Pimping the mini-lathe

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17601

- Thank you received: 5147

26 Jul 2020 20:05 - 26 Jul 2020 20:07 #175959

by PCW

Replied by PCW on topic Pimping the mini-lathe

so one crude option is

cd ~/mesaflash

sudo cp mesaflash /usr/bin/mesaflash

or alternatively

sudo rm /usr/bin/mesaflash

cd ~/mesaflash

sudo cp mesaflash /usr/bin/mesaflash

or alternatively

sudo rm /usr/bin/mesaflash

Last edit: 26 Jul 2020 20:07 by PCW.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7234

26 Jul 2020 20:57 #175971

by tommylight

Replied by tommylight on topic Pimping the mini-lathe

Sorry, was not sure if you did see that.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

30 Jul 2020 08:41 #176483

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

The PNCConf HAL includes..

I am using open loop steppers, so do I just delete this block, or is this needed for some LinuxCNC internal PID?

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output <= [HMOT](CARD0).stepgen.00.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.00.enableI am using open loop steppers, so do I just delete this block, or is this needed for some LinuxCNC internal PID?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11629

- Thank you received: 3916

30 Jul 2020 08:52 #176484

by rodw

Replied by rodw on topic Pimping the mini-lathe

No, leave it in. Here is mine

See forum.linuxcnc.org/47-hal-examples/34072...ranch-gantry-example

Note that I edited pnccconf output to use joint numbers not axes. I don't have any baggage or preconceived ideas about how things should work becasue I've only ever used 2.8 and above. Doing it this way means you can swap joints around to different axes just by changing one line in your ini file...

Warning: Spoiler!

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i76e.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i76e.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i76e.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i76e.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i76e.0.stepgen.00.step_type 0

setp hm2_7i76e.0.stepgen.00.control-type 1

setp hm2_7i76e.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net 0-pos-cmd <= joint.0.motor-pos-cmd

net 0-vel-cmd <= joint.0.vel-cmd

net 0-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

net 0-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

net 0-pos-fb => joint.0.motor-pos-fb

net 0-enable <= joint.0.amp-enable-out

net 0-enable => hm2_7i76e.0.stepgen.00.enable

See forum.linuxcnc.org/47-hal-examples/34072...ranch-gantry-example

Note that I edited pnccconf output to use joint numbers not axes. I don't have any baggage or preconceived ideas about how things should work becasue I've only ever used 2.8 and above. Doing it this way means you can swap joints around to different axes just by changing one line in your ini file...

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

30 Jul 2020 12:18 - 30 Jul 2020 12:27 #176495

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Thanks Rod.

At this point I am still trying to get my head around the spindle set up. The PNCConf set up the spindle basically as a closed loop servo as far as I can see. Which is pretty cool, but I am a still trying to work out what nets I need to make to get it going, as it is a lot more complicated than what I have on the MAHO.

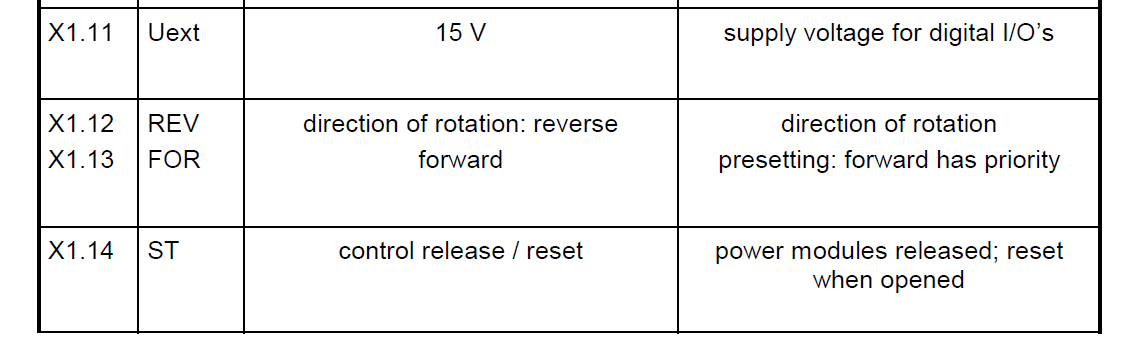

I have the 7i96 PWM output running through the analog conversion card to the VFD working, and have tested speed control with HALshow to

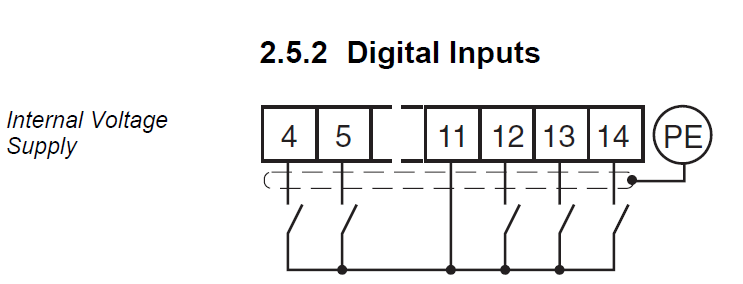

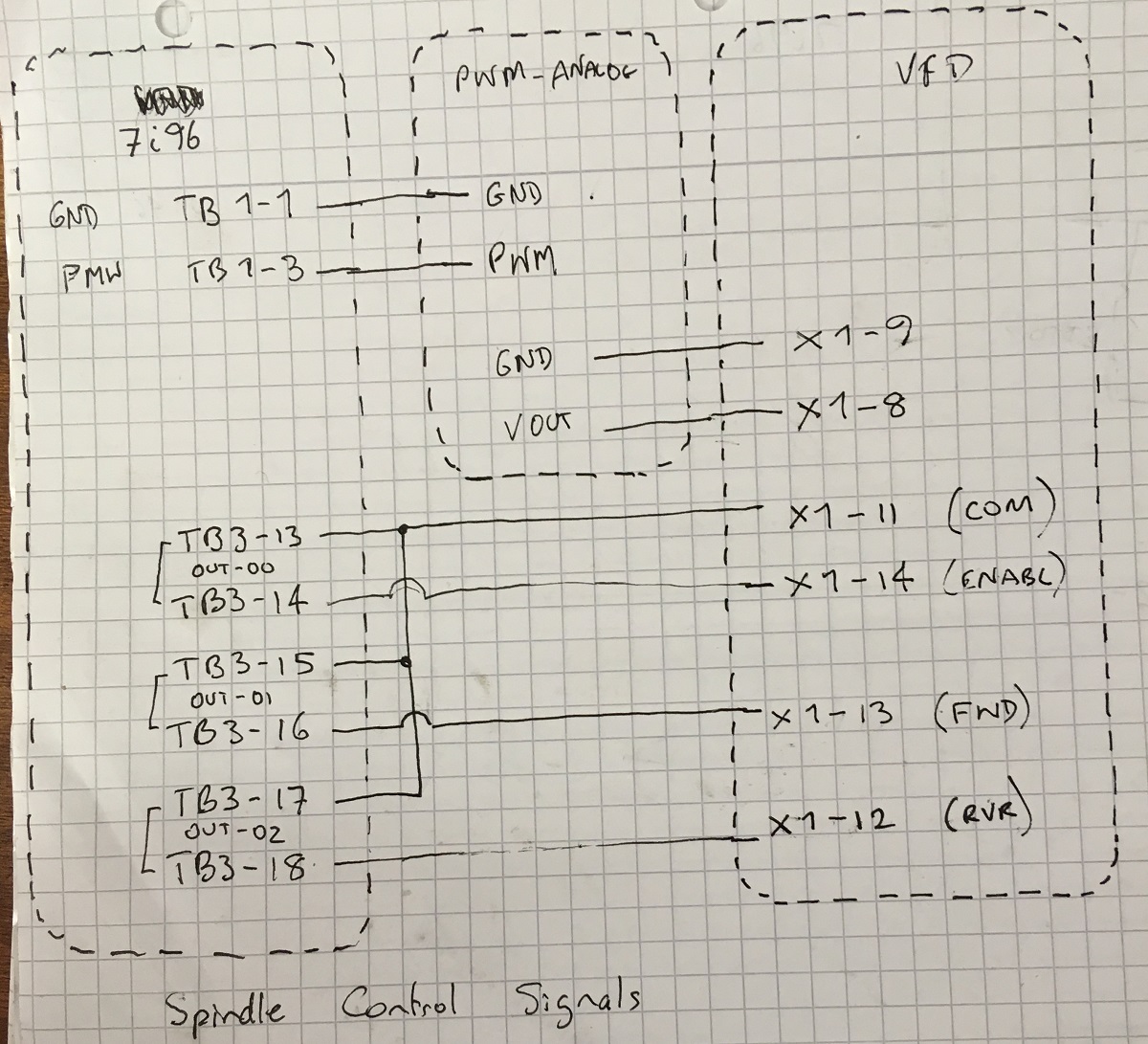

The next issue is the VFD FWD/REV and Enable signal wiring. Three of the 7i96 outputs are hooked up to the VFD .

I can control the 7i96 switches on and off through the HALshow. However, I can't control the VFD, as there is enough leakage current for the VFD to detect them as always on, as the 7i96 output relays are only 15MOhm when off.

<fake know stuff about electronics>

Do I need to add pull down resisters? There is no information in the VFD manual on the max Voltage threshold before it triggers, so I don't know what to plug into the formula provided here

I have a large selection of 1/4W resisters. I tried adding a 1kOhm resister between VFD X1-14 and GND, but it didn't change the state of the VFD Enable. It stays on.

</faking knowledge>

... or do I have a completely different problem?

At this point I am still trying to get my head around the spindle set up. The PNCConf set up the spindle basically as a closed loop servo as far as I can see. Which is pretty cool, but I am a still trying to work out what nets I need to make to get it going, as it is a lot more complicated than what I have on the MAHO.

I have the 7i96 PWM output running through the analog conversion card to the VFD working, and have tested speed control with HALshow to

I am not sure what LinuxCNC spindle speed signal or pin I need to net to that hm2_7i96.0.pwmgen.00.value , or the associated hm2_7i96.0.pwmgen.00.enable? I get a bit lost in the heirarchy of IOcontrol/Motion/HALUI etc pins which all have some spindle connection.setp hm2_7i96.0.pwmgen.00.value xxx

The next issue is the VFD FWD/REV and Enable signal wiring. Three of the 7i96 outputs are hooked up to the VFD .

I can control the 7i96 switches on and off through the HALshow. However, I can't control the VFD, as there is enough leakage current for the VFD to detect them as always on, as the 7i96 output relays are only 15MOhm when off.

<fake know stuff about electronics>

Do I need to add pull down resisters? There is no information in the VFD manual on the max Voltage threshold before it triggers, so I don't know what to plug into the formula provided here

I have a large selection of 1/4W resisters. I tried adding a 1kOhm resister between VFD X1-14 and GND, but it didn't change the state of the VFD Enable. It stays on.

</faking knowledge>

... or do I have a completely different problem?

Attachments:

Last edit: 30 Jul 2020 12:27 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

31 Jul 2020 04:53 - 31 Jul 2020 06:39 #176602

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Just bumping this back up. Does someone have a suggestion of how I can get the 7i96 output signals to switch the VFD reliably please?

Mark

Mark

Last edit: 31 Jul 2020 06:39 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

02 Aug 2020 17:23 #176909

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

I was hoping to have Episode up at the normal time, but the 4K render failed over night, and after changing some settings, it took nearly eight hours to render it, and then three hours to upload it. I'm going back to 1080P.

If anyone has input on how to get the VFD's inputs to play nicely with the 7i96 outputs, I would appreciate it. Also any inputs on how the tie the PWNGen into the LinuxCNC/Gmoccapy pins. Thanks.

Mark

If anyone has input on how to get the VFD's inputs to play nicely with the 7i96 outputs, I would appreciate it. Also any inputs on how the tie the PWNGen into the LinuxCNC/Gmoccapy pins. Thanks.

Mark

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17601

- Thank you received: 5147

02 Aug 2020 18:40 #176921

by PCW

Replied by PCW on topic Pimping the mini-lathe

If the 7I96 outputs seem to be always on, its likely you have the polarity backwards

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

02 Aug 2020 18:54 - 02 Aug 2020 18:56 #176925

by RotarySMP

Replied by RotarySMP on topic Pimping the mini-lathe

Thank PCW. The polarity of the 7i96 switches? I thought these didn't matter. Would you mind taking a quick look at this latest video, at around minute 13:00 I show the behaviour.

Edit.

The 7i96 seems to switch properly, but "off" is a 2MOhm resistance, not an open circuit.

Mark

Edit.

The 7i96 seems to switch properly, but "off" is a 2MOhm resistance, not an open circuit.

Mark

Last edit: 02 Aug 2020 18:56 by RotarySMP.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17601

- Thank you received: 5147

02 Aug 2020 19:04 #176927

by PCW

Replied by PCW on topic Pimping the mini-lathe

I can actually see from your wiring that its backwards

( +15 from VFD pin 11 goes to output- pins but should go to output+ pins )

( +15 from VFD pin 11 goes to output- pins but should go to output+ pins )

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.194 seconds