Hurco BMC 20 Ultimax 3 Retrofit

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

27 Nov 2015 14:08 #65862

by Jake

Replied by Jake on topic Hurco Mill retrofit

I am going to pick up the machine on Thursday

It has Yasakawa CACR-SR10BB1BF-H servo drives in it. From what I have gathered these are analog servo drives.

If I went with Mesa, the 7i77 and 5i25 looks like it will do the trick.

It has Yasakawa CACR-SR10BB1BF-H servo drives in it. From what I have gathered these are analog servo drives.

If I went with Mesa, the 7i77 and 5i25 looks like it will do the trick.

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

04 Dec 2015 16:30 #66395

by Jake

Replied by Jake on topic Hurco Mill retrofit

Got the machine home. When it was powered yesterday it appears that the controller lost all the parameters. It's a ultimax3 control on there now. At least I have all the books, discs, drawings that are supposed to be with the machine. I guess it's time to start cleaning it up and figure out what I need hardware wise to get it going again.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21024

- Thank you received: 7163

06 Dec 2015 02:23 #66495

by tommylight

Replied by tommylight on topic Hurco Mill retrofit

Well several days ago i missed a chance to get my hands on a Hurco BMC30 with mechanical and electrical problems at a price of 6500 euro (around 7000$) but i found out it was sold for way less.

They seem like really nice machines and a nice project to turn to Linuxcnc, especially the ATC was a nice feature to have. Oh well, moving on.

Good luck with your project.

Tom

They seem like really nice machines and a nice project to turn to Linuxcnc, especially the ATC was a nice feature to have. Oh well, moving on.

Good luck with your project.

Tom

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

06 Dec 2015 02:31 #66496

by Jake

Replied by Jake on topic Hurco Mill retrofit

This machine looks pretty mechanically sound. I think its just the controls that are the problem child. The hour meter on it shows 35k hours. But I think these are power on hours, it does not look like it has that many hours on it. The Y box ways look like there in really good shape. I should have it off the trailer tomorrow, then I will start digging through the drawings and see if I can get a better grasp on what I need for conversion parts. This is marked as a 480V machine. There is a transformer hanging on the side of the machine. I am hoping that everything goes through the TX and I can just bypass it so I dont have to go buy a TX.

Have you done any retrofits with the ultimax control?

Have you done any retrofits with the ultimax control?

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

06 Dec 2015 20:09 #66520

by Jake

Replied by Jake on topic Hurco Mill retrofit

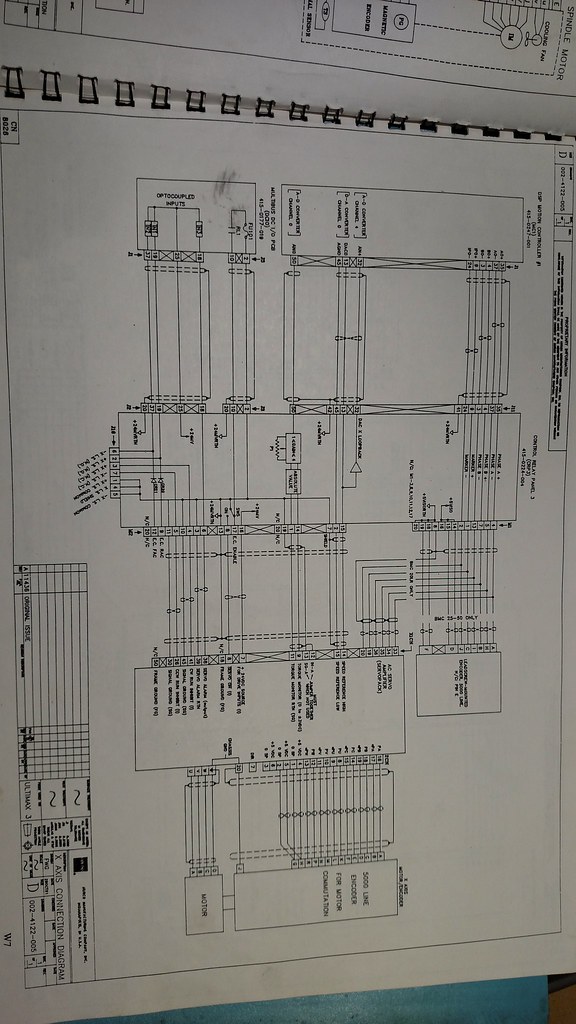

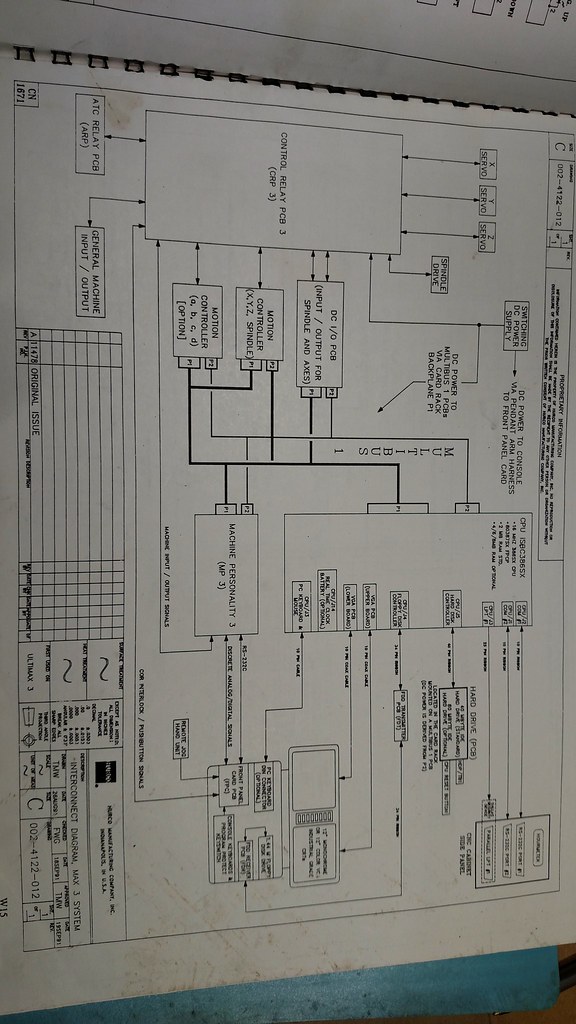

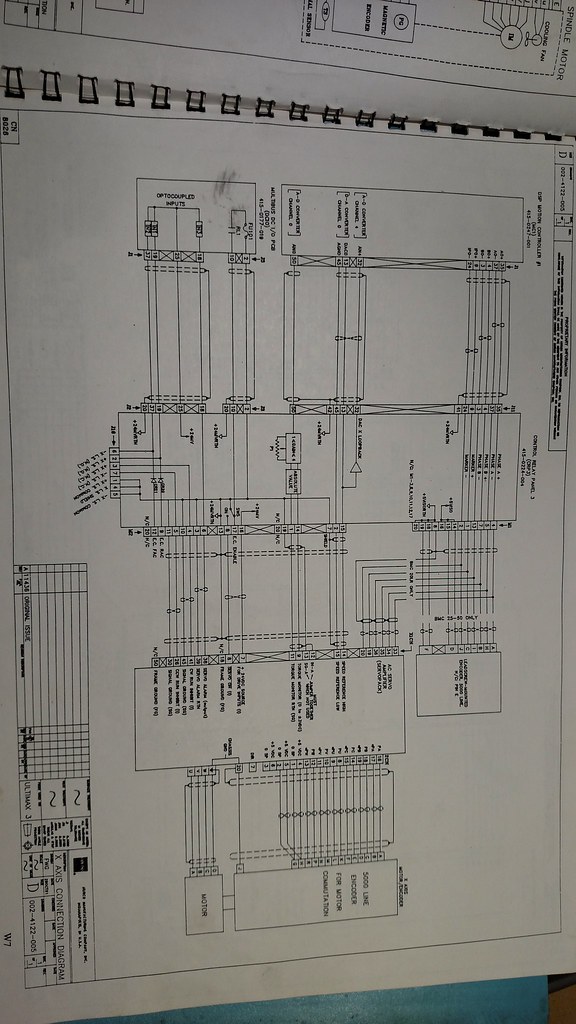

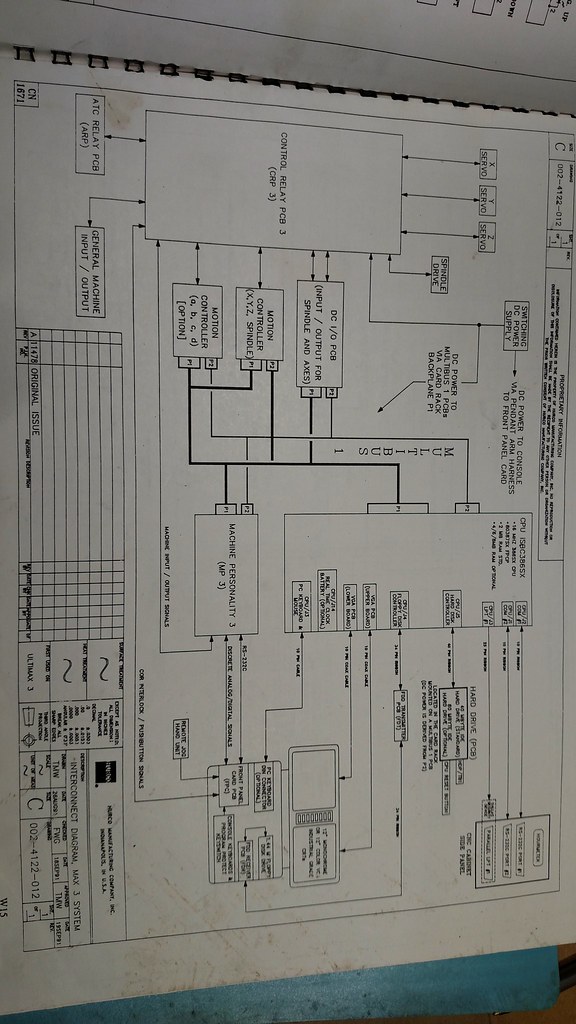

Here are some drawings for it,

From what I gather the CPU will be replaced with the new PC, The 7I77 will replace the DC I/O and the MP3 card and the 5I25 will interface between the PC and the 7I77. I went ahead and ordered the 5i25 and 7i77

Machine is sitting in the shop now. Just have to move my lathe and mill to get it where I want it.

It also looks like the pendant is just a mix of analog and digital signals so hopefully I will get that all to work also!

The encoders on the servos just feedback to the servo drives, while the axis encoders feedback for actual position

2015-12-05_09-23-25

by

Jake Freese

, on Flickr

2015-12-05_09-23-25

by

Jake Freese

, on Flickr

2015-12-05_09-23-13

by

Jake Freese

, on Flickr

2015-12-05_09-23-13

by

Jake Freese

, on Flickr

From what I gather the CPU will be replaced with the new PC, The 7I77 will replace the DC I/O and the MP3 card and the 5I25 will interface between the PC and the 7I77. I went ahead and ordered the 5i25 and 7i77

Machine is sitting in the shop now. Just have to move my lathe and mill to get it where I want it.

It also looks like the pendant is just a mix of analog and digital signals so hopefully I will get that all to work also!

The encoders on the servos just feedback to the servo drives, while the axis encoders feedback for actual position

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

15 Dec 2015 14:14 #67013

by Jake

Replied by Jake on topic Hurco BMC 20 Ultimax 3 Retrofit

Made a little headway!

LInuxCNC is installed on the PC, initial latency test is not looking good though. Half my video card fan is missing so I am going to go ahead and get a new video card for it, so I need to do some research on the most ideal video card for it.

Its all on a Dell Studio 540 I thought it was a Intel core 2 quad, with a ATI HD4350 video card. Hopefully hardware will be here at the end of the week! Onto the reducing latency battle.

When I would open LCNC I would click on the configuration adviser, I could choose many of the setups in the top section that were axis, or medium and it would open and work. But I I went down to "by configuration" and chose the Pico PPMC, it would throw out an error and quit.

LInuxCNC is installed on the PC, initial latency test is not looking good though. Half my video card fan is missing so I am going to go ahead and get a new video card for it, so I need to do some research on the most ideal video card for it.

Its all on a Dell Studio 540 I thought it was a Intel core 2 quad, with a ATI HD4350 video card. Hopefully hardware will be here at the end of the week! Onto the reducing latency battle.

When I would open LCNC I would click on the configuration adviser, I could choose many of the setups in the top section that were axis, or medium and it would open and work. But I I went down to "by configuration" and chose the Pico PPMC, it would throw out an error and quit.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19741

- Thank you received: 4579

15 Dec 2015 14:31 #67015

by andypugh

Probably failing to find either the EPP parallel port or a Pico PPMC connected to that parallel port.

Is Pico PPMC your chosen hardware interface?

Replied by andypugh on topic Hurco BMC 20 Ultimax 3 Retrofit

But I I went down to "by configuration" and chose the Pico PPMC, it would throw out an error and quit.

Probably failing to find either the EPP parallel port or a Pico PPMC connected to that parallel port.

Is Pico PPMC your chosen hardware interface?

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

15 Dec 2015 15:31 #67016

by Jake

Replied by Jake on topic Hurco BMC 20 Ultimax 3 Retrofit

Yeah I ended up with the Pico gear, I have a narrow window to get the majority of this knocked out. Jon was able to get the hardware enroute very quickly, the Pico PPMC seems more like a complete package, plus I like the card cage. I did not have the hardware connected yet, its supposed to be here late this week. That would explain why it was not happy with it.

I am running power to it, and cleaning this week. I am thinking about running a separate 240v single phase circuit to the control transformer so I can have control power all the time as the 3 phase is off a phase converter. Then I can have the controls powered without having the phase converter running.

I am running power to it, and cleaning this week. I am thinking about running a separate 240v single phase circuit to the control transformer so I can have control power all the time as the 3 phase is off a phase converter. Then I can have the controls powered without having the phase converter running.

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

20 Dec 2015 14:11 #67169

by Jake

Replied by Jake on topic Hurco BMC 20 Ultimax 3 Retrofit

I have power and air to the machine now, I have been going through trying to see how I can interface with the CRP3 board to keep it, as it has all the relaying on it for coolant, tool changer, lube system....

Latency on the PC I was attempting to use looks like it may be a problem.

Dell Studio 540, Intel Core2 Quad Q9400 2.66 GHz

ATI HD3450 video card.

Servo 1021419, 173278

Base 52365, 27403

I disabled the onboard audio with no improvement. I am going to keep digging through the Wiki to see if there is something else I need to try, or if I need to look into another PC solution. From looking at the latency stats it seems as there is something with Dell machines and the servo max jitter, as many of them are very high or un-useable.

Latency on the PC I was attempting to use looks like it may be a problem.

Dell Studio 540, Intel Core2 Quad Q9400 2.66 GHz

ATI HD3450 video card.

Servo 1021419, 173278

Base 52365, 27403

I disabled the onboard audio with no improvement. I am going to keep digging through the Wiki to see if there is something else I need to try, or if I need to look into another PC solution. From looking at the latency stats it seems as there is something with Dell machines and the servo max jitter, as many of them are very high or un-useable.

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

23 Dec 2015 02:39 #67254

by Jake

Replied by Jake on topic Hurco BMC 20 Ultimax 3 Retrofit

I made some headway today!

Encoders are hooked up, I ended up pulling out all of the old control. I was hoping to use the control relay panel, but it's been repaired and or modified a couple times so it appeared that it was going to be a headache to deal with.

I'm going to get my analog servo signals hooked up, and see what else I need to get going to get basic motion.

How many of y'all are using the servo torque monitors or load meters? It appears mine are both analog signals.

There are some items items like orient complete, orient command, ( assuming these are associated with tool changes). It looks like it calls for the commands and confirms it's there.

The low speed winding select and winding select, I need to research the speed ranges to see when it's supposed to be where.

I'll need at least 1 more I/O board as there are 20 inputs I have found so far. 10 control contacts and 10 more current carrying contacts.

Encoders are hooked up, I ended up pulling out all of the old control. I was hoping to use the control relay panel, but it's been repaired and or modified a couple times so it appeared that it was going to be a headache to deal with.

I'm going to get my analog servo signals hooked up, and see what else I need to get going to get basic motion.

How many of y'all are using the servo torque monitors or load meters? It appears mine are both analog signals.

There are some items items like orient complete, orient command, ( assuming these are associated with tool changes). It looks like it calls for the commands and confirms it's there.

The low speed winding select and winding select, I need to research the speed ranges to see when it's supposed to be where.

I'll need at least 1 more I/O board as there are 20 inputs I have found so far. 10 control contacts and 10 more current carrying contacts.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.078 seconds