- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

26 Apr 2020 20:19 #165690

by tommylight

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Built another two of the reductions for the big machine ( big = 3X2M cut area, small = 2.5X1.5M cut area ), so i took some pictures.

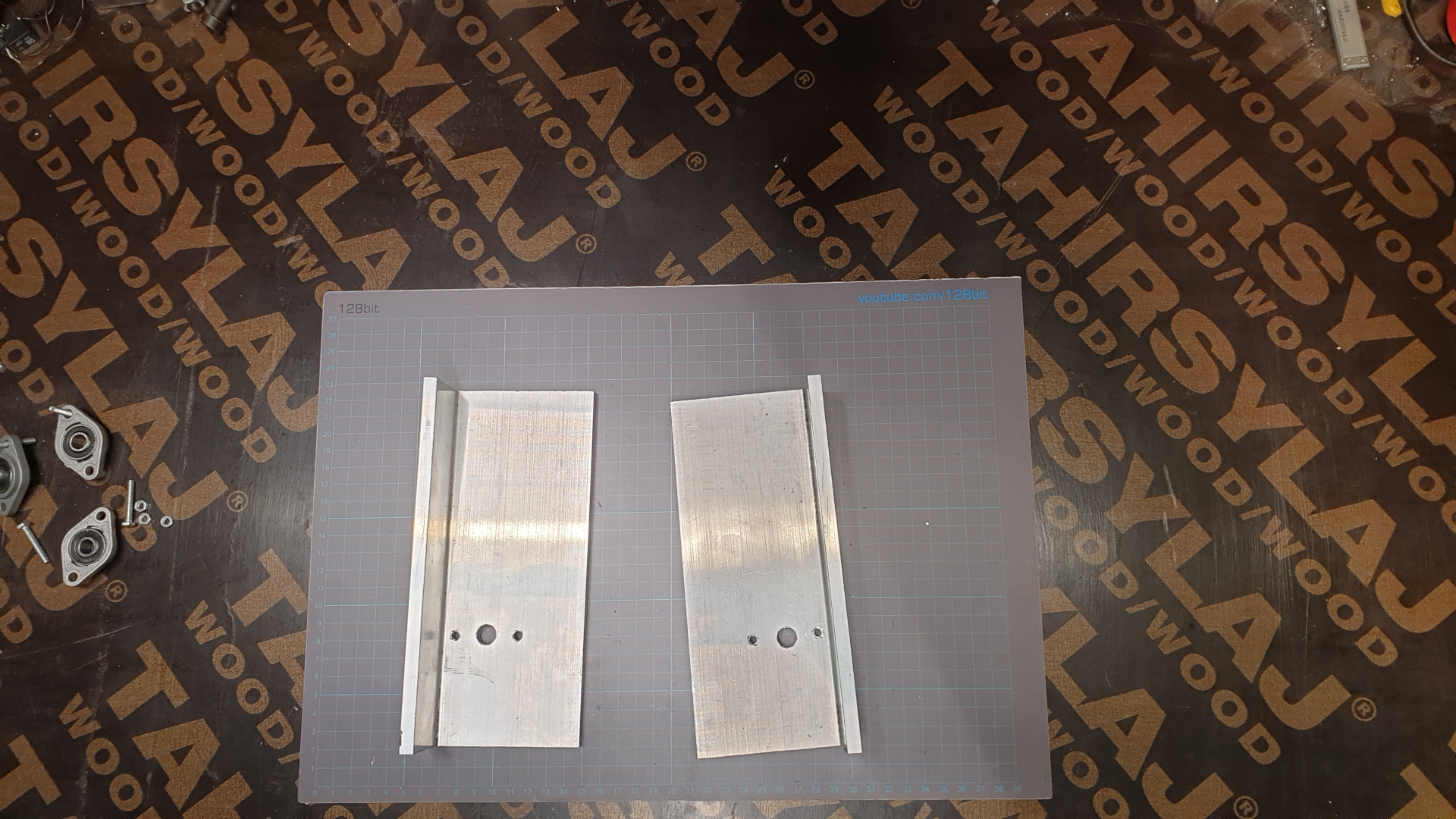

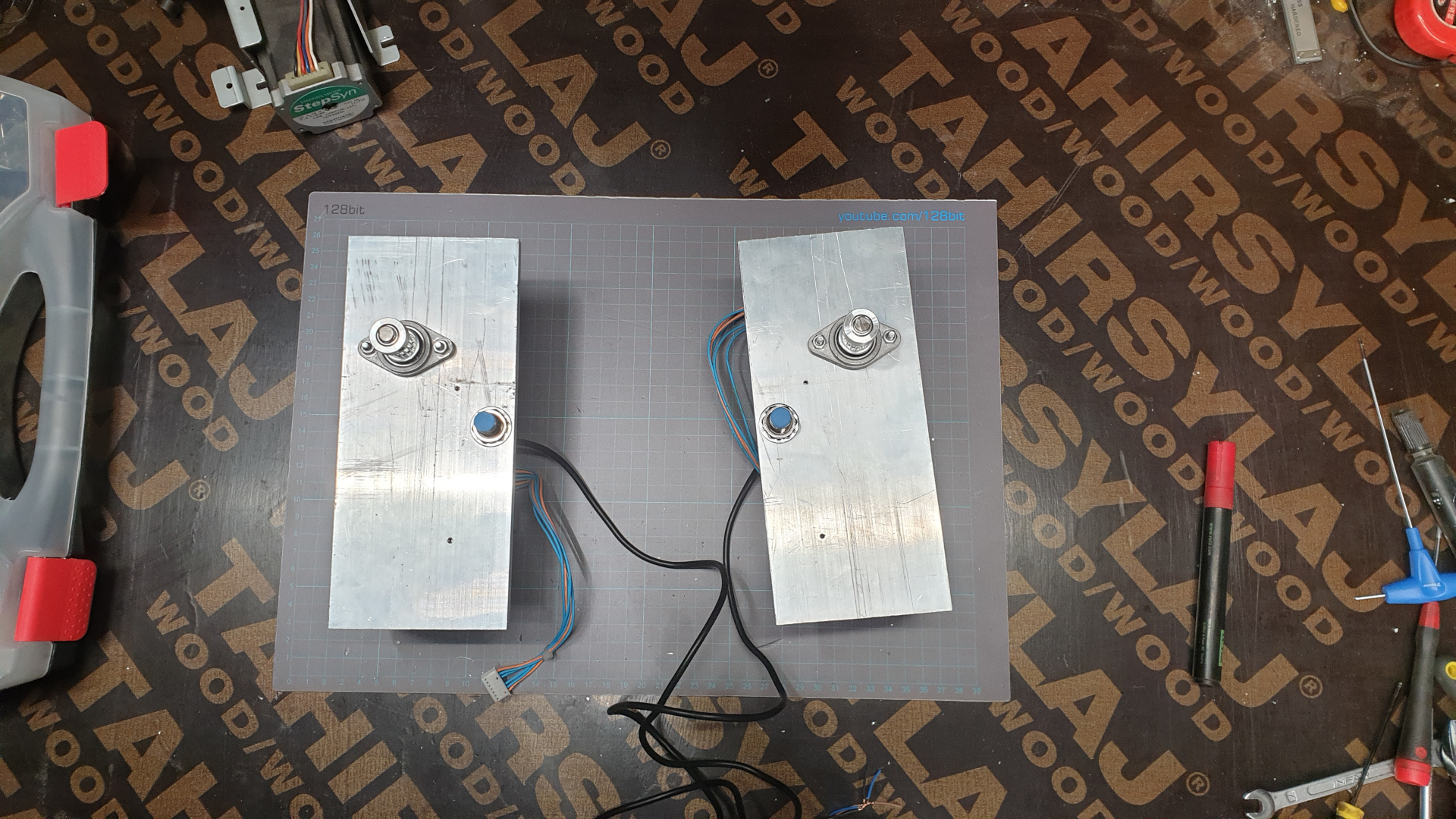

L shaped alu profile 90X50mm, 8mm thick, 200mm long, 2 pieces, holes drilled for the shaft and bearing screws:

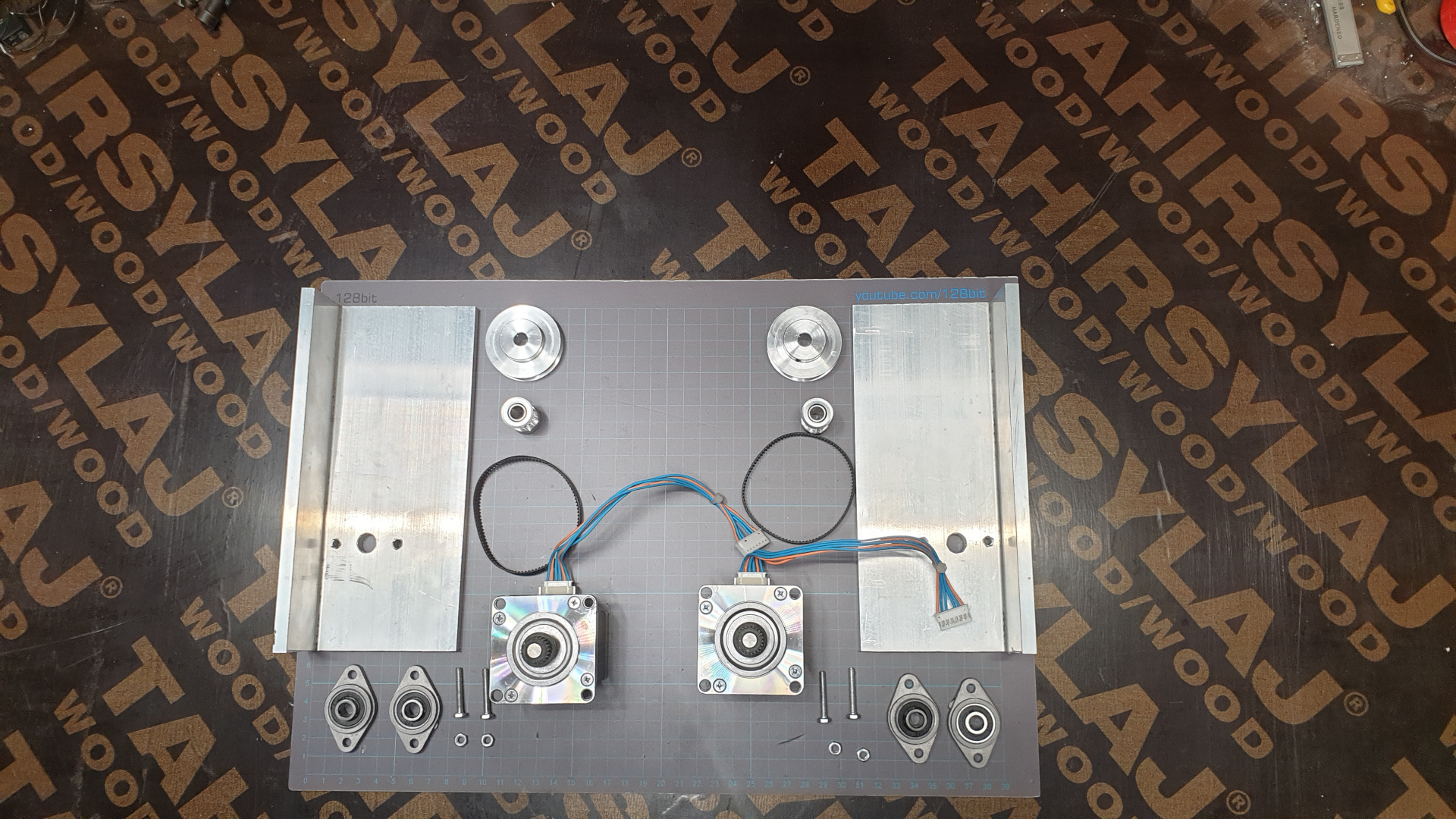

Two bearing with holder and two screws/nuts for each side:

GT2 60 teeth for the motor side, motor pulley is already on the motor, and T3 15 tooth pulley for the driving side, for 15mm wide belt.

Two Nema 23 stepper motors, used ones till they are mounted on the machine, then new ones double length:

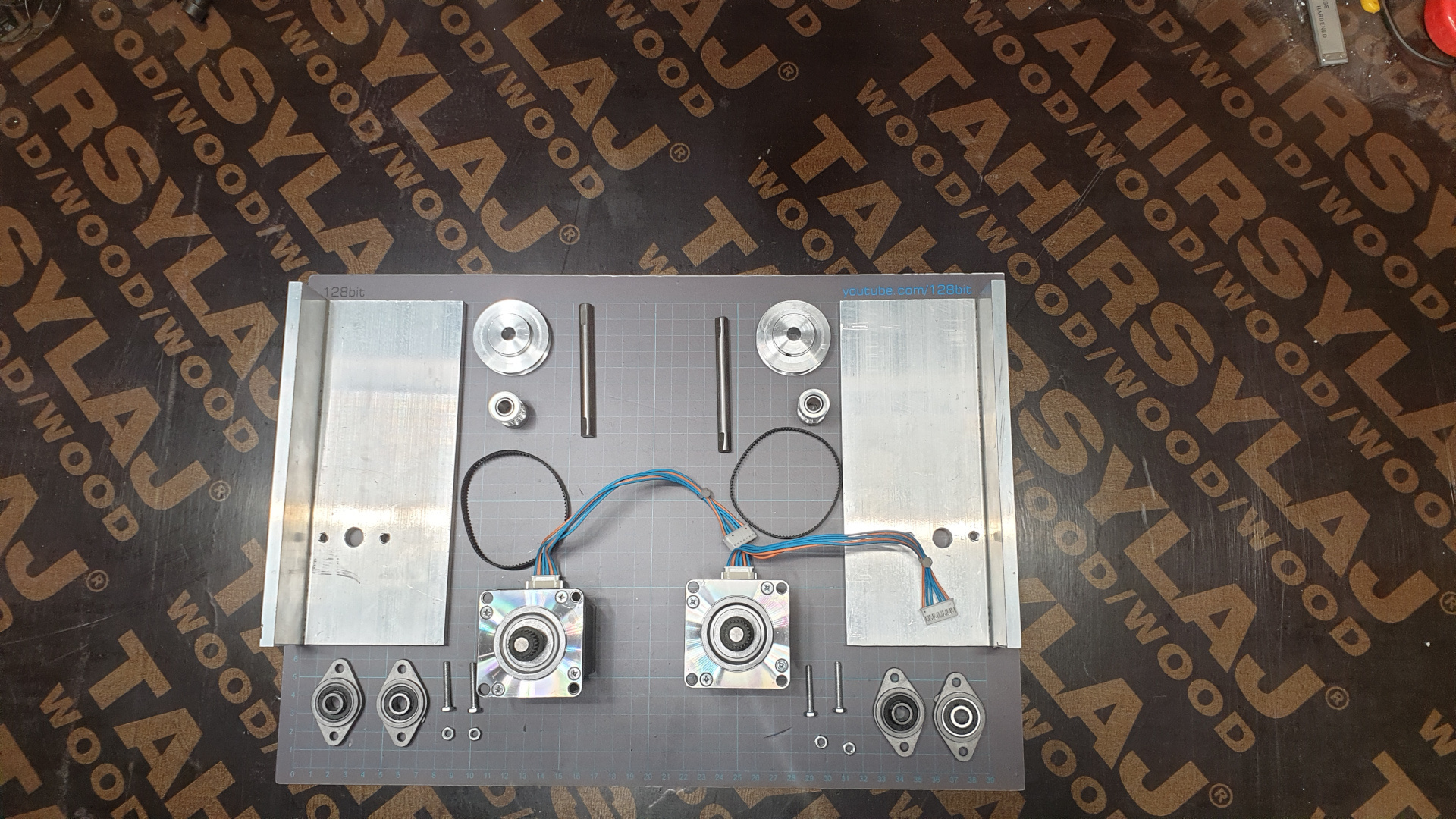

Two 8mm shafts, both sides have two ground parts to prevent slipping:

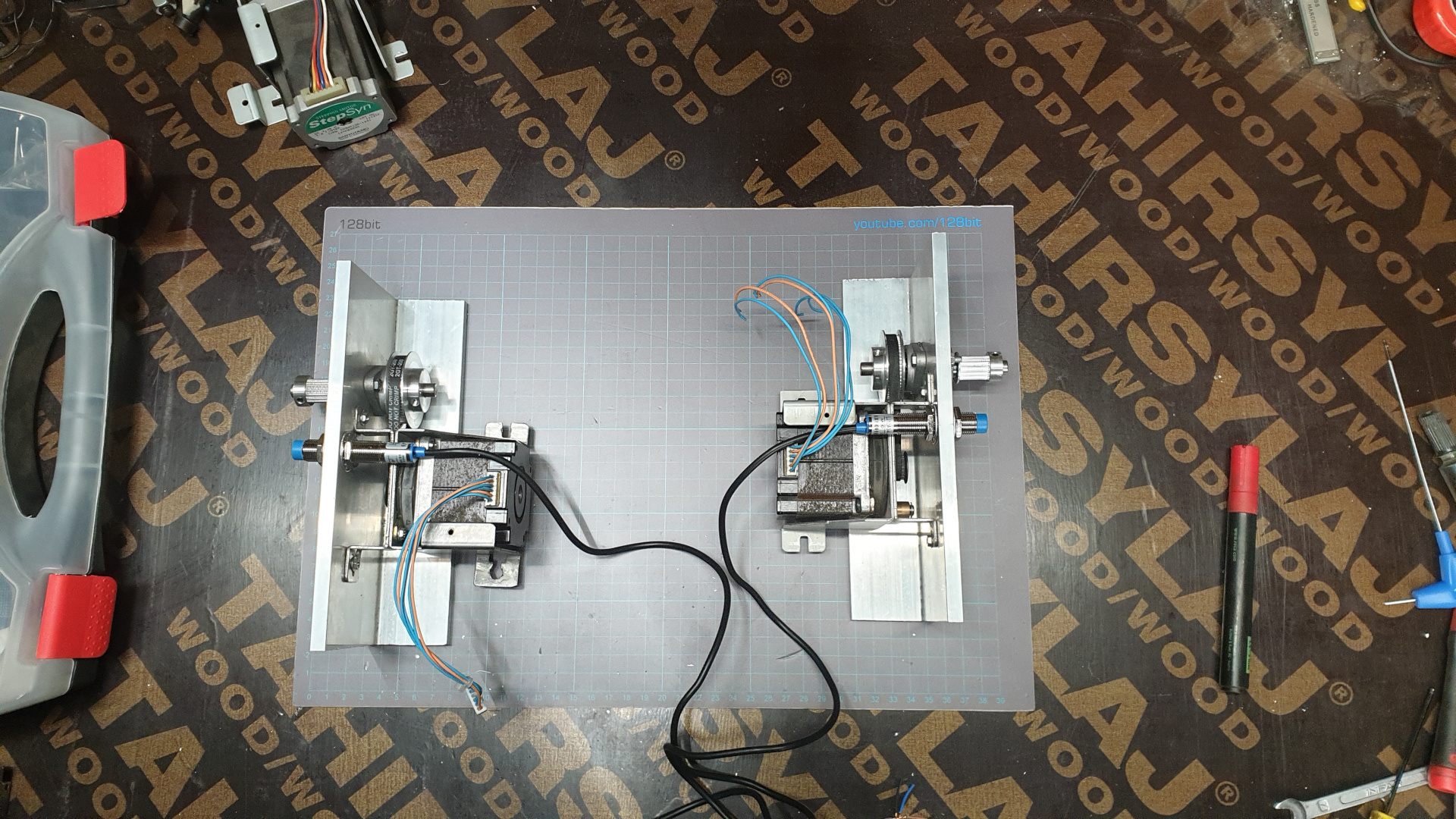

Finished gearing with the proximity sensor installed:

Another picture of the working side, missing an added 10mm thick 50X10mm alu part with idler bearings installed, out of bearings, so will do more pictures when i get to that:

-

On the small one i also installed the wide belt on the other side and sensors, will have to do some more cabling and sort the homing and limits for both sides tomorrow, see if i can pull that with just two sensors.

Regards,

Tom

L shaped alu profile 90X50mm, 8mm thick, 200mm long, 2 pieces, holes drilled for the shaft and bearing screws:

Two bearing with holder and two screws/nuts for each side:

GT2 60 teeth for the motor side, motor pulley is already on the motor, and T3 15 tooth pulley for the driving side, for 15mm wide belt.

Two Nema 23 stepper motors, used ones till they are mounted on the machine, then new ones double length:

Two 8mm shafts, both sides have two ground parts to prevent slipping:

Finished gearing with the proximity sensor installed:

Another picture of the working side, missing an added 10mm thick 50X10mm alu part with idler bearings installed, out of bearings, so will do more pictures when i get to that:

-

On the small one i also installed the wide belt on the other side and sensors, will have to do some more cabling and sort the homing and limits for both sides tomorrow, see if i can pull that with just two sensors.

Regards,

Tom

Attachments:

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Apr 2020 08:27 #165765

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

less is more with these machines i believe. lighter the better and you have it down to a science Tom. i had to watch the video twice just to figure out how you were driving the gantry  not only is it done to be light and just enough to do what it needs to but very cost effective in design. your a smart cookie

not only is it done to be light and just enough to do what it needs to but very cost effective in design. your a smart cookie

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

27 Apr 2020 08:34 #165767

by tommylight

And cost effective is a must here, labour got to be cheaper than in China, and knowledge is worth nothing here. Pretty much same as US !

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Yes it is when it comes to plasma cutting, the lighter the gantry/ head assembly, more acceleration = sharper corner without slowing down.less is more with these machines i believe. lighter the better and you have it down to a science Tom. i had to watch the video twice just to figure out how you were driving the gantry

not only is it done to be light and just enough to do what it needs to but very cost effective in design. your a smart cookie

And cost effective is a must here, labour got to be cheaper than in China, and knowledge is worth nothing here. Pretty much same as US !

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Apr 2020 09:59 #165774

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

to put things into perspective the gantry on the machine i am building is close to 300 lbs steppers work ok but not in the sense of the acceleration needed on the long axis moving the entire gantry. no good for plasma. the other two would be good but not as good as a gantry sized like yours. servo's might do it with adaptive tuning and electronic gearing but at a very steep cost curve to get there. i might be further ahead to do a smaller dedicated table to be honest. light and cheap in design to make up for added cost in electronic and plasma cutter.

don't get me wrong i like what i have built i see it doing well at milling and can add a wood router with no problems. in that respect i kept it realistic on the spindle and spent more on the frame work end of it. with any kind of milling you run out of rigidity before you max the spindle load out and if you want to have any chance of milling mild steel you better have the right speeds to run the tooling at and a frame that does something to negate vibrations steel and aluminum extrusion is not enough.

steel and aluminum extrusion is not enough.

don't get me wrong i like what i have built i see it doing well at milling and can add a wood router with no problems. in that respect i kept it realistic on the spindle and spent more on the frame work end of it. with any kind of milling you run out of rigidity before you max the spindle load out and if you want to have any chance of milling mild steel you better have the right speeds to run the tooling at and a frame that does something to negate vibrations

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

27 Apr 2020 10:16 #165775

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

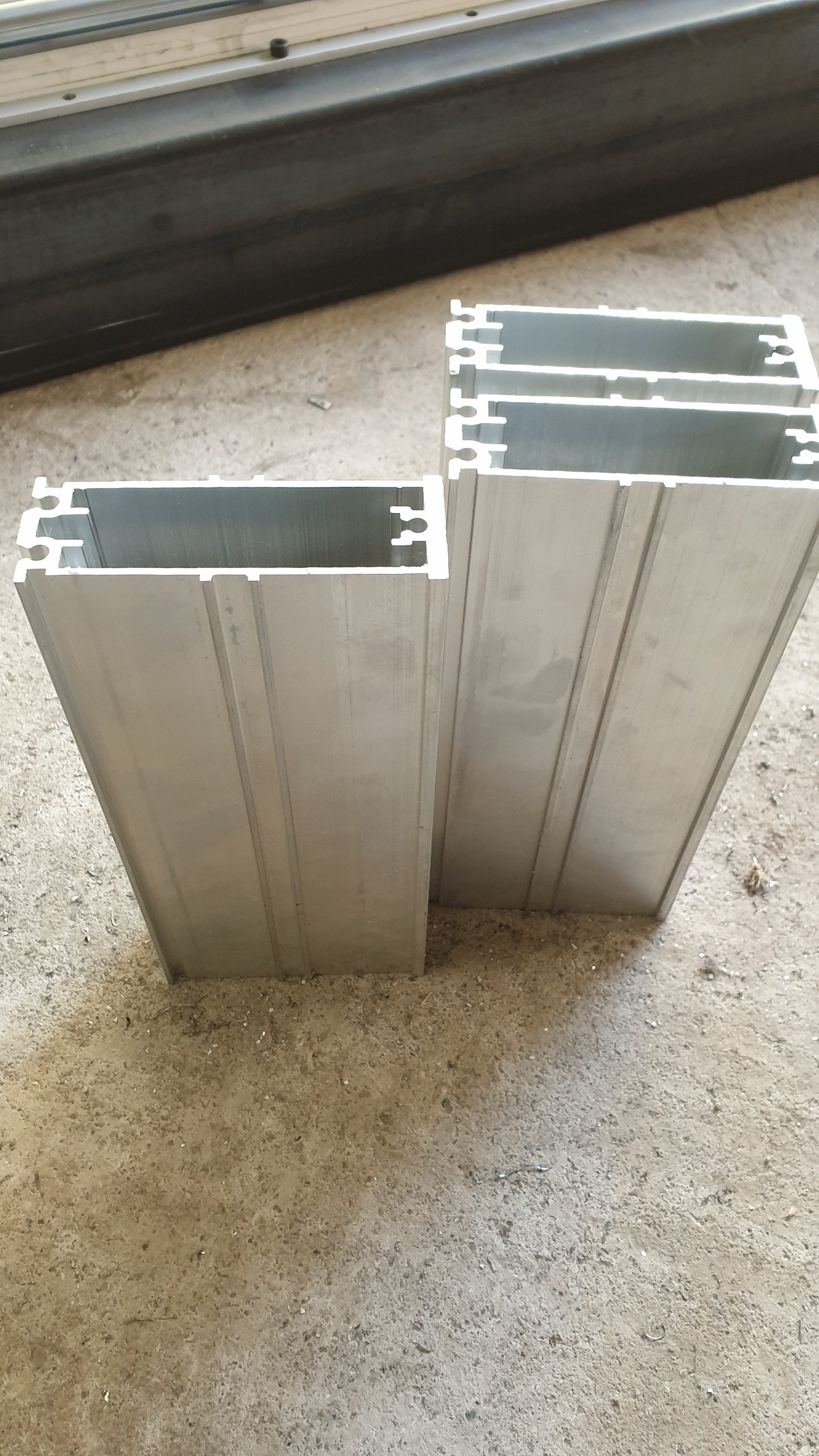

Tommy, what dimensions is that gantry extrusion. Is that what you are going to use?

You and Stefan have too much machinist in you thinking bigger is better.

Mine is heavier than Tommy's but with all motors and gantry ends, I think it came in at just over 30 kg (75 lb). A lot of that weight is the linear rails and gear rack. so only 100kg or 220 lb lighter than yours.With hindsight, I'm sure it only needs one linear rail, but Tommy's belts are way lighter again!

My rapids are about 21 m/min (825 in/min). I chuckled when Stefan asked if one of my videos had been speeded up

to put things into perspective the gantry on the machine i am building is close to 300 lbs.

You and Stefan have too much machinist in you thinking bigger is better.

Mine is heavier than Tommy's but with all motors and gantry ends, I think it came in at just over 30 kg (75 lb). A lot of that weight is the linear rails and gear rack. so only 100kg or 220 lb lighter than yours.With hindsight, I'm sure it only needs one linear rail, but Tommy's belts are way lighter again!

My rapids are about 21 m/min (825 in/min). I chuckled when Stefan asked if one of my videos had been speeded up

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

27 Apr 2020 10:25 #165776

by machinedude

Replied by machinedude on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

that's why Tommy is so smart driving with the belts. it cuts a lot weight out of the machine and makes it do it's job that much better. very clever without a doubt

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

27 Apr 2020 10:34 #165778

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

it just reinforces two things.

1. Routers and Plasma's have totally different design parameters. Dual purpose machines don't work out well.

2. Velocity and Acceleration is King for plasma cutting.

1. Routers and Plasma's have totally different design parameters. Dual purpose machines don't work out well.

2. Velocity and Acceleration is King for plasma cutting.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

27 Apr 2020 10:52 #165786

by tommylight

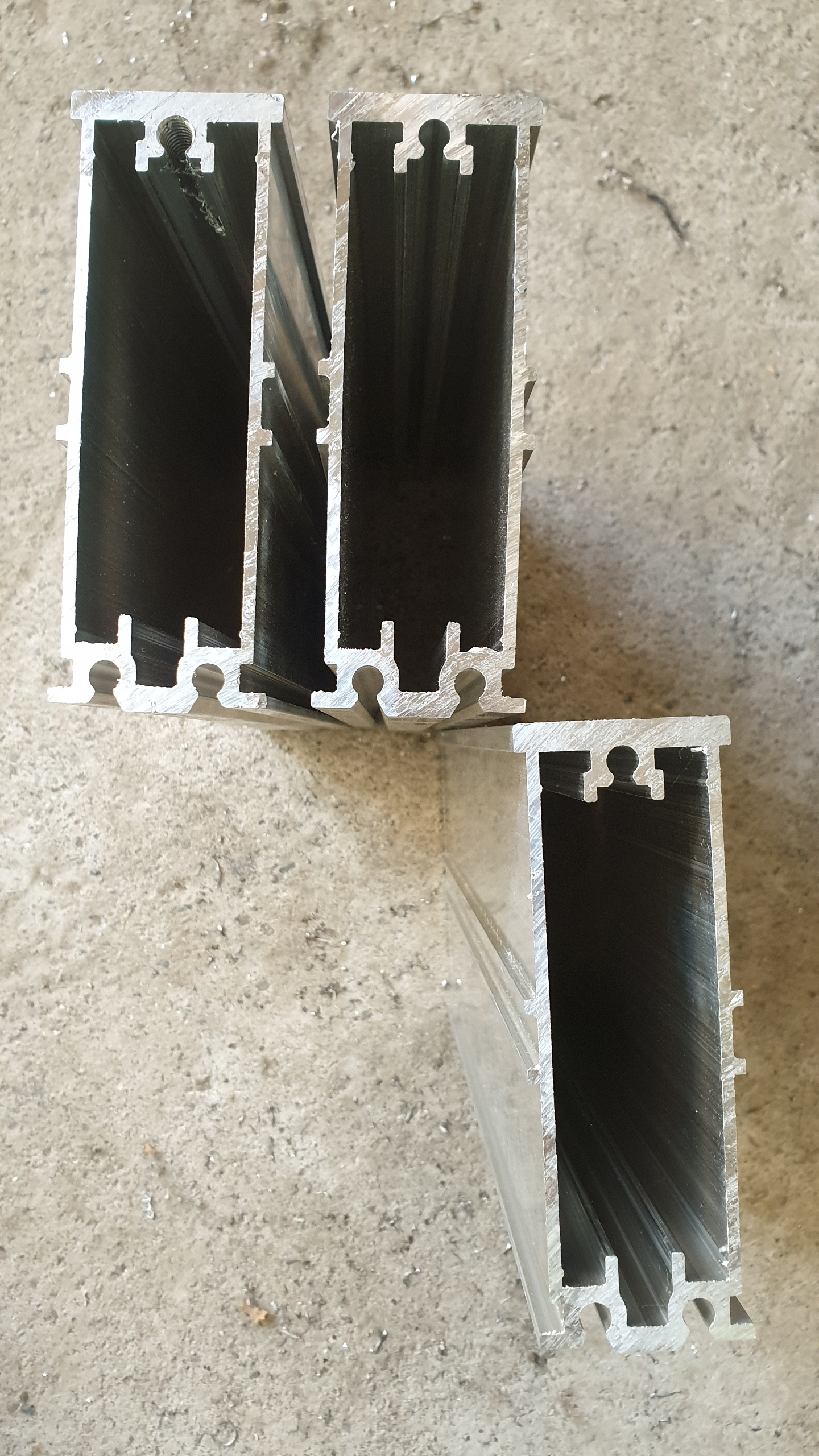

if i ever get them in the lengths i need, they are 128X44mm, thin walls at 2.5mm and thick ones at 6mm, so at 210 and 270cm lengths should be plenty strong.

BTW i got the big guns out getting ready to do some damage! I mean the big Lam Technologies drives.

Replied by tommylight on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

That is Bosch 45X45mm, and no i am not using that for the gantry, i will be using this:Tommy, what dimensions is that gantry extrusion. Is that what you are going to use?

if i ever get them in the lengths i need, they are 128X44mm, thin walls at 2.5mm and thick ones at 6mm, so at 210 and 270cm lengths should be plenty strong.

BTW i got the big guns out getting ready to do some damage! I mean the big Lam Technologies drives.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11726

- Thank you received: 3968

27 Apr 2020 11:05 #165794

by rodw

Replied by rodw on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

cool, I used 80x40mm RHS. I think the wall was 4mm, but it could have been 3mm.

And hurry up ans slam the Lams. I wanna see them fly.

And hurry up ans slam the Lams. I wanna see them fly.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

27 Apr 2020 11:13 #165797

by bbsr_5a

Replied by bbsr_5a on topic 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

why the expensive AL profiles not a cheep Square steelbody 3mm wall 2x2"

Please Log in or Create an account to join the conversation.

- Other Stuff

- Show Your Stuff

- 2+2+3 More Plasma builds, double the joy ! 3X2M and 2.5X1.5M cnc plasma build.

Time to create page: 0.304 seconds