HURCO KMB-1 Control Update

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17654

- Thank you received: 5163

12 Jun 2025 18:14 - 12 Jun 2025 18:39 #330222

by PCW

Replied by PCW on topic HURCO KMB-1 Control Update

Sounds like the drive has a significant offset or there is some electrical issue

What RPM do you get from the drive at 0V?

I is not for tuning overshoot but to have a slow but unlimited feedback

You can try more I term ( until it oscillates then back off to say 25% ) but I think the

real problem is the offset.

(the P term by itself cannot bring the error to 0 because the P term needs

and error to have any effect)

All this to say, it sounds like there is an electrical issue or perhaps drive

parameter setup issue that needs to be addressed rather than patched

over in LinuxCNC.

What RPM do you get from the drive at 0V?

I is not for tuning overshoot but to have a slow but unlimited feedback

You can try more I term ( until it oscillates then back off to say 25% ) but I think the

real problem is the offset.

(the P term by itself cannot bring the error to 0 because the P term needs

and error to have any effect)

All this to say, it sounds like there is an electrical issue or perhaps drive

parameter setup issue that needs to be addressed rather than patched

over in LinuxCNC.

Last edit: 12 Jun 2025 18:39 by PCW.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

12 Jun 2025 18:25 #330224

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Attachments:

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

12 Jun 2025 18:27 #330225

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

I'm going to check into the belt tension. I know too tight howls, but too loose?

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Jun 2025 10:54 #330247

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Gates Belt Tension Calculator

Gates 'phone Frequency App

So from the type of belt, length, number of teeth on the pulley, motor speed and power etc, Gates recommend tensioning to a twang frequency between 39-41Hz.

At this tension, the thing sings pretty loud with the covers off, but is far less sensitive to oscillations. Have P of 0.45, and I increased to 0.015

With output scale at 4500.

Get

cmd actual

300 400

400 420

500 500

600 600

700 700

1000 1000

1500 1400

2000 1900

2500 2400

3000 2800

3500 3300

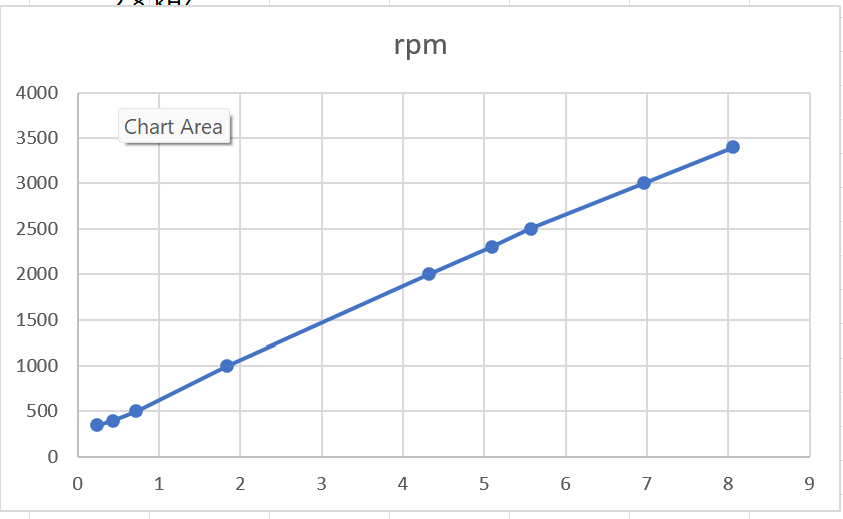

Have also now looked at the motor speed with zero volts to the VFD and its 250 (Hurco book says 150, but for now its in the ball park).

The rest of the low end volts looks like this.

Gates 'phone Frequency App

So from the type of belt, length, number of teeth on the pulley, motor speed and power etc, Gates recommend tensioning to a twang frequency between 39-41Hz.

At this tension, the thing sings pretty loud with the covers off, but is far less sensitive to oscillations. Have P of 0.45, and I increased to 0.015

With output scale at 4500.

Get

cmd actual

300 400

400 420

500 500

600 600

700 700

1000 1000

1500 1400

2000 1900

2500 2400

3000 2800

3500 3300

Have also now looked at the motor speed with zero volts to the VFD and its 250 (Hurco book says 150, but for now its in the ball park).

The rest of the low end volts looks like this.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Jun 2025 10:58 #330248

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Sorry, failed to sort out the links carrying on into the text.

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Jun 2025 15:45 #330254

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

So, armed with a working spindle encoder, I've tried my luck with a rigid tapping cycle.

Spindle runs, and the code gets to the G33 line, but after the spindle advances down a little, motion and the spindle stop without any error message.

Looking here Docs/Examples/Spindle section 6.1 I am assuming that I don't have to add yet another encoder to the hal, but can use this working one?

I did test the spindle running at around 500rpm, and simply changing direction, and the system manually happily does that.

So, not sure where to look.

Thanks

Complete programme below in case something is wrong.

%

(RIGID TAP M8X1.25)

(T1 D=8. CR=0. - ZMIN=-11. - RIGHT HAND TAP)

N10 G90 G94 G17 G91.1

N15 G21

N20 G53 G0 Z0.

(DRILL1)

N25 T1 M6

N30 S500 M3

N35 G17 G90 G94

N40 G54

N45 M8

N50 G0 X0. Y0.

N55 G43 Z15. H1

N60 G0 Z5.

N65 G33.1 Z-11. K1.25

N70 G0 Z5.

N75 X0. Y0. Z15.

N80 M5

N85 M9

N90 G53 G0 Z0.

N95 M30

%

Spindle runs, and the code gets to the G33 line, but after the spindle advances down a little, motion and the spindle stop without any error message.

Looking here Docs/Examples/Spindle section 6.1 I am assuming that I don't have to add yet another encoder to the hal, but can use this working one?

I did test the spindle running at around 500rpm, and simply changing direction, and the system manually happily does that.

So, not sure where to look.

Thanks

Complete programme below in case something is wrong.

%

(RIGID TAP M8X1.25)

(T1 D=8. CR=0. - ZMIN=-11. - RIGHT HAND TAP)

N10 G90 G94 G17 G91.1

N15 G21

N20 G53 G0 Z0.

(DRILL1)

N25 T1 M6

N30 S500 M3

N35 G17 G90 G94

N40 G54

N45 M8

N50 G0 X0. Y0.

N55 G43 Z15. H1

N60 G0 Z5.

N65 G33.1 Z-11. K1.25

N70 G0 Z5.

N75 X0. Y0. Z15.

N80 M5

N85 M9

N90 G53 G0 Z0.

N95 M30

%

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

13 Jun 2025 15:58 #330255

by tommylight

Replied by tommylight on topic HURCO KMB-1 Control Update

Not my forte, but probably missing "spindle at speed" signal in hal ???

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Jun 2025 17:08 #330256

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Thanks Tommy,

Looks like my constant playing with speeds up and down the range has had something over as it won't now swap directions without the spindle enable relay dropping out.

Worked this morning.

Poor old thing. It, not me, or maybe me as well.

Looks like my constant playing with speeds up and down the range has had something over as it won't now swap directions without the spindle enable relay dropping out.

Worked this morning.

Poor old thing. It, not me, or maybe me as well.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

13 Jun 2025 20:48 #330261

by tommylight

Replied by tommylight on topic HURCO KMB-1 Control Update

What's the current status?

Please Log in or Create an account to join the conversation.

- NT4Boy

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 12

13 Jun 2025 21:26 #330262

by NT4Boy

Replied by NT4Boy on topic HURCO KMB-1 Control Update

Sorry, dead of night here.

Last test is that the VFD shear pin circuit is being tripped, oddly could coincide with the tensioned belt.

Need to sleep on it and investigate further.

Could be I need to introduce the limit2 and ramp these decels, assuming that limit2 does accels and decels?

Thanks for worrying.

Last test is that the VFD shear pin circuit is being tripped, oddly could coincide with the tensioned belt.

Need to sleep on it and investigate further.

Could be I need to introduce the limit2 and ramp these decels, assuming that limit2 does accels and decels?

Thanks for worrying.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 1.090 seconds