- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20938

- Thank you received: 7132

09 Mar 2020 16:45 #159584

by tommylight

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build. was created by tommylight

Had to make a tough decision in this case decide to endure a lot of pain and suffering trying to build a single 6X2m machine in my cramped workshop, or cut the rails and do one 3X2m and one 2.5X1.5m.

There was no space to mount the 6x2m frame, no matter how i looked at it as that ends up in the 7X2.5m outside dimensions. It was a hard decision for sure, and it will hurt even more when cutting the rails that took so long to get here. Never mind, enough mopping, move on to the build, or lack of in this case....

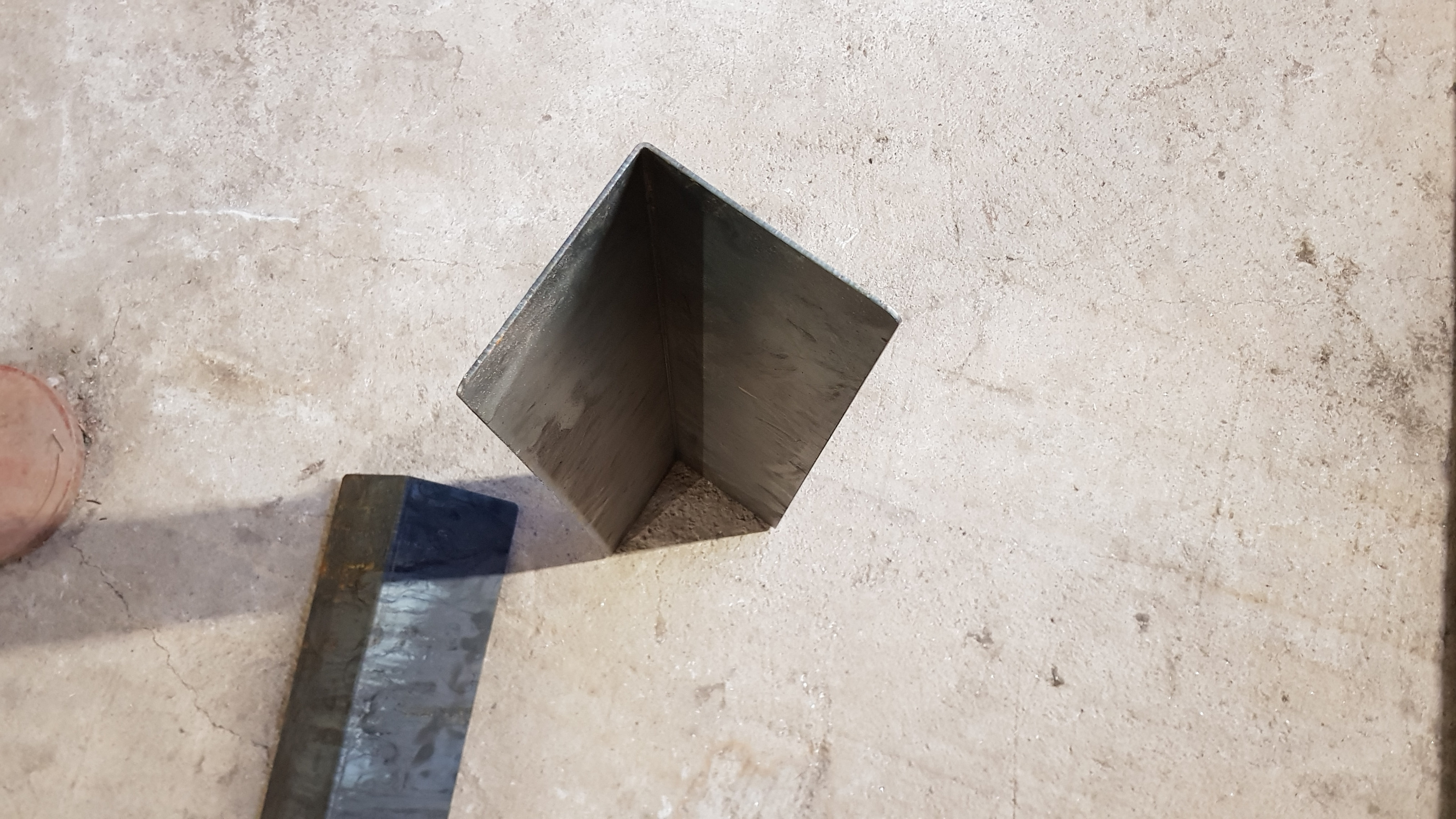

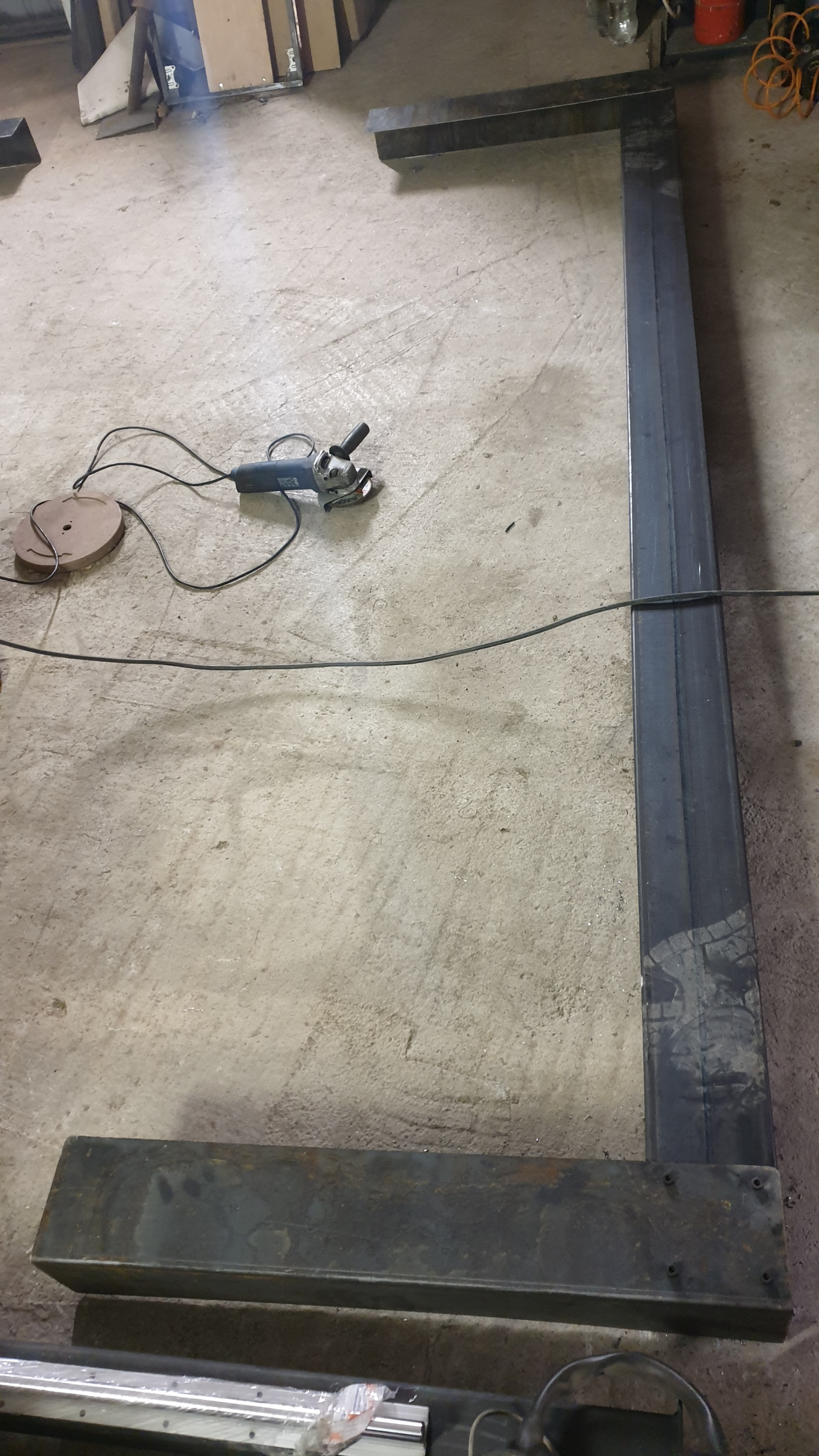

So far i have the outer beams from 150X150X4mm profile and 300X900X4mm sheets bent at 90 degrees to use as legs, here is a pitiful picture of all that on the workshop floor:

And here are the legs made out of sheets:

Those will be bolted to the sides of the beams so they will also cover the openings.

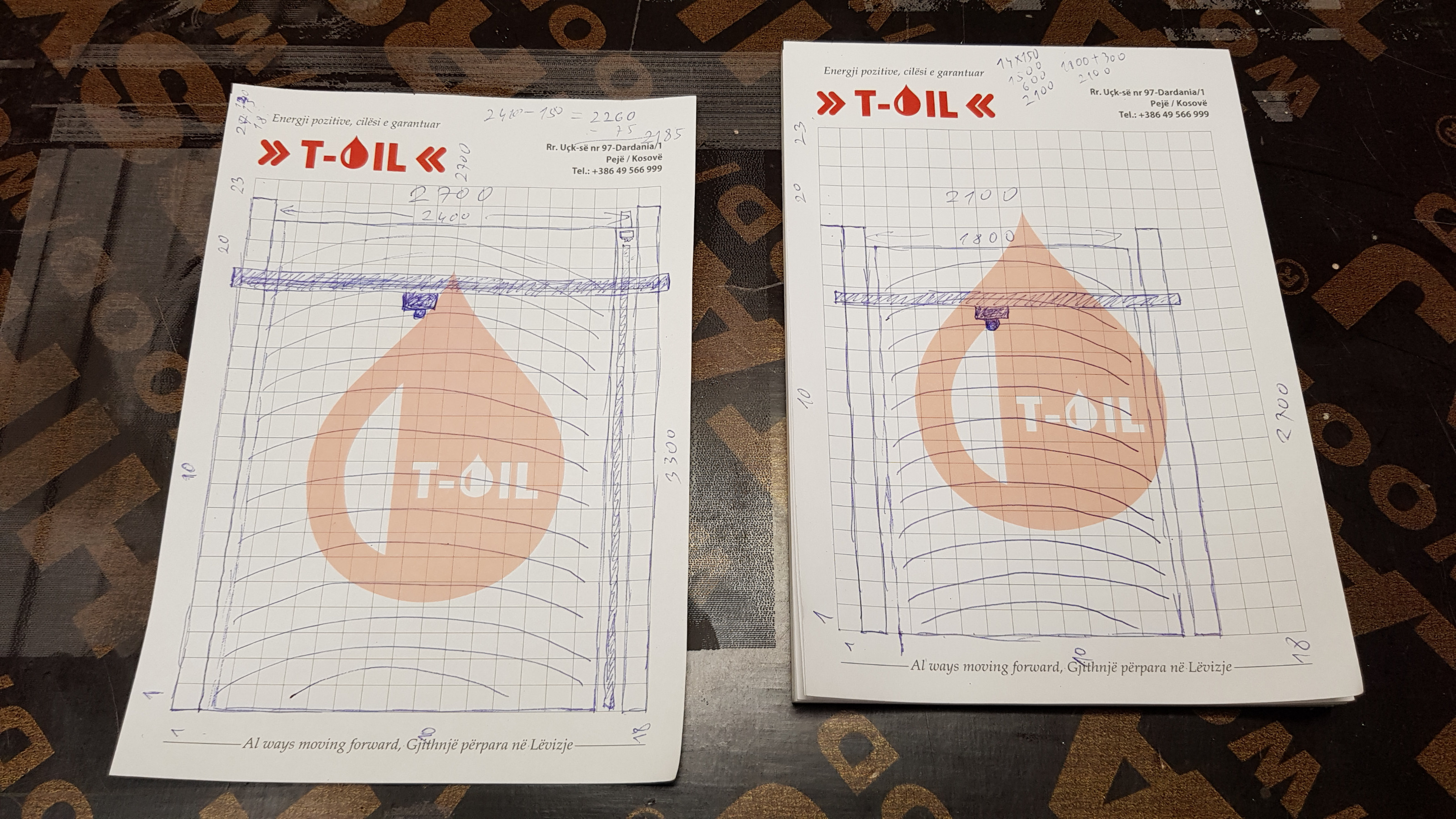

As a bonus, here are some scribbles i made yesterday while sipping "double choka mocca" in the shop, leaving the explanation of them to future generations of archeologists !

Stay tuned ......

There was no space to mount the 6x2m frame, no matter how i looked at it as that ends up in the 7X2.5m outside dimensions. It was a hard decision for sure, and it will hurt even more when cutting the rails that took so long to get here. Never mind, enough mopping, move on to the build, or lack of in this case....

So far i have the outer beams from 150X150X4mm profile and 300X900X4mm sheets bent at 90 degrees to use as legs, here is a pitiful picture of all that on the workshop floor:

And here are the legs made out of sheets:

Those will be bolted to the sides of the beams so they will also cover the openings.

As a bonus, here are some scribbles i made yesterday while sipping "double choka mocca" in the shop, leaving the explanation of them to future generations of archeologists !

Stay tuned ......

Attachments:

The following user(s) said Thank You: phillc54, thefabricator03, CNCFred, dvn4life1972

Please Log in or Create an account to join the conversation.

- jay1st

-

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

10 Mar 2020 07:44 #159636

by jay1st

Replied by jay1st on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

And you are going to make us envious again !!!

Nice builds

Nice builds

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

10 Mar 2020 08:23 #159637

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

most people just built one machine at a time, Tommy is is damn good at tossing these things together he does two at a time  i think he has built at least a half a dozen machines since i got here and i am still working on my first one

i think he has built at least a half a dozen machines since i got here and i am still working on my first one

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20938

- Thank you received: 7132

10 Mar 2020 13:17 #159650

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time.........

Last few weeks i have done close to nothing, chasing parts, organizing some things around, getting p.o. at myself for a lot of reasons, etc, etc, etc, etc, etc,.......

So all in all not productive at all, although i just closed a deal and made the first payment for two work shops with some 170m2 total, and that is not for me. Also have to get some office space, already found a nice place near those two shops. Now a lot of work has to be done in painting and interior design and set up, starting in two weeks, and that will take another 2 or 3 weeks of my time. Had to include some friends/workers as i am frustrated about trying to do everything by myself, it takes to long.

Will let you all know what and how and everything in time, we already have some nice products ready for sale, namely some light fixtures made out of 60 year old reclaimed wood from train tracks bought in bulk from ex-Yougoslavia railways, most of them still have the original stamps with the date of manufacturing on them. They are all hand crafted and look nice, each piece is chosen for each product to match the rope or the chain attached to it.

Will do a separate thread when i get the pictures from the professional photographer/my brother, it is disrespectful to take pictures of them with a phone camera.

Thank you, all.

Last few weeks i have done close to nothing, chasing parts, organizing some things around, getting p.o. at myself for a lot of reasons, etc, etc, etc, etc, etc,.......

So all in all not productive at all, although i just closed a deal and made the first payment for two work shops with some 170m2 total, and that is not for me. Also have to get some office space, already found a nice place near those two shops. Now a lot of work has to be done in painting and interior design and set up, starting in two weeks, and that will take another 2 or 3 weeks of my time. Had to include some friends/workers as i am frustrated about trying to do everything by myself, it takes to long.

Will let you all know what and how and everything in time, we already have some nice products ready for sale, namely some light fixtures made out of 60 year old reclaimed wood from train tracks bought in bulk from ex-Yougoslavia railways, most of them still have the original stamps with the date of manufacturing on them. They are all hand crafted and look nice, each piece is chosen for each product to match the rope or the chain attached to it.

Will do a separate thread when i get the pictures from the professional photographer/my brother, it is disrespectful to take pictures of them with a phone camera.

Thank you, all.

The following user(s) said Thank You: jay1st

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

11 Mar 2020 00:00 #159720

by BigJohnT

Replied by BigJohnT on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Can't wait to see what you come up with!

JT

JT

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- jay1st

-

- Offline

- Premium Member

-

Less

More

- Posts: 127

- Thank you received: 17

11 Mar 2020 07:23 #159751

by jay1st

Replied by jay1st on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Looking good though it seems to be a lot of work !!!

Like BigJohn, can't wait to see the result

Like BigJohn, can't wait to see the result

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20938

- Thank you received: 7132

12 Mar 2020 15:34 #159882

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Here is a snippet of a brain fart i had some days ago while i was staring at those 150x150 profiles and wondering how to make the legs and cover the openings on both sides, that is when the L shaped plate was inception-ed and here is the result of that:

Here is one side :

And here are both sides mounted:

Notice the small gap on the part that is covering the opening of the 150x150mm profile, the L was shaped over 90 degrees so i had trouble getting it that close. Beating it with a hammer was not an option, no matter how much i would have enjoyed it !

Since this has proven usable, looks good, saved a lot of work in welding/cleaning the openings, is easy to dismantle and assemble, i am going to order 4 more of those L shapes fro the second machine.

The SBR30 rails are going to be mounted on the underside of the 150x150mm, the outer side of the machine, that way they will be covered from dust and water. It would have been much easier to mount them above, but i fear some less coordinated person working with it might drop a 500Kg plate on the rails, rendering the machine useless and warranting a 400 euro replacement.

Also got some pieces of Alu profiles that i am hoping to use for the gantry, two dimensions, 84x44 and 124x44 outer dimensions, 4mm walls on the sides, 6mm above and below or the narrow sides. Looking into mounting the reduction and belt tension inside them completely so only the motor can be seen from the outside.

Complicating things to the MAX !

Here is one side :

And here are both sides mounted:

Notice the small gap on the part that is covering the opening of the 150x150mm profile, the L was shaped over 90 degrees so i had trouble getting it that close. Beating it with a hammer was not an option, no matter how much i would have enjoyed it !

Since this has proven usable, looks good, saved a lot of work in welding/cleaning the openings, is easy to dismantle and assemble, i am going to order 4 more of those L shapes fro the second machine.

The SBR30 rails are going to be mounted on the underside of the 150x150mm, the outer side of the machine, that way they will be covered from dust and water. It would have been much easier to mount them above, but i fear some less coordinated person working with it might drop a 500Kg plate on the rails, rendering the machine useless and warranting a 400 euro replacement.

Also got some pieces of Alu profiles that i am hoping to use for the gantry, two dimensions, 84x44 and 124x44 outer dimensions, 4mm walls on the sides, 6mm above and below or the narrow sides. Looking into mounting the reduction and belt tension inside them completely so only the motor can be seen from the outside.

Complicating things to the MAX !

The following user(s) said Thank You: phillc54, jay1st

Please Log in or Create an account to join the conversation.

- CNCFred

-

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

20 Mar 2020 18:42 #160924

by CNCFred

Replied by CNCFred on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

since beating with a hammer was no option you jumped on it! proof of footprints

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20938

- Thank you received: 7132

20 Mar 2020 21:15 #160946

by tommylight

BTW, i have already installed the rails on the big one, tomorrow will do the same on the small one.

More pictures tomorrow.......

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

LOL, not a good criminal, leaving footprints all over the place !since beating with a hammer was no option you jumped on it! proof of footprints

BTW, i have already installed the rails on the big one, tomorrow will do the same on the small one.

More pictures tomorrow.......

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 20938

- Thank you received: 7132

22 Mar 2020 00:13 #161039

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Some progress made and some pictures:

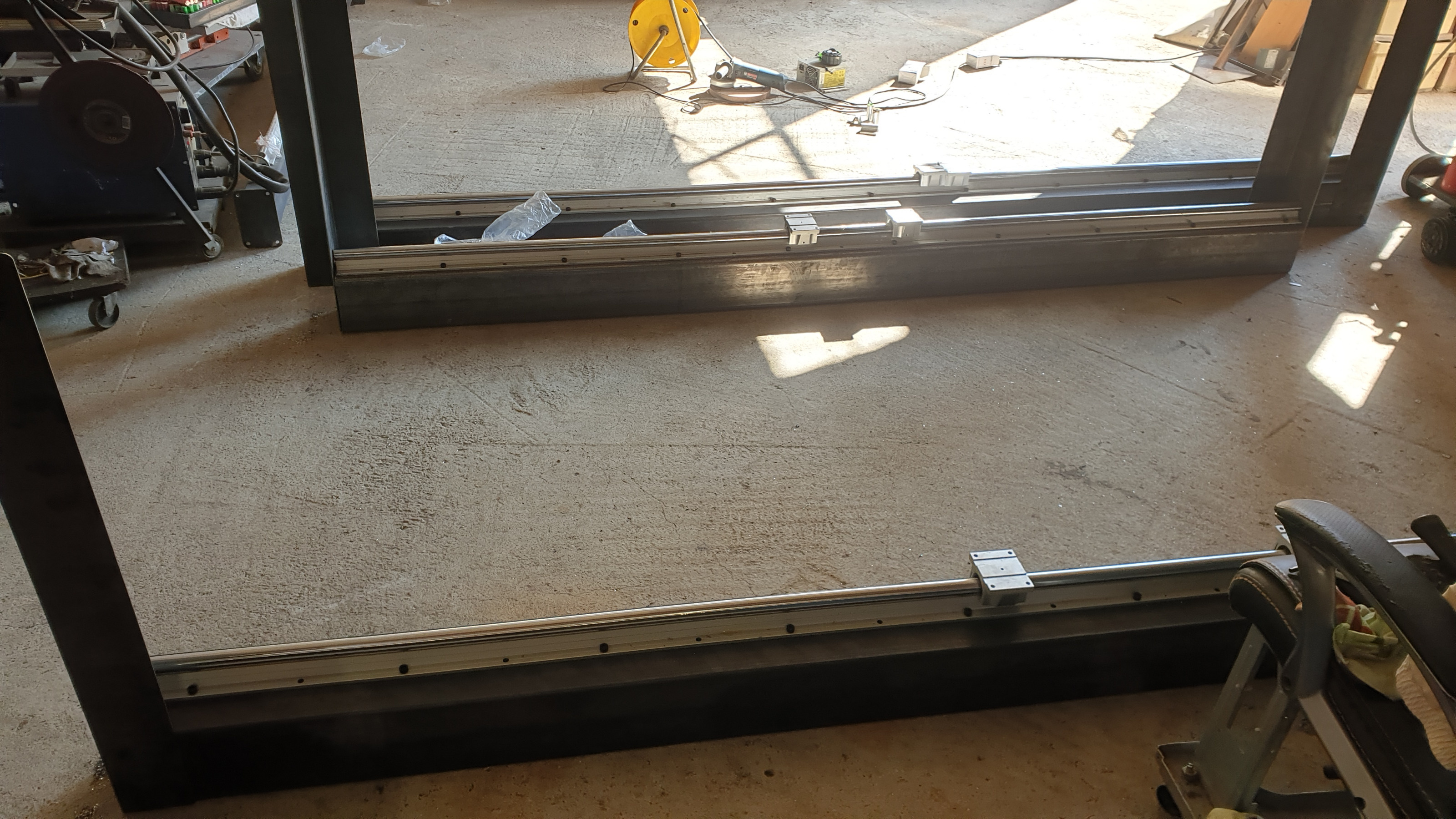

All side "L" mounted, rails cut to size for the small one (model T1525, 1.5X2.5M) and test fitted, the rails on the big one are already bolted in.

All rails will be bolted in a zig-zag pattern, just in case i might need to move them to a different mounting place, there will be a lot of things "hidden" under there, that will take a lot of "measure once, cut twice" building technique implementation. Also notice the SAE90 oil dripping all over from the carriages, i am sure that they will never get oiled again after they go out of this shop.

This is one of the sides with rails attached and in "normal" orientation, all the others are still upside down.

All the rails and carriages in place, for now,

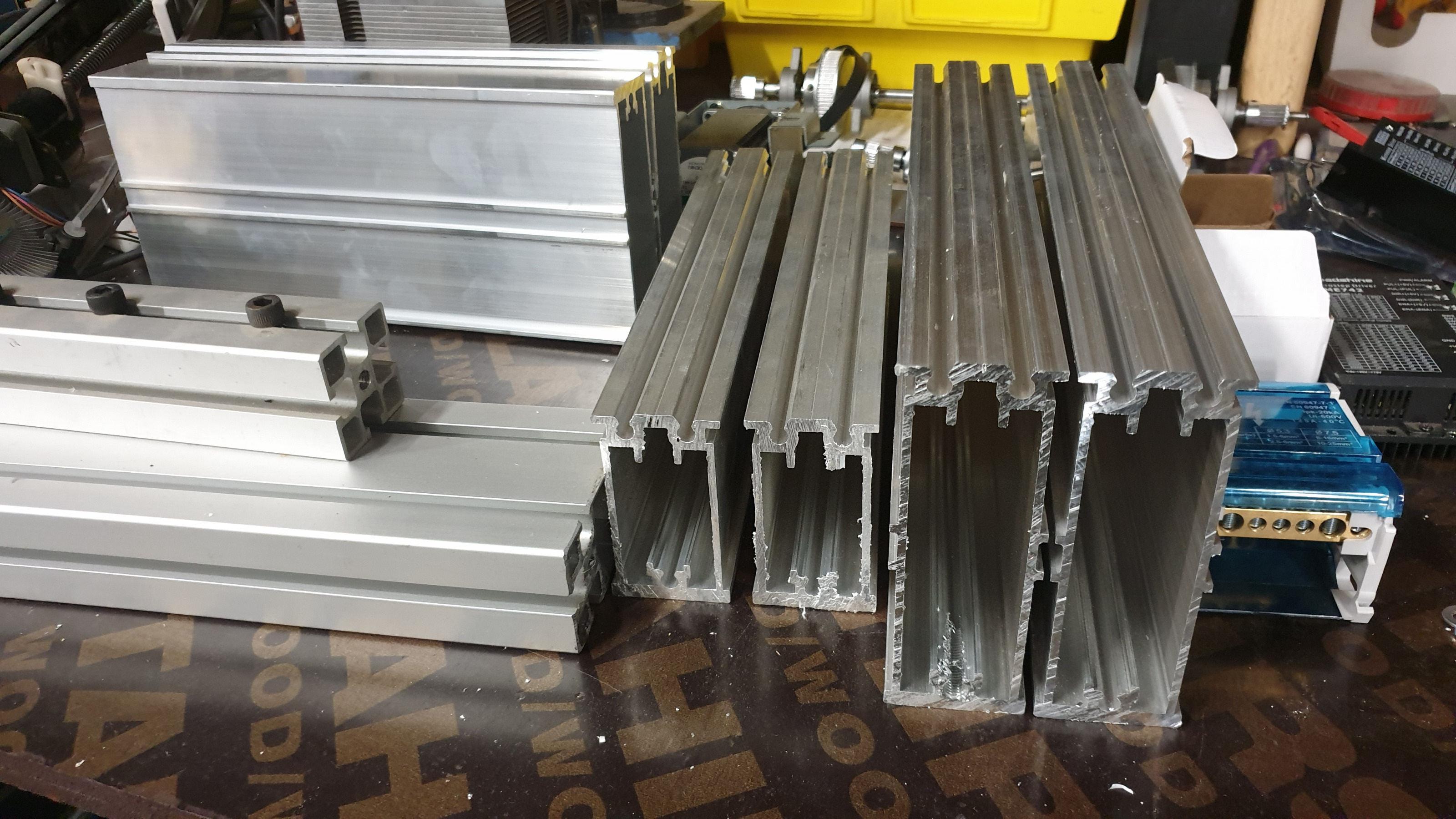

Some aluminum parts that will become "uprights" , but having some issue with hiding the motors and reduction and belt drive in there, not much space anywhere when all the stuff gets added and i am trying to hide everything so it looks "neat" from the outside.

Already assembled the test electronics and motors, not using the expensive stuff until this gets back from powder coating and gets assembled again. I used to use the new stuff while building, by the end it was not new anymore, so now i use old stuff for fitting and testing. China drives, Japan motors and a 24V/16.5A power supply, needs 2 more relays to be added.

Waiting for some L shaped aluminum, 80X40X8mm, it is about 3KM far from me but it is 3.5M long so it wont fit in my car, i did try. Must take the cordless circular saw and chop it to smaller pieces there. Just remembered, i have to order some side panels that have to be cnc cut. Any ideas what to put there ?

All side "L" mounted, rails cut to size for the small one (model T1525, 1.5X2.5M) and test fitted, the rails on the big one are already bolted in.

All rails will be bolted in a zig-zag pattern, just in case i might need to move them to a different mounting place, there will be a lot of things "hidden" under there, that will take a lot of "measure once, cut twice" building technique implementation. Also notice the SAE90 oil dripping all over from the carriages, i am sure that they will never get oiled again after they go out of this shop.

This is one of the sides with rails attached and in "normal" orientation, all the others are still upside down.

All the rails and carriages in place, for now,

Some aluminum parts that will become "uprights" , but having some issue with hiding the motors and reduction and belt drive in there, not much space anywhere when all the stuff gets added and i am trying to hide everything so it looks "neat" from the outside.

Already assembled the test electronics and motors, not using the expensive stuff until this gets back from powder coating and gets assembled again. I used to use the new stuff while building, by the end it was not new anymore, so now i use old stuff for fitting and testing. China drives, Japan motors and a 24V/16.5A power supply, needs 2 more relays to be added.

Waiting for some L shaped aluminum, 80X40X8mm, it is about 3KM far from me but it is 3.5M long so it wont fit in my car, i did try. Must take the cordless circular saw and chop it to smaller pieces there. Just remembered, i have to order some side panels that have to be cnc cut. Any ideas what to put there ?

Attachments:

The following user(s) said Thank You: phillc54, dvn4life1972, Masiwood123

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.369 seconds