Puma 560 simulation using pumakins

- andypugh

-

- Offline

- Moderator

-

- Posts: 19773

- Thank you received: 4601

When I do straight moves in the x- or y- direction the Puma in the simulation is doing a straight move and my Puma is slightly deviating from a straight line.

This probably indicates that the arm lengths of your robot are not _exactly_ the same as those in the kinematics and in the Vismach model.

Have you actually set the arm lengths in the HAL file? You set these as D2 and D4.

www.linuxcnc.org/docs/2.7/html/man/man9/kins.9.html

Please Log in or Create an account to join the conversation.

- jstoquica

-

- Offline

- Premium Member

-

- Posts: 117

- Thank you received: 8

I had similar error, with the X and Y axis, but my kinematics parameters are different, the homogeneous equations too. My solution was set "home" values for some axis and the vismach simulation was done.

In your case, I think that the values of DH parameters are different that original PUMA 560, because are different models. Look at the hal file and compare the values. The original parameters for PUMA 560 used at simulation are in the next site:

www.electronicsam.com/images/puma/pumaarm.jpg

Regards.

Please Log in or Create an account to join the conversation.

- robottom

- Offline

- Senior Member

-

- Posts: 53

- Thank you received: 4

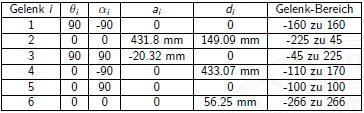

thanks for your replies. I did a rough measurement of my arms dimension and they seems to fit with the well known DH parameters for the PUMA found in the web.

Also my setting for the encoder and the gear resolution seems to be o.k. Still I have a deviation to what is displayed in the axis gui.

There is one strange thing I don't understand: In the DH parameter there is a A3 -20.32mm that shows that the axis for J2 and J3 are not on the same level if the J2 is horizontal but a 20mm difference. What is (at the first glance) also in all my Puma arms. But when I have the J2 horizontal and the J3 vertical and measure the distance of the base to the TCP there is not the x position as the display in axis gui. It seems that the kinematics is calculating 431.8mm-20-32mm for X= 411,48mm but the A3 seems to be a deviation in the Z-orientation when the J2 is horizontal and not in the X-direction so it should not have an influence on the X at this setup (J2 horizontal and J3 vertical) but infact the genserkins is comming up with this X-value for the calculation while in real world the puma arm is at X of 431mm (or even higher but this might be because of my measurement tolorances).

Maybe my Theta is not exactly the same in the DH parameter as they are in my Puma start configuartion of the test (I'm using the same position of joints as displayed in the simulation).

Any thoughts on that.

Many thanks!

Please Log in or Create an account to join the conversation.

- robottom

- Offline

- Senior Member

-

- Posts: 53

- Thank you received: 4

The configuration that works is with a A3 on 0 instead of -20.32mm. What was also wrong was the Alpha(i) what I put in as it originally came with the genserkins setup and not like the table below.

Maybe I did not fully understand the setting and that's why I was running a wrong config but still the A3 I do not understand. For me it looks like the A3 would be needed from design of the robot (Z3 does not seems to be on the same level as Z4).

Nevertheless it works now and I can continue my work.

Thanks for all your help.

Thomas

Please Log in or Create an account to join the conversation.

- Askjerry

-

- Offline

- Elite Member

-

- Posts: 237

- Thank you received: 30

So you were able to connect 6 Geckodrives (servo type) to the motors and read the original encoders... or did you need to replace the encoders?

Also... if you would make an ARCHIVE or ZIP of your entire CONFIGS directory and post it here... that would be EXTREMELY helpful for myself and anyone else trying to revive these old machines. If I can pick up a second machine from a friend (no controller) then I will see about doing an immediate retrofit. If we do... I'll be sure to make a series of how-to videos and have it on my web page.

Thanks,

Jerry

Please Log in or Create an account to join the conversation.

- jstoquica

-

- Offline

- Premium Member

-

- Posts: 117

- Thank you received: 8

Actually, I am developing a retrofitting project.

So you were able to connect 6 Geckodrives (servo type) to the motors and read the original encoders... or did you need to replace the encoders?

The best way is replace the original enconders. The basic answer is because the original technology is analog and the integration with digital technology (actual) will increase the investment resources.

I am updating my blog, when is ready I will post it.

Regards.

Please Log in or Create an account to join the conversation.

- robottom

- Offline

- Senior Member

-

- Posts: 53

- Thank you received: 4

sure I'm still using the old encoders. Replacing them would be too costly. It is a minimum cost project.

If you are using Gekodrives or the UHU drives I'm using then you anyhow have only the A/B signal of the encoder connected (no I- or analog potis connected) - I'm talking about the STEP/DIR Geko (G320X).This means there is currently no automated homing/absolute positioning when starting the maschine.

Sure no problem to upload the current LinuxCNC config (I can do this in the evening). If you want to use other Geko's (servo type not the STEP/DIR type - not sure) then the setup is for sure different. Also the JT2 setup will be different since the brown PUMA has different gear resolutions. But should be easy to adapt.

@jstoquica: what is the setup you would are currently building up?

Do you know any retailer for the single rectangle connectors of the older PUMA's? Not the round one's of the very old models but the models with the single rectangle ones (As far as I remeber 96 pins). My current Stäubli Puma has two very commonn HARTING connectors (sound & light equipment). They are easy to get but my other two PUMA arms (one from ~1988 and onther brown one) have both the single rectangle connector).

Best regards,

Thomas

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19773

- Thank you received: 4601

The best way is replace the original enconders. The basic answer is because the original technology is analog and the integration with digital technology (actual) will increase the investment resources..

If the original encoders are resolvers then there is a lot to be said for keeping them and using the Mesa 7i49. The advantage is that there is no need to home the machine then, the position feedback will always be absolute. The 7i49 isn't cheap, but then a full set of new encoders costs money too.

As someone else put it "Resolvers are better than encoders in every way except cost"

Please Log in or Create an account to join the conversation.

- jstoquica

-

- Offline

- Premium Member

-

- Posts: 117

- Thank you received: 8

When I wrote about replace the original encoders is because in many projects in Brazil like my one, the cost of retrofitting with new hardware control components only cost 11% of new robot price. It's a industrial robot.

robottom wrote:

what is the setup you would are currently building up?

It's a IRB6-S2(ASEA - ABB - 1970), you can see my post. It isn't updating yet.

plus.google.com/116960304375198732734/posts

HARTING connectors will be analyse later to decide if I can use or is better to replace for new one.

Regards.

Please Log in or Create an account to join the conversation.

- robottom

- Offline

- Senior Member

-

- Posts: 53

- Thank you received: 4

attached a first archiv file of my current setup. There is no optimization of velocity and no other optimizations. Just the setup to test if the genserkins works with the setup of the DH parameter set the basic setup of linuxcnc. After further tests and optimizations I can upload a new version.

Best regards, Thomas

Please Log in or Create an account to join the conversation.