LinuxCNC + Orange Pi (allwincnc)

- envyvan

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 3

11 Jul 2022 03:26 #247051

by envyvan

Replied by envyvan on topic LinuxCNC + Orange Pi (allwincnc)

Just an update - while playing around with spindle I found that, I am missing spindle-index signal (my encoder does not have this functionality). I've add a simple patch to arisc.c driver (for H3) that can emulate index.

This patch just zeroes position and reports back to hal that index arrived - I am NOT SURE if this is right, but it seems to work for me. Please check it!!!

That was completely wrong. DO NOT use simulate_index.patch, use simulate_index_v1.patch file!!

Now simulated index always waits for next full revolution before clearing spindle position and sending back index signal to HAL. In this way our virtual index fires at the position that spindle was at linuxcnc startup.

Patch file and HAL config are attached here. To use simulated index just set "arisc.encoder.X.simulate-index" parameter to 1, then connect spindle.X.index-enable in normal way.

Please Log in or Create an account to join the conversation.

- xenon-alien

-

- Offline

- Premium Member

-

Less

More

- Posts: 151

- Thank you received: 4

14 Aug 2022 18:30 - 14 Aug 2022 19:48 #249732

by xenon-alien

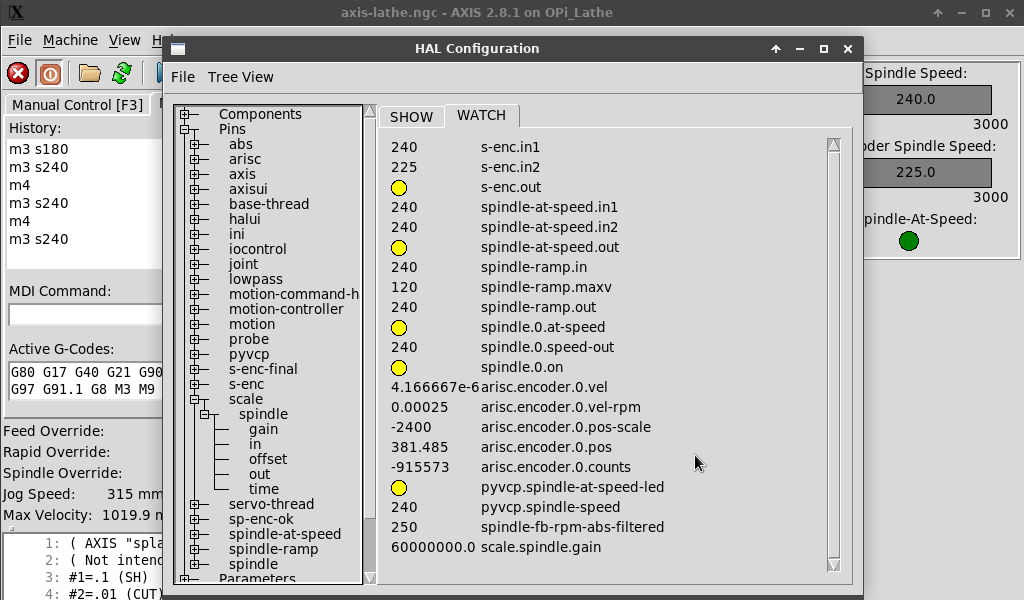

Can you look at the encoder velocity?

I have a configuration for a lathe, but i need to scale RPS to 60 000 000 to have a "correct" spindle-at-speed. and the RPM change range only 25 RPM on the encoder. If I command 240 RPM the encoder velocity is showing 225, or 250 (if speed up, the next will be 275, 300, 325 and so on)

In % to reach the spindle at speed I need to change the value from 1.01 (to be in 1% of error) to 1.5 (50% error) in the .hal to get green light. On slower speed is worst... (I will use a servo drive encoder output - 13 bit = 8192 in LCNC scale)

Is it possible to correct it some how?

Replied by xenon-alien on topic LinuxCNC + Orange Pi (allwincnc)

Hello!Sorry, I'm not working with git much - after a few tutorials I'm still not sure how to create a valid pull request. Please check the patch files from this message.

I've added new output to HAL (period_ticks) for testing the ARISC code. It is pin A period in raw timer ticks. Then the hal driver calculates velocity from period output, until about 110kHz when it switches back to frequency. Of course this is rather poor, and we should use method described by PCW. Anyway this code seems to work orangePi H3 (the only board I have).

Can you look at the encoder velocity?

I have a configuration for a lathe, but i need to scale RPS to 60 000 000 to have a "correct" spindle-at-speed. and the RPM change range only 25 RPM on the encoder. If I command 240 RPM the encoder velocity is showing 225, or 250 (if speed up, the next will be 275, 300, 325 and so on)

In % to reach the spindle at speed I need to change the value from 1.01 (to be in 1% of error) to 1.5 (50% error) in the .hal to get green light. On slower speed is worst... (I will use a servo drive encoder output - 13 bit = 8192 in LCNC scale)

Is it possible to correct it some how?

Attachments:

Last edit: 14 Aug 2022 19:48 by xenon-alien.

Please Log in or Create an account to join the conversation.

- yi2580

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 3

30 Aug 2022 02:57 #250744

by yi2580

Replied by yi2580 on topic LinuxCNC + Orange Pi (allwincnc)

Hello, seniors,

I have an OPI now, but I feel that its GPIO interface is not enough for the things I want to control, such as the five axes. It may not be enough to add some limit return and stop switches and handwheels. So I want to ask if OPI supports etehrcat? I have several EtherCAT drives. I don't know if OPI supports them. I used to use x86 to control drives with Linux CNC and IgH EtherCAT.

If someone has done it, or can give me some help, I will be very grateful.

I have an OPI now, but I feel that its GPIO interface is not enough for the things I want to control, such as the five axes. It may not be enough to add some limit return and stop switches and handwheels. So I want to ask if OPI supports etehrcat? I have several EtherCAT drives. I don't know if OPI supports them. I used to use x86 to control drives with Linux CNC and IgH EtherCAT.

If someone has done it, or can give me some help, I will be very grateful.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

30 Aug 2022 21:48 - 30 Aug 2022 21:48 #250802

by Bari

Replied by Bari on topic LinuxCNC + Orange Pi (allwincnc)

The original maintainer of this project has stopped development. You are free to fork it and add features like EtherCAT.

Last edit: 30 Aug 2022 21:48 by Bari.

Please Log in or Create an account to join the conversation.

- yi2580

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 3

31 Aug 2022 00:39 - 31 Aug 2022 00:42 #250820

by yi2580

Replied by yi2580 on topic LinuxCNC + Orange Pi (allwincnc)

What a pity! Can you give me some suggestions on using this board for development? It's my first time to use this board. I hope I can get some help. I now have an RK3399 board, which is Orange Pi 4B. I don't know if he is feasible.

Last edit: 31 Aug 2022 00:42 by yi2580.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

31 Aug 2022 00:50 - 31 Aug 2022 00:54 #250822

by Bari

Replied by Bari on topic LinuxCNC + Orange Pi (allwincnc)

opensource.rock-chips.com/wiki_RK3399

forum.linuxcnc.org/18-computer/46077-pot...ngle-board-computers

You just need developer/s that are familiar with u-boot, ARM Linux, LCNC and how to program the Cortex M0 microcontrollers.

I think it's a great ARM SOC for running LCNC with a high speed integrated stepgen, and the boards are available and only ~$60ea. It's a few week project for someone that knows what they are doing. It also has a GPU capable of running a HD display at 30fps.

forum.linuxcnc.org/18-computer/46077-pot...ngle-board-computers

You just need developer/s that are familiar with u-boot, ARM Linux, LCNC and how to program the Cortex M0 microcontrollers.

I think it's a great ARM SOC for running LCNC with a high speed integrated stepgen, and the boards are available and only ~$60ea. It's a few week project for someone that knows what they are doing. It also has a GPU capable of running a HD display at 30fps.

Last edit: 31 Aug 2022 00:54 by Bari.

Please Log in or Create an account to join the conversation.

- yi2580

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 3

31 Aug 2022 01:16 #250825

by yi2580

Replied by yi2580 on topic LinuxCNC + Orange Pi (allwincnc)

OK, thank you very much for your suggestions. I don't know how to start. For example, how can I install a real-time kernel on my system to run Linux CNC? I also have an H3 board here. I have his system image. All Linux CNC has been installed and can be used, but it does not meet my requirements. I need a lot of IO ports, which seems to be a little small, so I consider using EtherCAT to realize it. I don't know whether it is feasible.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

31 Aug 2022 01:32 #250828

by Bari

Replied by Bari on topic LinuxCNC + Orange Pi (allwincnc)

The most simple way is to use Mesa FPGA cards with a RK3399 boards over Ethernet. How to build RT ARM Linux kernels for RK3399 is beyond the scope of this forum.

EtherCAT discussions are at: www.forum.linuxcnc.org/ethercat

EtherCAT discussions are at: www.forum.linuxcnc.org/ethercat

Please Log in or Create an account to join the conversation.

- yi2580

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 3

31 Aug 2022 01:39 #250830

by yi2580

Replied by yi2580 on topic LinuxCNC + Orange Pi (allwincnc)

I would like to ask how you installed the RT real-time kernel when using H3 card before? Can you give me some suggestions? I will be very grateful

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 635

- Thank you received: 232

31 Aug 2022 01:43 #250831

by Bari

Replied by Bari on topic LinuxCNC + Orange Pi (allwincnc)

I think this project started out using Armbian and there was a filesystem image that you could just dd onto an SD-card.

allwincnc.github.io/install.html

allwincnc.github.io/install.html

Please Log in or Create an account to join the conversation.

Time to create page: 0.198 seconds