HURCO KMB-1 Control Update

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

02 Mar 2025 17:58 #323034

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Could this lack of response to the jog wheel motion be because there are no connections to the Axis halui in the file?

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

03 Mar 2025 09:07 #323073

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Just for the record the machine is homed, but actively changing axis.x.jog-counts moves nothing.

Are the published the mpg hals I have adopted for stepper motor systems, and not appropriate for my DC servo system?

Are the published the mpg hals I have adopted for stepper motor systems, and not appropriate for my DC servo system?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4649

- Thank you received: 2070

03 Mar 2025 09:28 #323076

by Aciera

Replied by Aciera on topic HURCO KMB-1 Control Update

jogging operation is independent of the type of motors used. Have you actually confirmed in halshow that these pins are set correctly?

axis.L.jog-scale

axis.L.jog-enable

axis.L.jog-counts

axis.L.jog-scale

axis.L.jog-enable

axis.L.jog-counts

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

03 Mar 2025 10:21 #323082

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Yes, I have checked them over and over, so may have developed a blindness.

I have my rapid plus and minus buttons connected to the scale inputs.

the input pin for each one goes yellow when pressed.

axis.L.jog-scale is zero when no buttons pressed, and 1e5 for left button and 1e6 when right button is held in.

axis.L.jog-enable each of the three axes lights go yellow when the appropriate button is pressed

axis.L.jog-counts large numbers go up and down on all three axes as the wheel is turned

I have my rapid plus and minus buttons connected to the scale inputs.

the input pin for each one goes yellow when pressed.

axis.L.jog-scale is zero when no buttons pressed, and 1e5 for left button and 1e6 when right button is held in.

axis.L.jog-enable each of the three axes lights go yellow when the appropriate button is pressed

axis.L.jog-counts large numbers go up and down on all three axes as the wheel is turned

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

03 Mar 2025 14:27 #323088

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

checked that motion.is-all-homed is TRUE , then had one last prod of the buttons, and the axis does jog on the wheel.

Only if both my plus and minus buttons are pressed together.

With both pressed the scale is .0001

What I really want to do is with those buttons is to duplicate what the rapid plus and minus do on the Axis gui

Only if both my plus and minus buttons are pressed together.

With both pressed the scale is .0001

What I really want to do is with those buttons is to duplicate what the rapid plus and minus do on the Axis gui

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

05 Mar 2025 07:36 - 05 Mar 2025 07:37 #323243

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

I have jogging setup as well as I can now.

Had to NOT the two switch inputs that control rate, and also enable the quadrature counting as well as adjust the mux parameters.

What I notice now is that I have to be very careful turning the wheel.

If too fast, the counts are missed, and if I get the speed of the wheel just right the axis moves in reverse.

With the original 1982 control, this wasn't an issue.

I'm going to scope the signals to ensure they are clean, but wondered if there is a max counting rate on the 7i73 that I am exceeding?

Thanks

Had to NOT the two switch inputs that control rate, and also enable the quadrature counting as well as adjust the mux parameters.

What I notice now is that I have to be very careful turning the wheel.

If too fast, the counts are missed, and if I get the speed of the wheel just right the axis moves in reverse.

With the original 1982 control, this wasn't an issue.

I'm going to scope the signals to ensure they are clean, but wondered if there is a max counting rate on the 7i73 that I am exceeding?

Thanks

Last edit: 05 Mar 2025 07:37 by NT4Boy.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

05 Mar 2025 15:33 - 05 Mar 2025 15:34 #323279

by PCW

Replied by PCW on topic HURCO KMB-1 Control Update

Your hal file shows a software encoder rather than the 7I73's encoder,

A software encoder sampled at the servo thread rate will limit you to less than

1000 counts per second. You would need to use the 7I73s encoder counter to go

faster. From the 7I73 manual:

"The 7I73 can track encoder inputs up to a 50 KHz maximum count rate (4X modes).

Maximum count rate is 12.5 KHz in 1X modes and 25 KHz in 2X modes. These maximum

count rates will be reduced by quadrature distortion (deviation from 90 degree phase

difference between A and B ) so practical maximum count rates are normally somewhat

lower.

A software encoder sampled at the servo thread rate will limit you to less than

1000 counts per second. You would need to use the 7I73s encoder counter to go

faster. From the 7I73 manual:

"The 7I73 can track encoder inputs up to a 50 KHz maximum count rate (4X modes).

Maximum count rate is 12.5 KHz in 1X modes and 25 KHz in 2X modes. These maximum

count rates will be reduced by quadrature distortion (deviation from 90 degree phase

difference between A and B ) so practical maximum count rates are normally somewhat

lower.

Last edit: 05 Mar 2025 15:34 by PCW.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

05 Mar 2025 18:40 - 05 Mar 2025 18:40 #323300

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Oh dear..My poor old brain.

So, the MPG is connected to the correct pins, but the input designation I should be using is perhaps hm2_7i92.0.7i73.0.2.enc0.count to get access to the high speed values?

So take the encoder count stuff out of the hal thread and instead couple

net mpg-out ilowpass.0.in <= hm2_7i92.0.7i73.0.2.enc0.count

So, the MPG is connected to the correct pins, but the input designation I should be using is perhaps hm2_7i92.0.7i73.0.2.enc0.count to get access to the high speed values?

So take the encoder count stuff out of the hal thread and instead couple

net mpg-out ilowpass.0.in <= hm2_7i92.0.7i73.0.2.enc0.count

Last edit: 05 Mar 2025 18:40 by NT4Boy.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17630

- Thank you received: 5158

05 Mar 2025 18:42 #323301

by PCW

Replied by PCW on topic HURCO KMB-1 Control Update

Yes, you don't need the hal encoder comp at all and unless you have a base thread

(not practical with an Ethernet connected device), the hal component will be quite slow.

(not practical with an Ethernet connected device), the hal component will be quite slow.

The following user(s) said Thank You: NT4Boy

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Mar 2025 08:49 - 13 Mar 2025 08:51 #323810

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Jogging all good now, so paying attention to getting the variable resistor potentiometers to control feedrate and spindle speed overrides.

This was complicated by the fact the Hurco has these pots internally fed with 5 volts, and I am reading the analogue voltage via 7i73 pins that tolerate 3.3volts max. However, addressed that with a resistor bridge. Then I want for the pot controls to also change the gui sliders on the Axis screen.

The attached postgui hal makes that all work, and by adjusting the scale figure can get the mid positions to align with 100%, near enough.

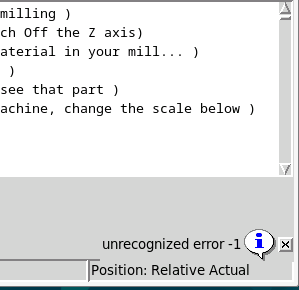

To get that right I have been stopping and starting the Axis gui, over and over without homing the machine and find that this "unrecognised error" message crops up sometimes, freezing the rate sliders. The Gui can stiil be shut down normally using the top right X , and generally on a restart, it works again but would like to know what the cause is.

Thanks

I have never seen this error before until I used the mult2 function in this hal.

This was complicated by the fact the Hurco has these pots internally fed with 5 volts, and I am reading the analogue voltage via 7i73 pins that tolerate 3.3volts max. However, addressed that with a resistor bridge. Then I want for the pot controls to also change the gui sliders on the Axis screen.

The attached postgui hal makes that all work, and by adjusting the scale figure can get the mid positions to align with 100%, near enough.

To get that right I have been stopping and starting the Axis gui, over and over without homing the machine and find that this "unrecognised error" message crops up sometimes, freezing the rate sliders. The Gui can stiil be shut down normally using the top right X , and generally on a restart, it works again but would like to know what the cause is.

Thanks

I have never seen this error before until I used the mult2 function in this hal.

Attachments:

Last edit: 13 Mar 2025 08:51 by NT4Boy.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.149 seconds