- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

21 Sep 2021 21:04 #221295

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

All 3 gantries are done with belts and reductions and Z axis mounts and hard stops. No limits yet.

Also all 6 uprights for 3 machines are done, now bolting them to gantries.

All this can also be taken as the procedure to build a cnc machine, start from the Z axis, always. Any other way will lead to issues during the way.

Also all 6 uprights for 3 machines are done, now bolting them to gantries.

All this can also be taken as the procedure to build a cnc machine, start from the Z axis, always. Any other way will lead to issues during the way.

Attachments:

The following user(s) said Thank You: shpatb

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

21 Sep 2021 22:42 #221300

by snowgoer540

Replied by snowgoer540 on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

22 Sep 2021 00:24 #221311

by tommylight

Luckily i did not pay for them, or actually i did physically pay for them after a friend sent that money to me, almost all of the miners i have are his by now, had to sell him the last one i had when i built the new shop. He is very generous compensating for electricity and maintenance.

Back on topic, had a visit today regarding some new builds, they already have the metal construction and some servos for a 12X4 meter plasma machine (chalk that to megalomania) so task one is finishing that one, then another plate cutting plasma/oxy at 6X2 meters and a pipe cutting one up to 400mm and a square cutting one up to 500mm.

Yeah, both tube ones are going to be 12 meters long, so just the moving weight is a huge issue.

Oh joy, more to do...

Who is counting, how many machines am i building ????

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Ouch, pretty sure that if you browse back there are two of RX-6900-XT there!also pictured: the elusive high end graphics card

Luckily i did not pay for them, or actually i did physically pay for them after a friend sent that money to me, almost all of the miners i have are his by now, had to sell him the last one i had when i built the new shop. He is very generous compensating for electricity and maintenance.

Back on topic, had a visit today regarding some new builds, they already have the metal construction and some servos for a 12X4 meter plasma machine (chalk that to megalomania) so task one is finishing that one, then another plate cutting plasma/oxy at 6X2 meters and a pipe cutting one up to 400mm and a square cutting one up to 500mm.

Yeah, both tube ones are going to be 12 meters long, so just the moving weight is a huge issue.

Oh joy, more to do...

Who is counting, how many machines am i building ????

The following user(s) said Thank You: shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Sep 2021 00:29 #221312

by phillc54

Replied by phillc54 on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

The following user(s) said Thank You: tommylight, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

22 Sep 2021 11:57 #221334

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Sounds about right !Too many?

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

25 Sep 2021 09:20 #221538

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

So many holes ....

My whole right side of the body is stiff from all the driling and taping, dang it i had forgoten ....

Finished all 6 of the Y axis (150×150×4), mounted legs (L profile 150x150x3), rails (SBR25) and 2 carriages each.

Pretty sure one of the Bosch drills had enough as it started stinking!

Now some more holes to bolt the gantries and belts, and later to mount the "skirt" = side plates.

Missing 8 of KFL08 bearings for the reductions, waiting...

Also missing a lot of electronics, from Mesa boards to drives (although i do have plenty of drives but full step or half step only = noisy), thinking of switching one to servo as i have some small 20 to 80W motors and some "arduino" drives and from previous testing they work nicely when paired with a Mesa 5i25/6i25 or 7i92, but will require more shielded cable that is very hard to find here, before used some "camera" cables but it cr@ps out after 2 to 3 months of use so no more.

More pictures to follow ...

My whole right side of the body is stiff from all the driling and taping, dang it i had forgoten ....

Finished all 6 of the Y axis (150×150×4), mounted legs (L profile 150x150x3), rails (SBR25) and 2 carriages each.

Pretty sure one of the Bosch drills had enough as it started stinking!

Now some more holes to bolt the gantries and belts, and later to mount the "skirt" = side plates.

Missing 8 of KFL08 bearings for the reductions, waiting...

Also missing a lot of electronics, from Mesa boards to drives (although i do have plenty of drives but full step or half step only = noisy), thinking of switching one to servo as i have some small 20 to 80W motors and some "arduino" drives and from previous testing they work nicely when paired with a Mesa 5i25/6i25 or 7i92, but will require more shielded cable that is very hard to find here, before used some "camera" cables but it cr@ps out after 2 to 3 months of use so no more.

More pictures to follow ...

The following user(s) said Thank You: phillc54, Clive S, shpatb, snowgoer540

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

29 Sep 2021 13:51 #221829

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

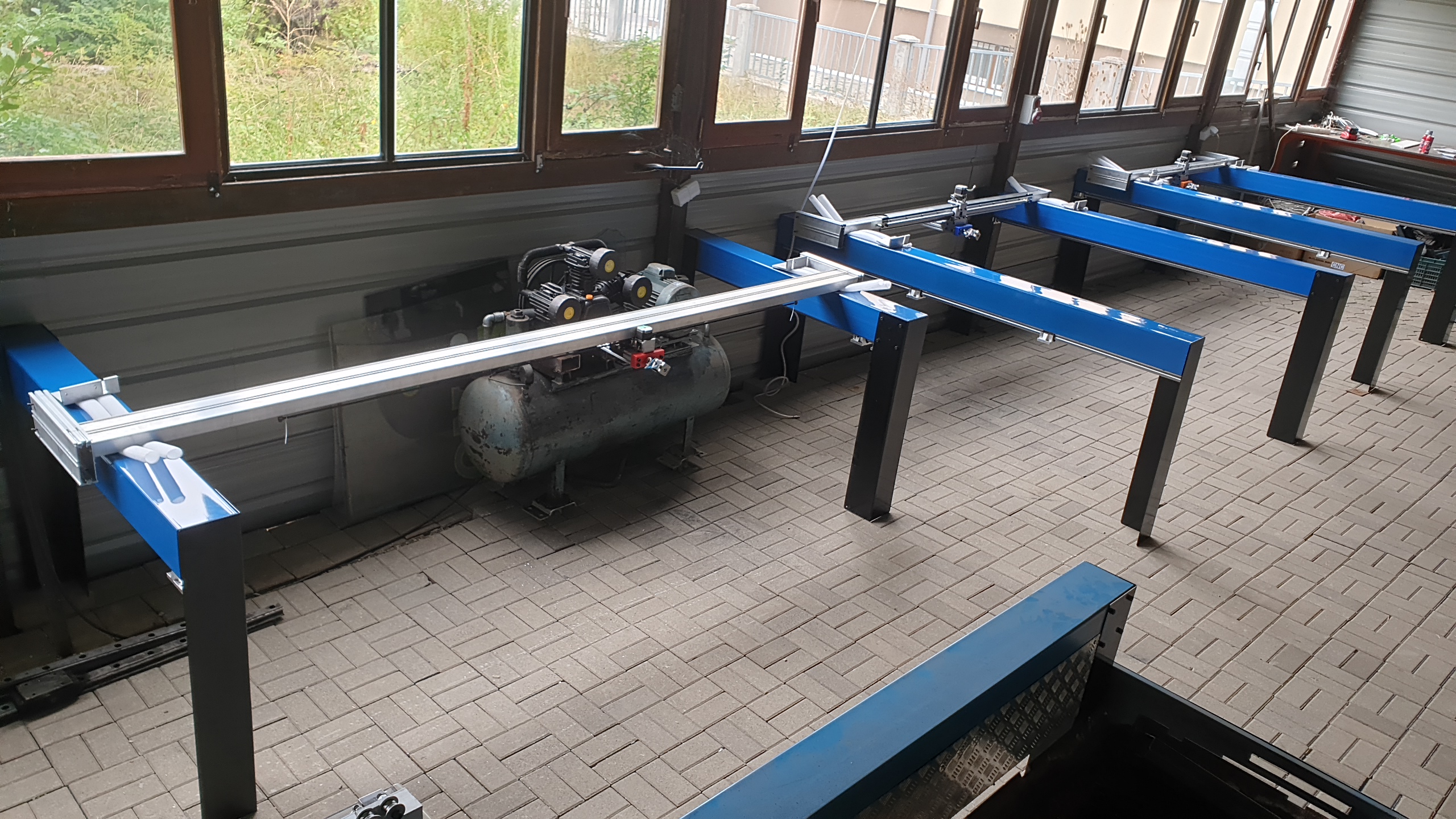

This is the current state of the 3 ongoing builds, gantries are not bolted to the Y axis yet, same for the reductions (might mount them today, who knows  ), the design>cut>paint>mount the side skirts/panels, and that should be it ... for the mechanics since electronics are still waiting on the table or somewhere around the world!

), the design>cut>paint>mount the side skirts/panels, and that should be it ... for the mechanics since electronics are still waiting on the table or somewhere around the world!

Powder coating came out really nice this time and got done in 5 days so me is a happy camper.

Also a video of the big new shop that got small fairly quickly !

Powder coating came out really nice this time and got done in 5 days so me is a happy camper.

Also a video of the big new shop that got small fairly quickly !

Attachments:

The following user(s) said Thank You: billykid, phillc54, Joco, snowgoer540

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

29 Sep 2021 17:49 #221846

by Joco

Replied by Joco on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Tommy - looking impressive as always. On the gantry beam that has the single linear rail, would it be possible to see a couple of pics of how you are mounting the drive motor, reduction gearing and the belt connection. Im debating with myself on different layouts for this and seeing how someone with vastly more experience has done it might keep me from doing a dumb ass design choice. ie over complicating it.

cheers - James.

cheers - James.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

29 Sep 2021 19:32 #221848

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

that blue paint looks familiar i can't put my finger on it

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

29 Sep 2021 23:13 #221859

by tommylight

Wasted nearly two days with it but could not shoehorn reduction into 70X80mm area, not even with a Nema 21 motor, also had to use 6mm wide belt as the space between the Z assembly and the gantry is 42mm minus 8mm alu plate minus some tolerance ....

It did not go well, at all, so it is directly driven with said Nema 21 Sanyo-Denki 1.8A motor. It will work but not a good solution by any means, HGH25 carriages have wipers on both sides so they do require some force just to move them, do not want to have to clean the rails before every probe just to be sure a spec of dust does not cause it to skip steps!

The rest has reductions, so pictures tomorrow, might want to remind me as i might be spaced out a bit, my youngest brother is also moving to USA and he is off tomorrow evening....

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Off course, except there is no reduction or gearing ...On the gantry beam that has the single linear rail, would it be possible to see a couple of pics of how you are mounting the drive motor, reduction gearing and the belt connection.

Wasted nearly two days with it but could not shoehorn reduction into 70X80mm area, not even with a Nema 21 motor, also had to use 6mm wide belt as the space between the Z assembly and the gantry is 42mm minus 8mm alu plate minus some tolerance ....

It did not go well, at all, so it is directly driven with said Nema 21 Sanyo-Denki 1.8A motor. It will work but not a good solution by any means, HGH25 carriages have wipers on both sides so they do require some force just to move them, do not want to have to clean the rails before every probe just to be sure a spec of dust does not cause it to skip steps!

The rest has reductions, so pictures tomorrow, might want to remind me as i might be spaced out a bit, my youngest brother is also moving to USA and he is off tomorrow evening....

The following user(s) said Thank You: Joco

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.322 seconds