Pimping the mini-lathe

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

07 Aug 2020 13:29 #177617

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Do you create you own bit files for Mesa hardware? I was just rewatching Talla83's excellent (but german language) tutorial on how to create you own bit files.

On the one hand it looks reasonably simple, but seeing as I am a really sloppy coder (I again locked up Linuxcnc in endless loops yesterday by looping to infinity....twice) I would be concerned about bricking my 7i96 dicking around with this.

Mark

On the one hand it looks reasonably simple, but seeing as I am a really sloppy coder (I again locked up Linuxcnc in endless loops yesterday by looping to infinity....twice) I would be concerned about bricking my 7i96 dicking around with this.

Mark

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

07 Aug 2020 13:38 #177619

by tommylight

Replied by tommylight on topic Pimping the mini-lathe

No i do not, i did try that a while back (quite a while) and got tired of waiting to download a gazillion of megabytes of software, and while i was at waiting for it PCW had already made what i needed. He has a nasty habit of making custom firmware inside a day for whatever i might need and no matter how silly my requests are !  The best support on planet earth !

The best support on planet earth !

I do not know if 7i96 has dual firmwares as most of the Mesa boards do, so here we go :

PCW, helppppp !

I do not know if 7i96 has dual firmwares as most of the Mesa boards do, so here we go :

PCW, helppppp !

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17626

- Thank you received: 5157

07 Aug 2020 14:03 #177621

by PCW

Replied by PCW on topic Pimping the mini-lathe

If you are concerned about bricking the 7I96, you can try new firmware by loading it into

the fallback area of the EEPROM:

mesaflash --device 7i96 --addr xx.xx.xx.xx --write test.bit --fallback

and then load the FPGA from the fallback area of the EEPROM:

mesaflash --device 7i96 --addr xx.xx.xx.xx --reload --fallback

If this fails, you can just power cycle the card and reload the user configuration

As far as MPGs go, running a software encoder on the isolated inputs is one way

but will only work with 5V MPG signals if you have the input common at ground

If you are running LinuxCNC 2.9 you can also get hardware MPG encoders on the isolated

inputs using the inm firmware (the inm firmware also has hardware debouncing on the isolated inputs)

the fallback area of the EEPROM:

mesaflash --device 7i96 --addr xx.xx.xx.xx --write test.bit --fallback

and then load the FPGA from the fallback area of the EEPROM:

mesaflash --device 7i96 --addr xx.xx.xx.xx --reload --fallback

If this fails, you can just power cycle the card and reload the user configuration

As far as MPGs go, running a software encoder on the isolated inputs is one way

but will only work with 5V MPG signals if you have the input common at ground

If you are running LinuxCNC 2.9 you can also get hardware MPG encoders on the isolated

inputs using the inm firmware (the inm firmware also has hardware debouncing on the isolated inputs)

The following user(s) said Thank You: RotarySMP, tommylight

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

07 Aug 2020 14:37 #177622

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Thanks Tommy and Peter. So take it you can not reformat any of the TB1 outputs to encoder inputs.

I don't think I will bother adding linear encoders to this machine (that might be polishing a turd), but for a future build (a better lathe), would probably add them to the expansion pinhead. Can you also run differential signals to the pinhead, or only single ended?

I have been really happy with the Mesa hardware since I got the 5i25+7i77 PnP kit for the Maho, but once you see how flexibly these are, if you put a little effort into learning the full capabilties, it is really impressive hardware you company has produced Peter. Thanks for the ongoing support.

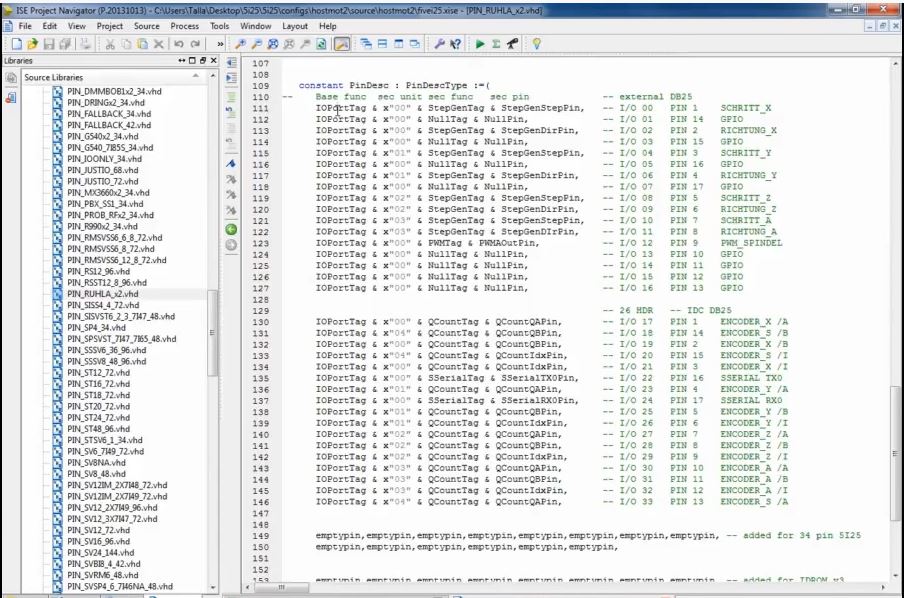

Looking at the configs changes Peter (Talla83) did...

... is there a manual or list of rules of what you can place where, and what doesnt work? He demonstrated on a 7i92, but the 7i96 has more hardware function dedicated pins.

Mark

I don't think I will bother adding linear encoders to this machine (that might be polishing a turd), but for a future build (a better lathe), would probably add them to the expansion pinhead. Can you also run differential signals to the pinhead, or only single ended?

I have been really happy with the Mesa hardware since I got the 5i25+7i77 PnP kit for the Maho, but once you see how flexibly these are, if you put a little effort into learning the full capabilties, it is really impressive hardware you company has produced Peter. Thanks for the ongoing support.

Looking at the configs changes Peter (Talla83) did...

... is there a manual or list of rules of what you can place where, and what doesnt work? He demonstrated on a 7i92, but the 7i96 has more hardware function dedicated pins.

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17626

- Thank you received: 5157

07 Aug 2020 15:01 - 07 Aug 2020 15:02 #177625

by PCW

Replied by PCW on topic Pimping the mini-lathe

On a 7I96 the parallel expansion connector (P1) can have any available function on any pin

but the on board I/O like stepgen pins and isolated inputs have a fixed direction so can only

be used in their designed directions and may have other limitations like maximum speed.

For example the 7I96 stepgen outputs are driven by 5V buffer chips to get a full

5V signal that can drive 24 mA. This buffer only works as an output. Similarly

the isolated input pins can only function as inputs, and are speed limited by

the Optocouplers used for isolation to about 5KHz maximum input frequency.

but the on board I/O like stepgen pins and isolated inputs have a fixed direction so can only

be used in their designed directions and may have other limitations like maximum speed.

For example the 7I96 stepgen outputs are driven by 5V buffer chips to get a full

5V signal that can drive 24 mA. This buffer only works as an output. Similarly

the isolated input pins can only function as inputs, and are speed limited by

the Optocouplers used for isolation to about 5KHz maximum input frequency.

Last edit: 07 Aug 2020 15:02 by PCW.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

07 Aug 2020 16:05 #177628

by Clive S

This is what I have used on a mill using a 7i96 for jogging 3 axis

If you want the hal file as well just shout

Replied by Clive S on topic Pimping the mini-lathe

Given that my lathe only uses a fraction of the 7i96's capacity (2 Stepgen, 1 ENC and 1 Pwmgen) at present, would it be possible to add a further encoder through mesaflash to read a jog wheel? I looked through the bit files, and see there is one that looks like it converts to six ENC (7i96_6enc_d.bit). What would I need to do to make a 1pwmgen+ 1 addition ENC bitfile?

Actually given that jogwheels are only 100 PPR, and the normal input pins are read at 1kHz, I can't hand jog at 10 RPS anyway, so there is probably no disadvantage of puttnig the jog wheel onto general I/O except that they need a few pins.

Bonus question, would it be possible to reconfigure both the two unused Stepgens to ENC? With two stepgens, 1 pwmgen, and 3 Enc (the existing one plus two more), I could add linear encoders to the two axis, and run the jog wheel off I/O. That would be awsome for a lathe.

Mark

This is what I have used on a mill using a 7i96 for jogging 3 axis

# change number of encoders here

loadrt encoder num_chan=5

addf encoder.capture-position servo-thread

addf encoder.update-counters servo-thread

# MPG stuff here

#### load ilowpass for mpg smoothing ###

loadrt ilowpass names=ilowpass.mpgX,ilowpass.mpgY,ilowpass.mpgZ

addf ilowpass.mpgX servo-thread

addf ilowpass.mpgY servo-thread

addf ilowpass.mpgZ servo-thread

setp ilowpass.mpgX.scale 50

setp ilowpass.mpgX.gain 0.01

setp ilowpass.mpgY.scale 50

setp ilowpass.mpgY.gain 0.01

setp ilowpass.mpgZ.scale 50

setp ilowpass.mpgZ.gain .01

# for velocity mode (when you stop spinning the dial the axis stops)

# must be set for each axis

setp joint.0.jog-vel-mode 1

setp axis.x.jog-vel-mode 1

setp joint.1.jog-vel-mode 1

setp axis.y.jog-vel-mode 1

setp joint.2.jog-vel-mode 1

setp axis.z.jog-vel-mode 1

# "times 4 mode" one count per full quadrature cycle, instead of the usual one count per edge.

# mpg jog wheels often have a full quadrature cycle per "click". 0 for off and 1 for on.

setp encoder.0.x4-mode 0

setp encoder.1.x4-mode 0

setp encoder.2.x4-mode 0

#set axis to the required increment ( 0.01)

net jog-inc-x joint.0.jog-scale axis.x.jog-scale

sets jog-inc-x 0.0002

net jog-inc-y joint.1.jog-scale axis.y.jog-scale

sets jog-inc-y 0.0002

net jog-inc-z joint.2.jog-scale axis.z.jog-scale

sets jog-inc-z 0.0002

#set inputs to 7i96

#encoder X

net mpg-xa encoder.0.phase-A <= hm2_7i96.0.gpio.000.in

net mpg-xb encoder.0.phase-B <= hm2_7i96.0.gpio.001.in

#encoder Y

net mpg-ya encoder.1.phase-A <= hm2_7i96.0.gpio.002.in

net mpg-yb encoder.1.phase-B <= hm2_7i96.0.gpio.003.in

#encoder Z

net mpg-za encoder.2.phase-A <= hm2_7i96.0.gpio.004.in

net mpg-zb encoder.2.phase-B <= hm2_7i96.0.gpio.005.in

# send mpg-encoder counts to required axis

# x encoder

net enc-counts-x encoder.0.counts

net enc-counts-x ilowpass.mpgX.in

net enc_out-x ilowpass.mpgX.out

net enc_out-x axis.x.jog-counts

net enc_out-x joint.0.jog-counts

setp axis.x.jog-enable true

setp joint.0.jog-enable true

# Y encoder

net enc-counts-y encoder.1.counts

net enc-counts-y ilowpass.mpgY.in

net enc_out-y ilowpass.mpgY.out

net enc_out-y axis.y.jog-counts

net enc_out-y joint.1.jog-counts

setp axis.y.jog-enable true

setp joint.1.jog-enable true

# Z encoder

net enc-counts-z encoder.2.counts

net enc-counts-z ilowpass.mpgZ.in

net enc_out-z ilowpass.mpgZ.out

net enc_out-z axis.z.jog-counts

net enc_out-z joint.2.jog-counts

setp axis.z.jog-enable true

setp joint.2.jog-enable trueIf you want the hal file as well just shout

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

07 Aug 2020 17:21 - 07 Aug 2020 19:17 #177632

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Thanks Clive, I just ordered a jog encoder. I'll be sure to use this section of your HAL.

Last edit: 07 Aug 2020 19:17 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

09 Aug 2020 11:17 #177741

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Here is episode 26.

Motion at last!

By the way, does anyone have an aswer to a question I posted a couple of days go?

Just playing around, what is the syntax to use natural constants like Pi or "e" in gcode?

Mark

Motion at last!

By the way, does anyone have an aswer to a question I posted a couple of days go?

Just playing around, what is the syntax to use natural constants like Pi or "e" in gcode?

#<103>=[pi/e]

The following user(s) said Thank You: tommylight, Clive S

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

09 Aug 2020 21:21 #177777

by rodw

Replied by rodw on topic Pimping the mini-lathe

The RS274ngc document

tsapps.nist.gov/publication/get_pdf.cfm?pub_id=823374

indicates e exists as EXP but does not explain the usage

I think it will be EXP(n) or EXP[n]

as for pi, I think you would need to define it as a variable.

tsapps.nist.gov/publication/get_pdf.cfm?pub_id=823374

indicates e exists as EXP but does not explain the usage

I think it will be EXP(n) or EXP[n]

as for pi, I think you would need to define it as a variable.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

11 Aug 2020 19:30 #177930

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

I have two problems with the following connections

net spindle-enable <= spindle.0.on

net spindle-enable => hm2_7i96.0.ssr.00.out-00

net spindle-cw <= spindle.0.forward

net spindle-cw => hm2_7i96.0.ssr.00.out-01

net spindle-ccw <= spindle.0.reverse

net spindle-cww => hm2_7i96.0.ssr.00.out-02

When I push Gmoccapy spindle fwd button, both out-00 and out-01 go true. Spindle starts correctly.

When I push the rev rotation button, spindle enable out-00 goes high, but out-02 stay false. I can't see the error.

Second issue:

I am a bit lost with the spindle closed loop connection. I have the following generated by PNCConf

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

net ratio_select.out pid.s.maxoutput

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-pid-out pid.s.output => scale.gear.in

net gear-ratio ratio_select.out-f => scale.gear.gain

setp ratio_select.in00 0.000405

setp ratio_select.in01 0.000175

net gear-select-a => ratio_select.sel0

net spindle-output <= scale.gear.out

# ---Encoder feedback signals/setup---

setp [HMOT](CARD0).encoder.00.counter-mode 0

setp [HMOT](CARD0).encoder.00.filter 1

setp [HMOT](CARD0).encoder.00.index-invert 0

setp [HMOT](CARD0).encoder.00.index-mask 0

setp [HMOT](CARD0).encoder.00.index-mask-invert 0

setp [HMOT](CARD0).encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= [HMOT](CARD0).encoder.00.position

net spindle-vel-fb-rps <= [HMOT](CARD0).encoder.00.velocity

net spindle-index-enable <=> [HMOT](CARD0).encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

I added

net spindle-vel-cmd-rpm-abs => hm2_7i96.0.pwmgen.00.value

but it does respond to a change in command S word.

Thanks for assistance.

Mark

net spindle-enable <= spindle.0.on

net spindle-enable => hm2_7i96.0.ssr.00.out-00

net spindle-cw <= spindle.0.forward

net spindle-cw => hm2_7i96.0.ssr.00.out-01

net spindle-ccw <= spindle.0.reverse

net spindle-cww => hm2_7i96.0.ssr.00.out-02

When I push Gmoccapy spindle fwd button, both out-00 and out-01 go true. Spindle starts correctly.

When I push the rev rotation button, spindle enable out-00 goes high, but out-02 stay false. I can't see the error.

Second issue:

I am a bit lost with the spindle closed loop connection. I have the following generated by PNCConf

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

net ratio_select.out pid.s.maxoutput

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-pid-out pid.s.output => scale.gear.in

net gear-ratio ratio_select.out-f => scale.gear.gain

setp ratio_select.in00 0.000405

setp ratio_select.in01 0.000175

net gear-select-a => ratio_select.sel0

net spindle-output <= scale.gear.out

# ---Encoder feedback signals/setup---

setp [HMOT](CARD0).encoder.00.counter-mode 0

setp [HMOT](CARD0).encoder.00.filter 1

setp [HMOT](CARD0).encoder.00.index-invert 0

setp [HMOT](CARD0).encoder.00.index-mask 0

setp [HMOT](CARD0).encoder.00.index-mask-invert 0

setp [HMOT](CARD0).encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= [HMOT](CARD0).encoder.00.position

net spindle-vel-fb-rps <= [HMOT](CARD0).encoder.00.velocity

net spindle-index-enable <=> [HMOT](CARD0).encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

I added

net spindle-vel-cmd-rpm-abs => hm2_7i96.0.pwmgen.00.value

but it does respond to a change in command S word.

Thanks for assistance.

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.396 seconds