out $5 is nothing to be ashamed off. It is usable for windows and linux. Cross platform and is usable for plasma machines.

I think you have too look for a second opinion.

I was thinking a little bit about how to solve the transatlantic problem's for Tom.

Is it possible to switch over to other interface's, or produce something local.

Almost everything can be connected to lcnc, that should not be the problem.

A plasma machine is a relatively easy setup.

There is a producer in Russia that contacted me in the past. They also produce plasma machines

and they produce also interface's. Russia is not far from Kosovo i guess.

Ethercat would be a professional solution. Selling price of machine's may go up. Ethercat is produced in Germany,

not extremely far from Kosovo.

If you have a adapter socket for a programmable chip, with break out board, for example 50 i-0. Something like a Rpi4.

Or maybe you need even 2 Rpi4's for one machine.

Or maybe a chip that uses Ethercat protocoll mounted on a break out board.

Using a Parport break out $5 is nothing to be ashamed off. It is usable for windows and linux. Cross platform and is usable for plasma machines.

I think you have too look for a second opinion.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

12 Sep 2021 01:24 #220271

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Started building 6 more machinies, 3 for cutting plates with the following dimensions (so far):

1 @ 2X1.25M

1 @ 2X1.5M

1 @ 1.2X ??M

2 more for cutting round tube @ 3X0.3M and 3 or 6 by 0.5M, have not decided yet on the last one,

and one more for square tube also at 3 or 6X0.4M.

The one for square tube is causing me headaches thinking to pull that off as i would like it to have 5 axis so it can cut sections for trusses without the need for further work cleaning the prats.

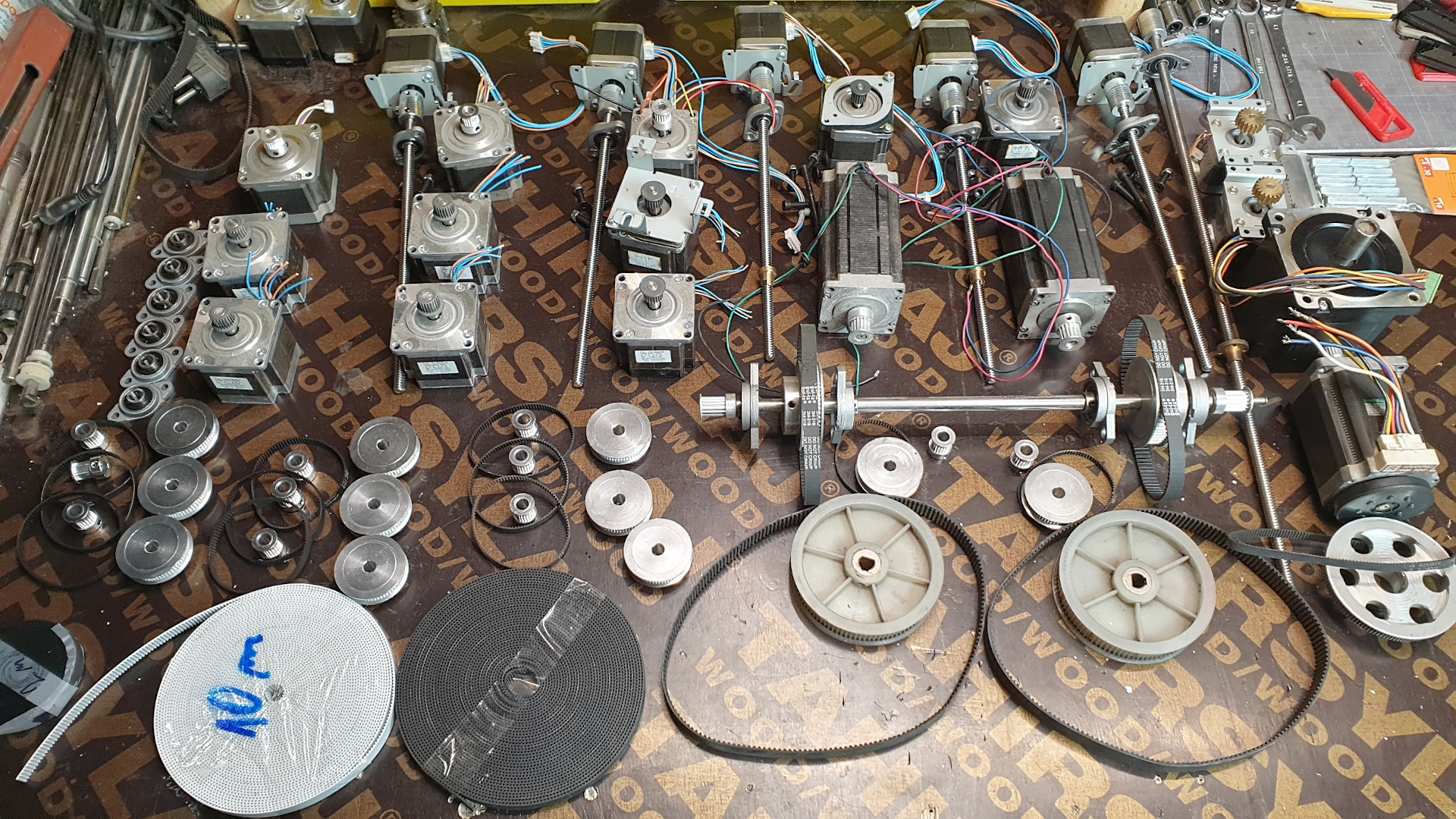

So far i have cut the 150X150X4mm sections for the 3 plate cutting ones, today cut the 300X980X3mm plates to be bent at 90 degrees for legs, already cut the rails at 2.3m x4 and 1.4 x2 - supported round tube as usual at 25mm (still overkill), gathered almost everything required for 6 of Z axis as can be seen below:

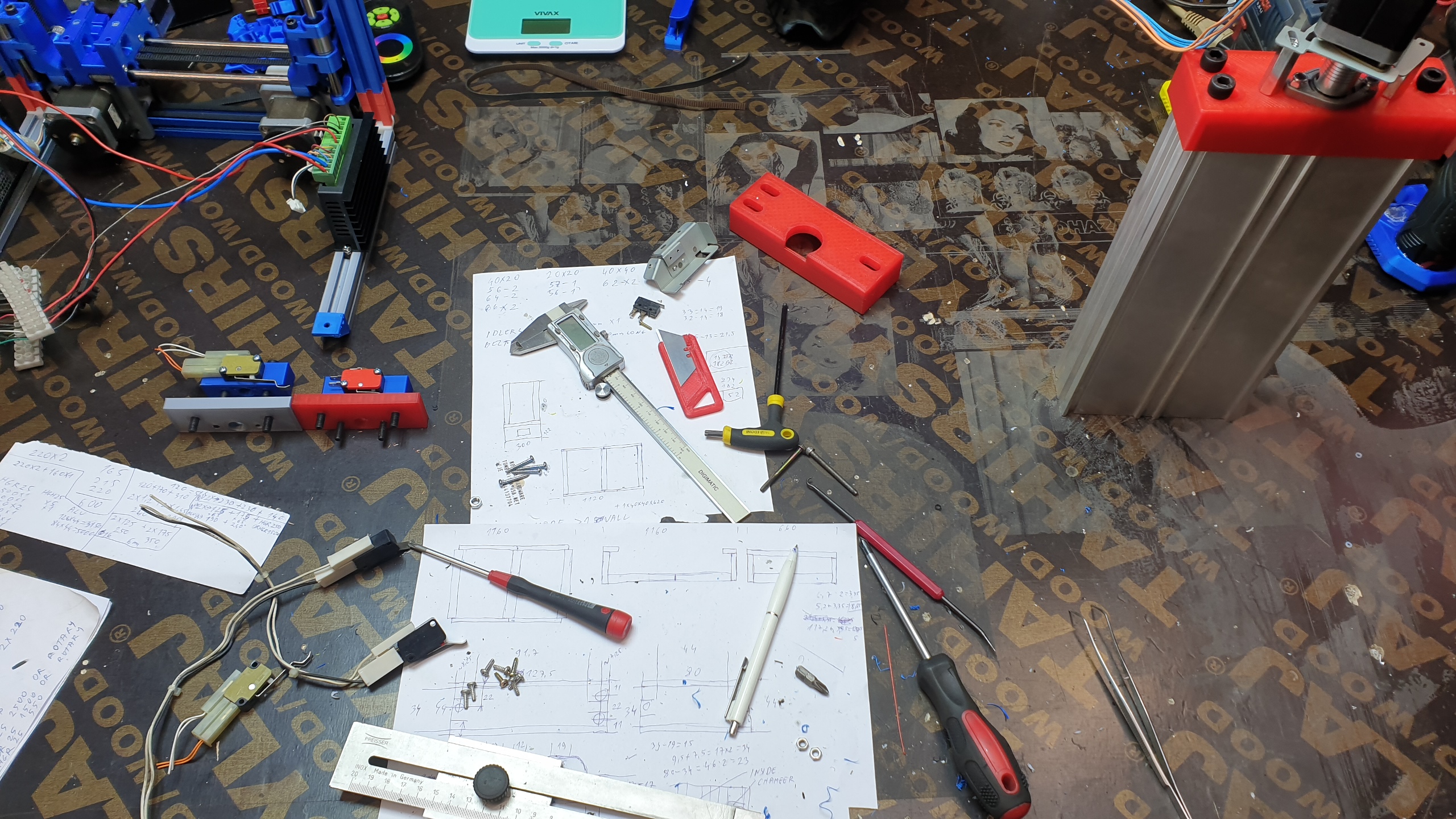

Last 3 days spent learning FreeCAD and designing parts for the Z axis with floating switch to replace all the aluminium parts that take forever to measure, drill, tap, chamfer, clean, bolt together, test fit, dismantle, adjust-scrape-grind-redrill-retap .... and they are still heavy !

So cue in the 3D printers, been designing and testing and ... oh well have a look:

There is also a half full trash can, quite big, but does not look presentable to post here.

From scribbles to actual functioning parts took some doing and some testing and as usual the road to success was riddled with failures, while the strength tests proved way better than expected ! Watching someone testing 3D printing materials and showing graphs with MPa (Mega Pascals) is all nice and dandy (looking at you Stefan of CNC Kitchen fame on youtube) but does nothing to show how many times you can throw a 3D printed part against a wall till it breaks.

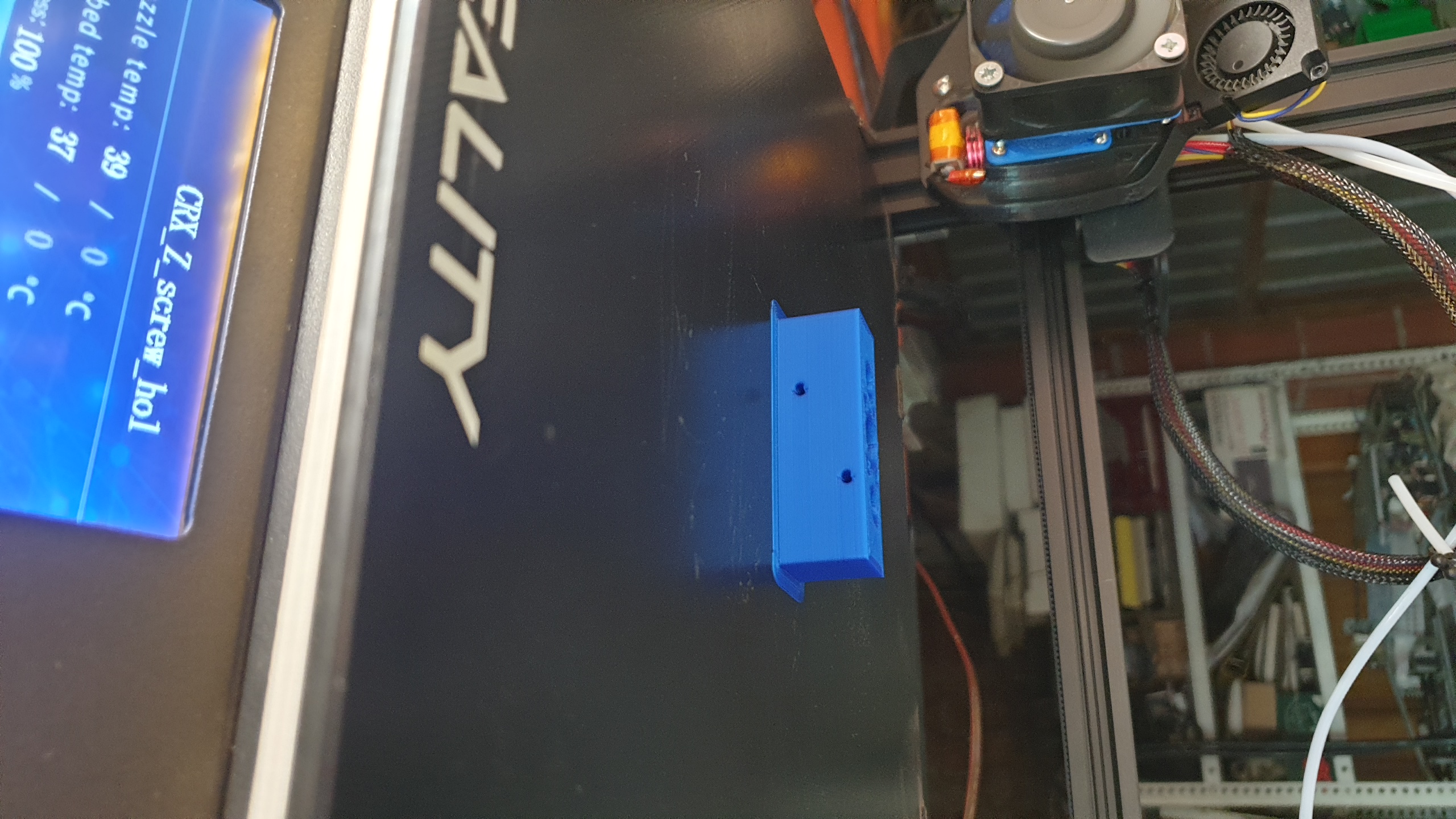

Public service announcement: Do not bother adjusting your monitor, the following picture is of a 3D printer upside down !

1 @ 2X1.25M

1 @ 2X1.5M

1 @ 1.2X ??M

2 more for cutting round tube @ 3X0.3M and 3 or 6 by 0.5M, have not decided yet on the last one,

and one more for square tube also at 3 or 6X0.4M.

The one for square tube is causing me headaches thinking to pull that off as i would like it to have 5 axis so it can cut sections for trusses without the need for further work cleaning the prats.

So far i have cut the 150X150X4mm sections for the 3 plate cutting ones, today cut the 300X980X3mm plates to be bent at 90 degrees for legs, already cut the rails at 2.3m x4 and 1.4 x2 - supported round tube as usual at 25mm (still overkill), gathered almost everything required for 6 of Z axis as can be seen below:

Last 3 days spent learning FreeCAD and designing parts for the Z axis with floating switch to replace all the aluminium parts that take forever to measure, drill, tap, chamfer, clean, bolt together, test fit, dismantle, adjust-scrape-grind-redrill-retap .... and they are still heavy !

So cue in the 3D printers, been designing and testing and ... oh well have a look:

There is also a half full trash can, quite big, but does not look presentable to post here.

From scribbles to actual functioning parts took some doing and some testing and as usual the road to success was riddled with failures, while the strength tests proved way better than expected ! Watching someone testing 3D printing materials and showing graphs with MPa (Mega Pascals) is all nice and dandy (looking at you Stefan of CNC Kitchen fame on youtube) but does nothing to show how many times you can throw a 3D printed part against a wall till it breaks.

Public service announcement: Do not bother adjusting your monitor, the following picture is of a 3D printer upside down !

Attachments:

The following user(s) said Thank You: phillc54, CNCFred, shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

12 Sep 2021 12:39 #220298

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

that's a lot of parts and it looks like someone got a 3D printer  3D printing is something i never got into but seems to be advancing as the years pass. i think i said i wished i had half you drive i think i would be happy with about 10%

3D printing is something i never got into but seems to be advancing as the years pass. i think i said i wished i had half you drive i think i would be happy with about 10%

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- shpatb

-

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 62

12 Sep 2021 16:55 #220340

by shpatb

Replied by shpatb on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Here before this topic reaches 100k views .

Keep it up old man ,You are a beast!

Keep it up old man ,You are a beast!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

12 Sep 2021 21:51 #220372

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

I have 8 and building some more, not that i need that much but i am a hoarder !... and it looks like someone got a 3D printer

You would not, for sure. I avoid reality by keeping myself to busy !i think i said i wished i had half you drive i think i would be happy with about 10%

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

12 Sep 2021 21:52 #220373

by tommylight

Dang if i could do that on youtube, i would be set for life !

Nice,this was mild, now the storm approaches ....

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Wait what ? When did that happen ?Here before this topic reaches 100k views .

Dang if i could do that on youtube, i would be set for life !

Nice,this was mild, now the storm approaches ....

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

12 Sep 2021 22:09 #220375

by tommylight

I am still working on it ....

Locally, nothing is produced. We import everything and export money.

And it is about 3 to 5 thousand KM away, it is a big country!

And Germany is 1300 to 2200 KM away, still a big-ish country !

I like Germany for a lot of things, punctuality, work ethics, no sense of humor ...

Thank you.

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Sorry for the late reply, somehow i missed this.I was thinking a little bit about how to solve the transatlantic problem's for Tom.

I am still working on it ....

It is but i am not going to, i love LinuxCNC and adore HAL !Is it possible to switch over to other interface's, or produce something local.

Locally, nothing is produced. We import everything and export money.

I like Russians, i would love to learn to speak Russian, but i do not like Russia = they were d#ck$ all throughout history, just look for invasion of Finland, North Korea, East Germany, etc. All these are very recent.There is a producer in Russia that contacted me in the past. They also produce plasma machines

and they produce also interface's. Russia is not far from Kosovo i guess.

And it is about 3 to 5 thousand KM away, it is a big country!

This i would like to use, i like Ethercat, i just can not justify the price for what i do. Looked several times at used stuff, not much cheaper than new.Ethercat would be a professional solution. Selling price of machine's may go up. Ethercat is produced in Germany,

not extremely far from Kosovo.

And Germany is 1300 to 2200 KM away, still a big-ish country !

I like Germany for a lot of things, punctuality, work ethics, no sense of humor ...

I never use break out boards, had plenty of them and just gave them away to whoever asked for them, but i do have several machines using parallel port, plasma cutters mostly, in use every day for several years. The only thing that bothers me with it is the low step rate so low microsteping and the subsequent vibrations during slow moves, although when plasma is actually cutting nothing can be heard !Using a Parport break out $5 is nothing to be ashamed off. It is usable for windows and linux. Cross platform and is usable for plasma machines.

Thank you.

The following user(s) said Thank You: shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7233

14 Sep 2021 09:27 #220566

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

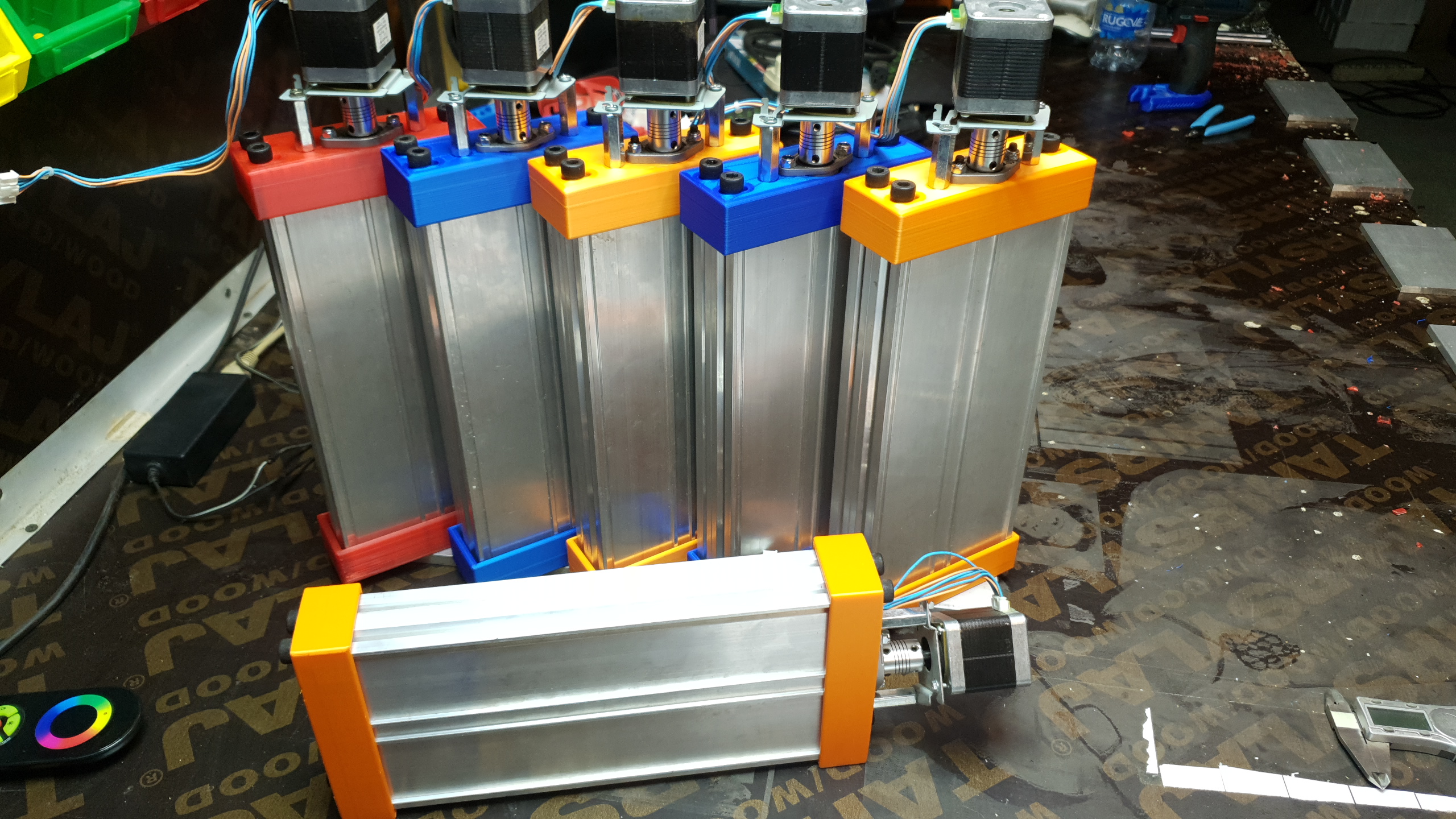

Finished one, waiting for linear bearings should be here today or tomorrow, the finished one came in at under 2.5KG, compared to all aluminium ones i built earlier that were nearly 4KG. Old ones used 16mm diameter rods, this one has 12mm rods while one will have 10mm for testing, should be enough for sure but not sure how they handle raming them into slats at 24M/M !

Also thinking of using mechanical switches for homing/limits as inductive ones i can find have no shielding on the cables so occasionally they do trip.

Moving on....

Also thinking of using mechanical switches for homing/limits as inductive ones i can find have no shielding on the cables so occasionally they do trip.

Moving on....

Attachments:

The following user(s) said Thank You: billykid, phillc54, Clive S, CNCFred, shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.287 seconds