Schaublin 125-CNC retrofit.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

21 Feb 2021 12:38 - 12 Apr 2024 17:49 #199601

by RotarySMP

Schaublin 125-CNC retrofit. was created by RotarySMP

Hi All,

I bought a Schaublin 125-CNC with pretty good bones which will need the LinuxCNC modernisation.

Mark

I bought a Schaublin 125-CNC with pretty good bones which will need the LinuxCNC modernisation.

Mark

Last edit: 12 Apr 2024 17:49 by RotarySMP.

The following user(s) said Thank You: arvidb, tommylight, besriworld, anfänger, TobiWanCNC

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21297

- Thank you received: 7273

21 Feb 2021 13:34 #199607

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

I feel a build log going on ....

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4653

- Thank you received: 2078

21 Feb 2021 13:56 #199609

by Aciera

Replied by Aciera on topic Schaublin 125-CNC retrofit.

Nice, I was eyeing that one as well but sadly, or luckily for you, I have no more space for yet another machine

I think user trilobyte has done a refit of one of these.

Thanks for the video.

I think user trilobyte has done a refit of one of these.

Thanks for the video.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

21 Feb 2021 15:55 - 12 Apr 2024 17:51 #199631

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Yes, trilobyte's retrofit on the CNCece.de ...

www.cncecke.de/forum/showthread.php?5714...&highlight=schaublin

... was definately a big motivation for me. He measured the base and confirmed it would fit through my door way nearly two years ago. I was tempted by a 125CCN locally, but it was sold to another guy (who has become a friend - Schaublins unite !

!

Glad I hit the buy it now. I have heard from a number of guys who were watching this auction.

Andy Pugh recommended I look at the Mesa 7i29 / 7i49 to run the existing motors and resolvers. The 7i29 doesn have a manual listed on the Mesa web site.

I really like how Trilobyte shoe horned everything into the Pneumatics bay in the machine stand, and deleted the huge electrical cabinet. Pretty amazing bit of pneumatic tetris he did.

Mark

www.cncecke.de/forum/showthread.php?5714...&highlight=schaublin

... was definately a big motivation for me. He measured the base and confirmed it would fit through my door way nearly two years ago. I was tempted by a 125CCN locally, but it was sold to another guy (who has become a friend - Schaublins unite

Glad I hit the buy it now. I have heard from a number of guys who were watching this auction.

Andy Pugh recommended I look at the Mesa 7i29 / 7i49 to run the existing motors and resolvers. The 7i29 doesn have a manual listed on the Mesa web site.

I really like how Trilobyte shoe horned everything into the Pneumatics bay in the machine stand, and deleted the huge electrical cabinet. Pretty amazing bit of pneumatic tetris he did.

Mark

Last edit: 12 Apr 2024 17:51 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4653

- Thank you received: 2078

21 Feb 2021 16:02 #199632

by Aciera

Replied by Aciera on topic Schaublin 125-CNC retrofit.

Have you seen this:

www.mesanet.com/pdf/motion/7i29man.pdf

It's definitely nice to do away with the extra cabinet and it is usually quite amazing what can be built into those machine stands using modern power electronics.

www.mesanet.com/pdf/motion/7i29man.pdf

It's definitely nice to do away with the extra cabinet and it is usually quite amazing what can be built into those machine stands using modern power electronics.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

22 Feb 2021 09:07 #199689

by anfänger

Replied by anfänger on topic Schaublin 125-CNC retrofit.

Really looking forward to see this retrofit

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

22 Feb 2021 11:03 #199695

by RotarySMP

Thanks for the link, that was not available in my browser.

I am having some trouble weighing up the pros and cons of my axis drive options.

Option 1

- retain the permanent magnet DC servos and resolvers and use MESA 7i29 and 7i49 to interface them.

Pro

- Not physical change to motors, and their wiring solutions, which are very well protected in well engineered conduits and of high quality.

Con

- It is not clear how many mesa cards I would need. I'd like to have the PC up in the user module, and ethernet to a FPGA Mesa in the electrical cabinet. Plus a 7i73 back up in the user module.

- Need to retain the huge three phase transformer and add a (big?) rectifier to provide DC muscle power to the 7i29

- Lack of knowledge of the control technology (resovers, 7i29, 7i49 etc).

Option 2

- Replace the axis drive motors with 750W AC servos. I'd like to use the 7i96, or 7i76E (need to add up the IO). + 7i73

Pro

- Dump the huge transformer.

- Small compact drivers.

- Step/Dir interface (not sure if that is an advantage or not?)

-but also like to return the AC Servo driver encoder signal to LinuxCNC to close the position loop (or is that overkill, if you have no linear scales).

- Quiet/smooth

- leverage 7i96 knowledge I already gained.

Con

- Need to mechanically mount motors, need new pulley etc

- Not sure if I can get the cables routed down the existing, very well engineered conduits.

I am estimating that the price if probably a wash. The 7i29 and 7i49 are pretty expensive, and there would be other cards as well. It might come out little less than two AC servos plus shipping and customs though.

Getting everything into the current pneumatic bay and deleting the huge control cabinet is a major design goal, so the more compact solution will probably win out over the most inexpensive.

Mark

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Have you seen this:

www.mesanet.com/pdf/motion/7i29man.pdf

It's definitely nice to do away with the extra cabinet and it is usually quite amazing what can be built into those machine stands using modern power electronics.

Thanks for the link, that was not available in my browser.

I am having some trouble weighing up the pros and cons of my axis drive options.

Option 1

- retain the permanent magnet DC servos and resolvers and use MESA 7i29 and 7i49 to interface them.

Pro

- Not physical change to motors, and their wiring solutions, which are very well protected in well engineered conduits and of high quality.

Con

- It is not clear how many mesa cards I would need. I'd like to have the PC up in the user module, and ethernet to a FPGA Mesa in the electrical cabinet. Plus a 7i73 back up in the user module.

- Need to retain the huge three phase transformer and add a (big?) rectifier to provide DC muscle power to the 7i29

- Lack of knowledge of the control technology (resovers, 7i29, 7i49 etc).

Option 2

- Replace the axis drive motors with 750W AC servos. I'd like to use the 7i96, or 7i76E (need to add up the IO). + 7i73

Pro

- Dump the huge transformer.

- Small compact drivers.

- Step/Dir interface (not sure if that is an advantage or not?)

-but also like to return the AC Servo driver encoder signal to LinuxCNC to close the position loop (or is that overkill, if you have no linear scales).

- Quiet/smooth

- leverage 7i96 knowledge I already gained.

Con

- Need to mechanically mount motors, need new pulley etc

- Not sure if I can get the cables routed down the existing, very well engineered conduits.

I am estimating that the price if probably a wash. The 7i29 and 7i49 are pretty expensive, and there would be other cards as well. It might come out little less than two AC servos plus shipping and customs though.

Getting everything into the current pneumatic bay and deleting the huge control cabinet is a major design goal, so the more compact solution will probably win out over the most inexpensive.

Mark

Please Log in or Create an account to join the conversation.

- anfänger

-

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

22 Feb 2021 11:59 - 22 Feb 2021 13:58 #199696

by anfänger

Replied by anfänger on topic Schaublin 125-CNC retrofit.

Ive done both, with my Chiron I kept the old servo‘s and drives.

With the Gildemeister I scrapped everything and made all new parts, but I kept the big Control cabinet, cause I didn‘t have a smaller one.

I don’t know If I would go for step Dir with servo‘s. But mainly cause I have no experience with step dir.

The gamble is: will some of the old parts fail in the near future...

With the Gildemeister I scrapped everything and made all new parts, but I kept the big Control cabinet, cause I didn‘t have a smaller one.

I don’t know If I would go for step Dir with servo‘s. But mainly cause I have no experience with step dir.

The gamble is: will some of the old parts fail in the near future...

Last edit: 22 Feb 2021 13:58 by anfänger.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

22 Feb 2021 12:23 - 22 Feb 2021 12:24 #199698

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

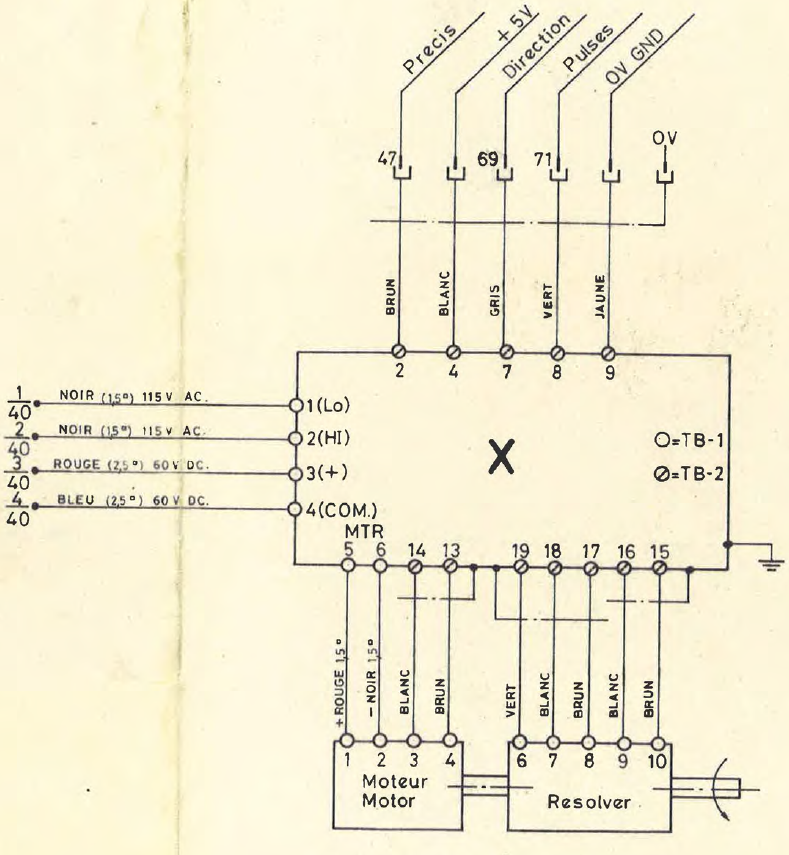

Attachments:

Last edit: 22 Feb 2021 12:24 by RotarySMP.

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

22 Feb 2021 12:57 #199700

by db1981

Replied by db1981 on topic Schaublin 125-CNC retrofit.

Hi Mark,

Do you know what kind of Servos that are? brushed or brushless? Seems like brushed motors (+ - , 3 and 4 are thin thermo sensor wires?).

Are this realy resolvers? (may be wrong word in the schematics?) Usally at this time with brushed motors there are Tachos oder Encoders mounted. There is no need for the DC Amp to know the rotor position. And for an normal resolver there are min. 6 wires needed.

looks like an encoder (+,-,A,B,Zero).

Do you know what kind of Servos that are? brushed or brushless? Seems like brushed motors (+ - , 3 and 4 are thin thermo sensor wires?).

Are this realy resolvers? (may be wrong word in the schematics?) Usally at this time with brushed motors there are Tachos oder Encoders mounted. There is no need for the DC Amp to know the rotor position. And for an normal resolver there are min. 6 wires needed.

looks like an encoder (+,-,A,B,Zero).

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.167 seconds