Brother TC-225 / TC-229 adventure!

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21053

- Thank you received: 7181

22 Jun 2020 21:35 #172398

by tommylight

Replied by tommylight on topic Brother TC-225 / TC-229 adventure!

There is the possibility of using the Mesa 7i76 with a servo spindle as follows:

-Use an external power supply to provide 10V to the spindle control on the 7i76

-Use the spindle output and ground wired to the servo drive input

-That will work properly for the full range of the spindle but only one direction

-so changing the direction is not an easy option

That is all assuming you have a +-10V controlled servo drive/spindle.

-Use an external power supply to provide 10V to the spindle control on the 7i76

-Use the spindle output and ground wired to the servo drive input

-That will work properly for the full range of the spindle but only one direction

-so changing the direction is not an easy option

That is all assuming you have a +-10V controlled servo drive/spindle.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

22 Jun 2020 21:54 #172399

by ihavenofish

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Hmm, looking through the boards. I guess I could just use both my 7i76 and 7i77 at the same time.

Then I could potentially use the axis servo encoders too. Is this a valid plan, or do these not play well together?

Then I could potentially use the axis servo encoders too. Is this a valid plan, or do these not play well together?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

22 Jun 2020 21:56 #172400

by ihavenofish

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

I read about that in the manual, I want true servo control here, like an axis though.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21053

- Thank you received: 7181

22 Jun 2020 22:30 #172402

by tommylight

Replied by tommylight on topic Brother TC-225 / TC-229 adventure!

Oh you have both !

Nice, then yes you can use both for well everything you need, including encoder feedback or glass scales.

They do play very well together.

Nice, then yes you can use both for well everything you need, including encoder feedback or glass scales.

They do play very well together.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

23 Jun 2020 00:11 #172407

by ihavenofish

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

ah, good. ill do that then.

I need a "panel" for it, until I can make something up that's more fancy. I have a 10" display port screen. probably just laser cut and bend a sheet of stainless with holes for the various knobs, buttons, mpg, the screen, a flat industrial keyboard. I used to use a mac pro keyboard (we had boxes of them at the studio because everyone hated them!). Poor thing lasted a week, chips got under all the keys, and then it just bent in half. ha.

I need a "panel" for it, until I can make something up that's more fancy. I have a 10" display port screen. probably just laser cut and bend a sheet of stainless with holes for the various knobs, buttons, mpg, the screen, a flat industrial keyboard. I used to use a mac pro keyboard (we had boxes of them at the studio because everyone hated them!). Poor thing lasted a week, chips got under all the keys, and then it just bent in half. ha.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

23 Jun 2020 03:45 #172415

by ihavenofish

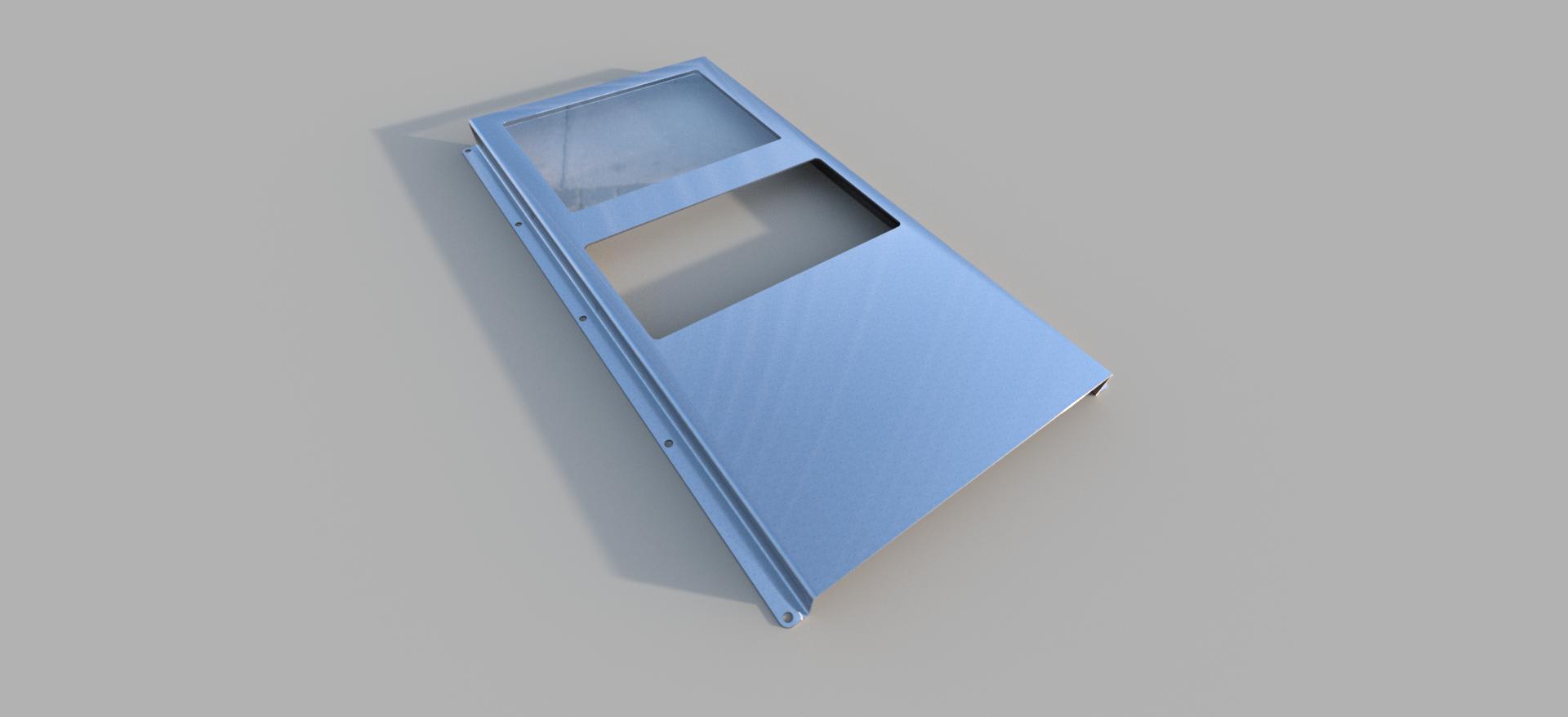

little laser cut and bent stainless panel

petg monitor cover "glass" will be machined on the mill itself.

monitor is the apple retina display with displayport card ($179 at adafruit)

second cutout is for this waterproof keyboard ($79)

below that we will arrange switches, buttons, leds, mpg wheel.

the inside will be 3d printed abs to hold everything in place.

We'll see what the laser cutting runs. My supplier is $125cdn min and usually you get a fair bit for that, so I should get 2, maybe 3 or 4 panels. I only need 2, so if they do end up giving me more than 2, ill offer them up to anyone here if they want.

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

little laser cut and bent stainless panel

petg monitor cover "glass" will be machined on the mill itself.

monitor is the apple retina display with displayport card ($179 at adafruit)

second cutout is for this waterproof keyboard ($79)

below that we will arrange switches, buttons, leds, mpg wheel.

the inside will be 3d printed abs to hold everything in place.

We'll see what the laser cutting runs. My supplier is $125cdn min and usually you get a fair bit for that, so I should get 2, maybe 3 or 4 panels. I only need 2, so if they do end up giving me more than 2, ill offer them up to anyone here if they want.

Please Log in or Create an account to join the conversation.

- IceBear

-

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

23 Jun 2020 08:44 - 23 Jun 2020 09:50 #172450

by IceBear

Replied by IceBear on topic Brother TC-225 / TC-229 adventure!

Hi Ihavenofish!

actually I have Brother TC-215 with original Toshiba servo drives...and I manage to retrofit it ONLY with pin-to-pin replacement NC-Board with Mesa 7i92 and 7i77. It's work incredibly precice (I think due internal resolver) (precise is about 0.002mm)

first chips

So if your drives and motors initially work fine, I hope You can do the same and save cost and time.

and save cost and time.

Ready to share all info with all comunity.

actually I have Brother TC-215 with original Toshiba servo drives...and I manage to retrofit it ONLY with pin-to-pin replacement NC-Board with Mesa 7i92 and 7i77. It's work incredibly precice (I think due internal resolver) (precise is about 0.002mm)

first chips

So if your drives and motors initially work fine, I hope You can do the same

Ready to share all info with all comunity.

Last edit: 23 Jun 2020 09:50 by IceBear.

Please Log in or Create an account to join the conversation.

- IceBear

-

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

23 Jun 2020 09:30 - 23 Jun 2020 09:55 #172455

by IceBear

Replied by IceBear on topic Brother TC-225 / TC-229 adventure!

About toolchange..... it takes most of my efforts.

Would like to say many thanks for laserK3000/tc215Retrofit github link

There are 2 main important part.

1. Spindle orientation with m19... rotate spindle and bt30 to mach the ATC fixture.

this done with .hal orient and finaly work perfect!

2. M6 gcode substitute script....is:

1. check index enable

2. check z location ( if z>0 not safe to rotate spindle!)

3. extend z softlimits (+150 - -200)

4. orient spindle with m19

5. move spindle to Z (+150) (ATC Home switch)

6. check atc home switch is on (safe place to rotate atc toolcrib)

7. determine nearest path and direction to rotate toolcrib.

8. read ATC encoder and control ATC motor (to drive to destination pochet)

9. move Z to 0

10. limit back softlimits to (0 - -200)

Script with a lot of debug messages attached.

video about toolchange script testing

video abou softlimits change

Would like to say many thanks for laserK3000/tc215Retrofit github link

There are 2 main important part.

1. Spindle orientation with m19... rotate spindle and bt30 to mach the ATC fixture.

this done with .hal orient and finaly work perfect!

2. M6 gcode substitute script....is:

1. check index enable

2. check z location ( if z>0 not safe to rotate spindle!)

3. extend z softlimits (+150 - -200)

4. orient spindle with m19

5. move spindle to Z (+150) (ATC Home switch)

6. check atc home switch is on (safe place to rotate atc toolcrib)

7. determine nearest path and direction to rotate toolcrib.

8. read ATC encoder and control ATC motor (to drive to destination pochet)

9. move Z to 0

10. limit back softlimits to (0 - -200)

Script with a lot of debug messages attached.

video about toolchange script testing

video abou softlimits change

Last edit: 23 Jun 2020 09:55 by IceBear.

The following user(s) said Thank You: akb1212

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

23 Jun 2020 10:22 #172457

by ihavenofish

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Thanks

If you go earlier in this thread, youll find that the original sanyo motors could not be tuned. perhaps the Toshibas behave much better.

On my TC229, the drives are proprietary serial, (and mine were dead anyway), so there was no using those.

If you go earlier in this thread, youll find that the original sanyo motors could not be tuned. perhaps the Toshibas behave much better.

On my TC229, the drives are proprietary serial, (and mine were dead anyway), so there was no using those.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 936

- Thank you received: 228

23 Jun 2020 15:01 #172476

by ihavenofish

Replied by ihavenofish on topic Brother TC-225 / TC-229 adventure!

Oh, thanks for the orientation notes. I'll have to check into it. It's not going to allow the all in one motion, but it will work to start by the look of what you did

Please Log in or Create an account to join the conversation.

Time to create page: 0.226 seconds