Mini wannabe datron build

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21231

- Thank you received: 7249

25 Jun 2024 23:23 #303798

by tommylight

Replied by tommylight on topic Mini wannabe datron build

Stuxnet ???

Centrifuges n stuff for enriching that green stuff that shall not be mentioned, as i do not want to end up on a list, if i ever got to US.

Centrifuges n stuff for enriching that green stuff that shall not be mentioned, as i do not want to end up on a list, if i ever got to US.

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 923

- Thank you received: 275

25 Jun 2024 23:43 #303800

by cakeslob

Replied by cakeslob on topic Mini wannabe datron build

in canada the green stuff is something else. we mine the yellow stuff

holy shit, this export restrictions list is fascinating. restrictions on cnc machines, cmm, LDVT, certain carbide shapes

but yeah fish, im pretty sure we live in the same greater area

holy shit, this export restrictions list is fascinating. restrictions on cnc machines, cmm, LDVT, certain carbide shapes

but yeah fish, im pretty sure we live in the same greater area

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

26 Jun 2024 02:16 - 26 Jun 2024 02:27 #303805

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

ahh ok.

cool.

Want a machine? hahahaha.

I've been rolling all my numbers and am pretty close to setting a price for 2 early bird buyers. Its looking very promising. for the price of a loaded tormach 440 mine has delta servos, "high speed" atc spindle, laser tool setter, probe, thk ground screws and precision grade rails. 1500 inch per min rapids.

I hope I can figure out how to make it appeal to people who are in that zone (as opposed to the ones that want a shapeoko, or on the other end a real datron)

If the long mill guys can sell 200 machines a month, I am pretty sure I can manage 2!

cool.

Want a machine? hahahaha.

I've been rolling all my numbers and am pretty close to setting a price for 2 early bird buyers. Its looking very promising. for the price of a loaded tormach 440 mine has delta servos, "high speed" atc spindle, laser tool setter, probe, thk ground screws and precision grade rails. 1500 inch per min rapids.

I hope I can figure out how to make it appeal to people who are in that zone (as opposed to the ones that want a shapeoko, or on the other end a real datron)

If the long mill guys can sell 200 machines a month, I am pretty sure I can manage 2!

Last edit: 26 Jun 2024 02:27 by ihavenofish.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

26 Jun 2024 07:11 - 26 Jun 2024 07:12 #303812

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

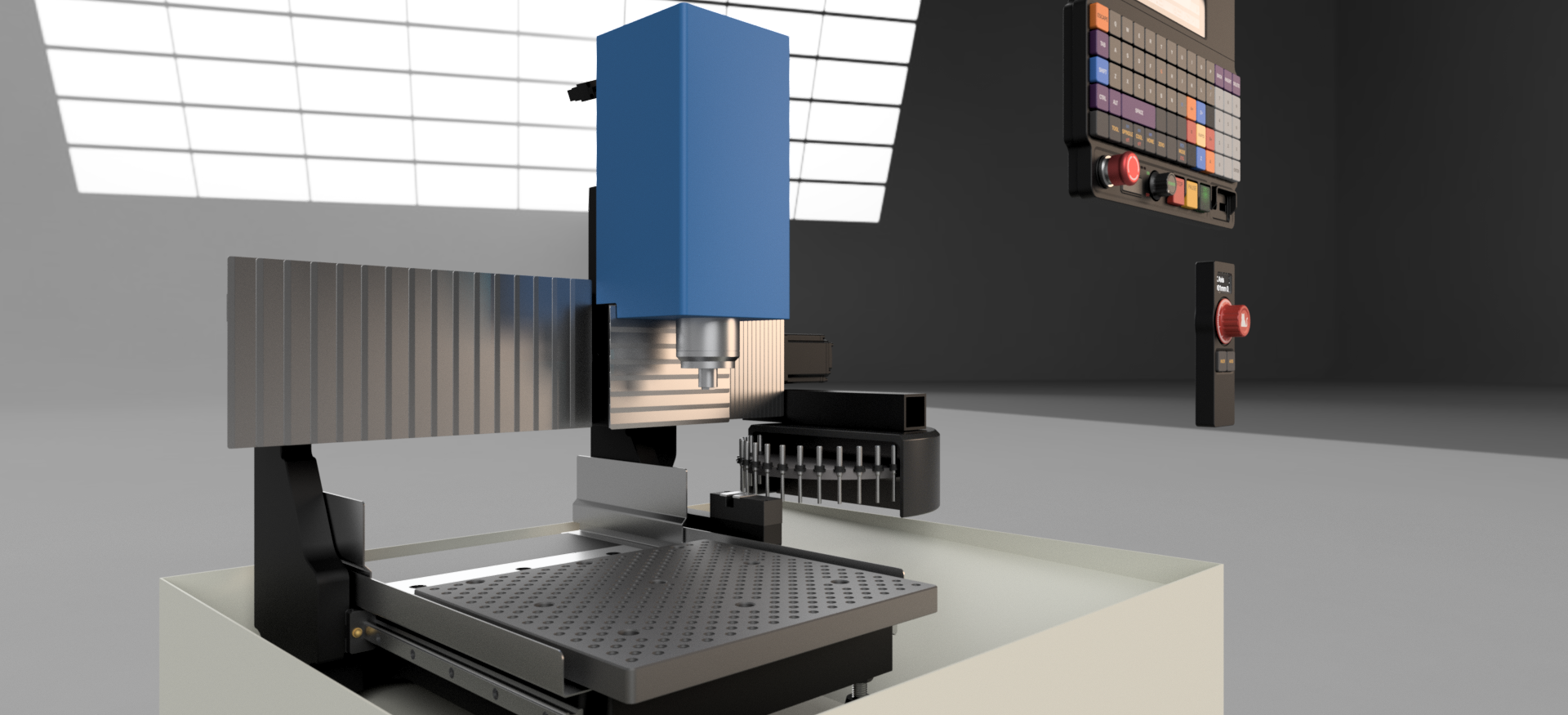

Ride along tool mag. I was having issues finding a sensible way to mount a more simple side tray mag, because having to grab the tool shank means you need very precise positioning. Makes it a lot easier to just have it ride on the Y axis. Holds 15 cutters up to 8mm and 100mm long. it is a half moon mag so it will spin and close itself out of the travel area with no need for any air cylinder. The laser tool setter is inboard of the mag. It needs some sort of retracting cover to keep chips off it. It has an air blast inside to keep the laser line clean. Cover should be opened mechanically by axis travel into the atc zone.

I think the magazine itself will be SLS nylon printed. That should be fun all by itself haha. (the blue spindle/z cover will also be nylon as well as the mounting parts for the way covers.

I think the magazine itself will be SLS nylon printed. That should be fun all by itself haha. (the blue spindle/z cover will also be nylon as well as the mounting parts for the way covers.

Attachments:

Last edit: 26 Jun 2024 07:12 by ihavenofish.

The following user(s) said Thank You: rodw, besriworld

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

27 Jun 2024 00:55 #303861

by ihavenofish

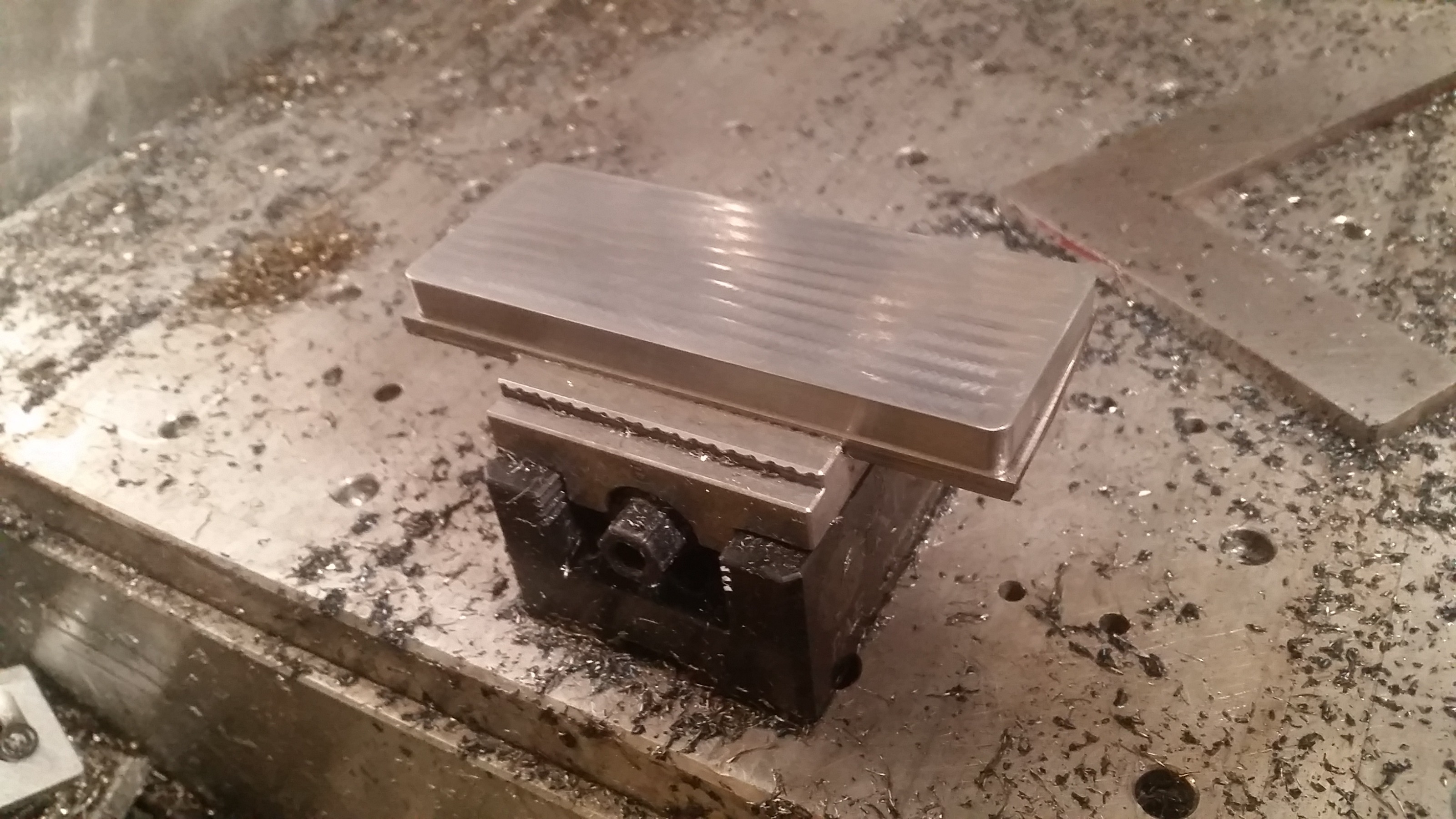

A little testing of depth of cut.

29mm deep, 0.3mm step over, 4119mm/m, 36000rpm.

There is a lot of deflection. Some from the cutter, some from the machine, and some from the spindle. Didn't measure but id say at least 0.002" at the bottom of the cut. Picture is after climb, then back conventional, then climb again at 4119mm/m which fully cleaned it up.

I think this is near the practical limit of depth on the prototype machine. I had to cut the end mill shank down to remove any excess stick out. The stock tool was 35mm or so longer and would chatter and deflect a lot on 1/10 the feed. Doesn't chatter now that its shortened.

Can't wait to try some adaptive clearing with this cutter now.

Replied by ihavenofish on topic Mini wannabe datron build

A little testing of depth of cut.

29mm deep, 0.3mm step over, 4119mm/m, 36000rpm.

There is a lot of deflection. Some from the cutter, some from the machine, and some from the spindle. Didn't measure but id say at least 0.002" at the bottom of the cut. Picture is after climb, then back conventional, then climb again at 4119mm/m which fully cleaned it up.

I think this is near the practical limit of depth on the prototype machine. I had to cut the end mill shank down to remove any excess stick out. The stock tool was 35mm or so longer and would chatter and deflect a lot on 1/10 the feed. Doesn't chatter now that its shortened.

Can't wait to try some adaptive clearing with this cutter now.

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

27 Jun 2024 02:51 - 27 Jun 2024 02:51 #303868

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Attachments:

Last edit: 27 Jun 2024 02:51 by ihavenofish.

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

- Offline

- Senior Member

-

Less

More

- Posts: 66

- Thank you received: 36

27 Jun 2024 06:51 #303873

by Mr. Mass

Replied by Mr. Mass on topic Mini wannabe datron build

About VFD 1000Hz and more, delta series MS300 and MH300 are available up to 1500Hz. If it is possible to buy used Danfoss 2800 and 2900 series also up to 1000Hz. And so there are many chinese manufacturers, there saw up to 6000Hz.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

27 Jun 2024 07:39 - 27 Jun 2024 07:43 #303875

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

All banned.

Customs will seize them if they find them and you can genuinely go to jail. There's no messing around here.

Also, for clarity these are machines I will sell to customers. So no used items for rando chinese inverters, even if it was legal.

Customs will seize them if they find them and you can genuinely go to jail. There's no messing around here.

Also, for clarity these are machines I will sell to customers. So no used items for rando chinese inverters, even if it was legal.

Last edit: 27 Jun 2024 07:43 by ihavenofish.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

27 Jun 2024 08:07 #303877

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

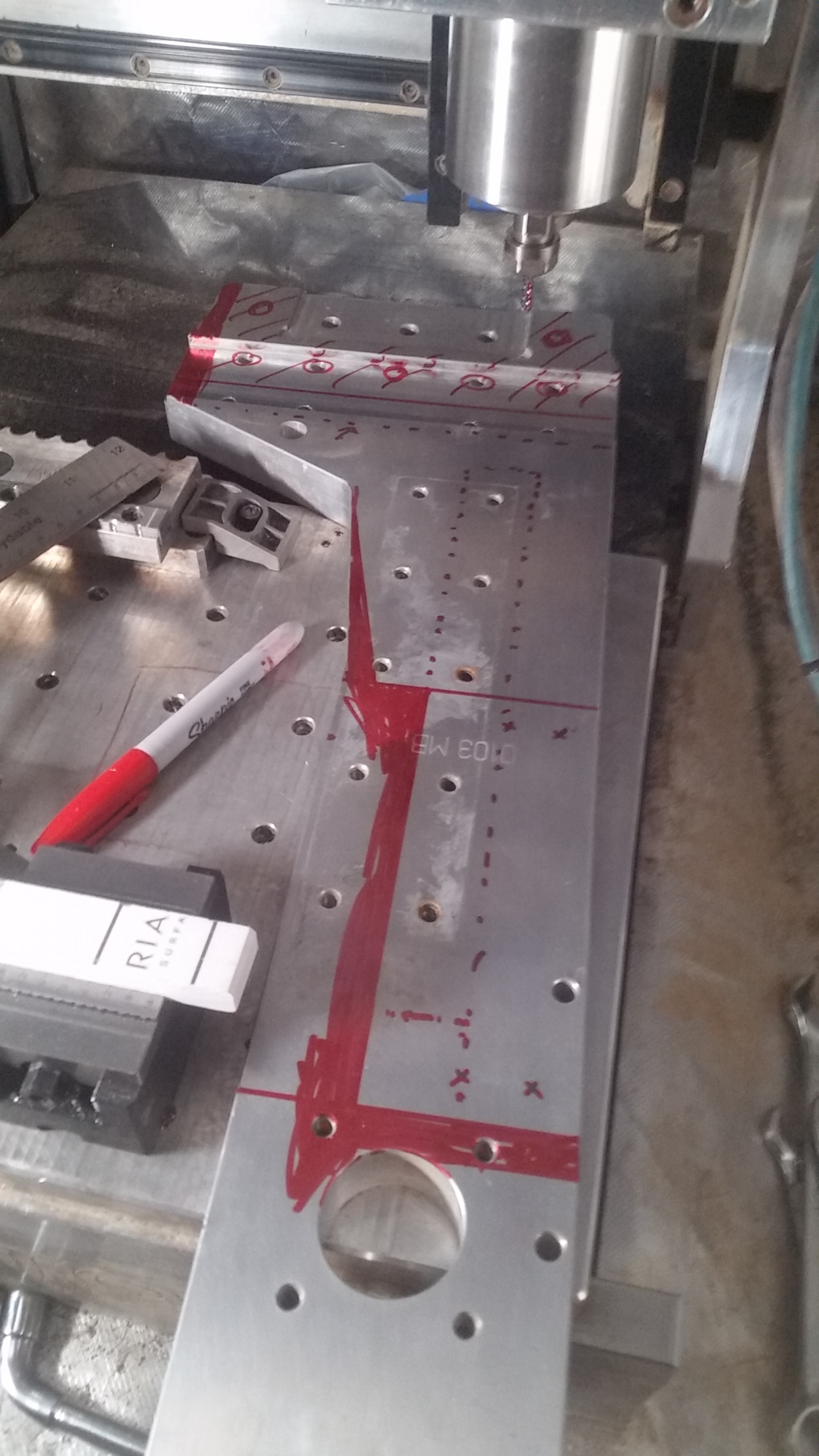

For my next trick: O-1 tool steel (soft).

This is the first proper "sample part" I am going to video to market the new machine. Just waiting on my 4mm end mills to come today or tomorrow I hope.

I expect only one real issue with the fine surfacing on the steel and that is the lack of jerk control and stepper tuning. It will probably leave marks at transitions is my expectation.

This is the first proper "sample part" I am going to video to market the new machine. Just waiting on my 4mm end mills to come today or tomorrow I hope.

I expect only one real issue with the fine surfacing on the steel and that is the lack of jerk control and stepper tuning. It will probably leave marks at transitions is my expectation.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 255

29 Jun 2024 21:12 #304059

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

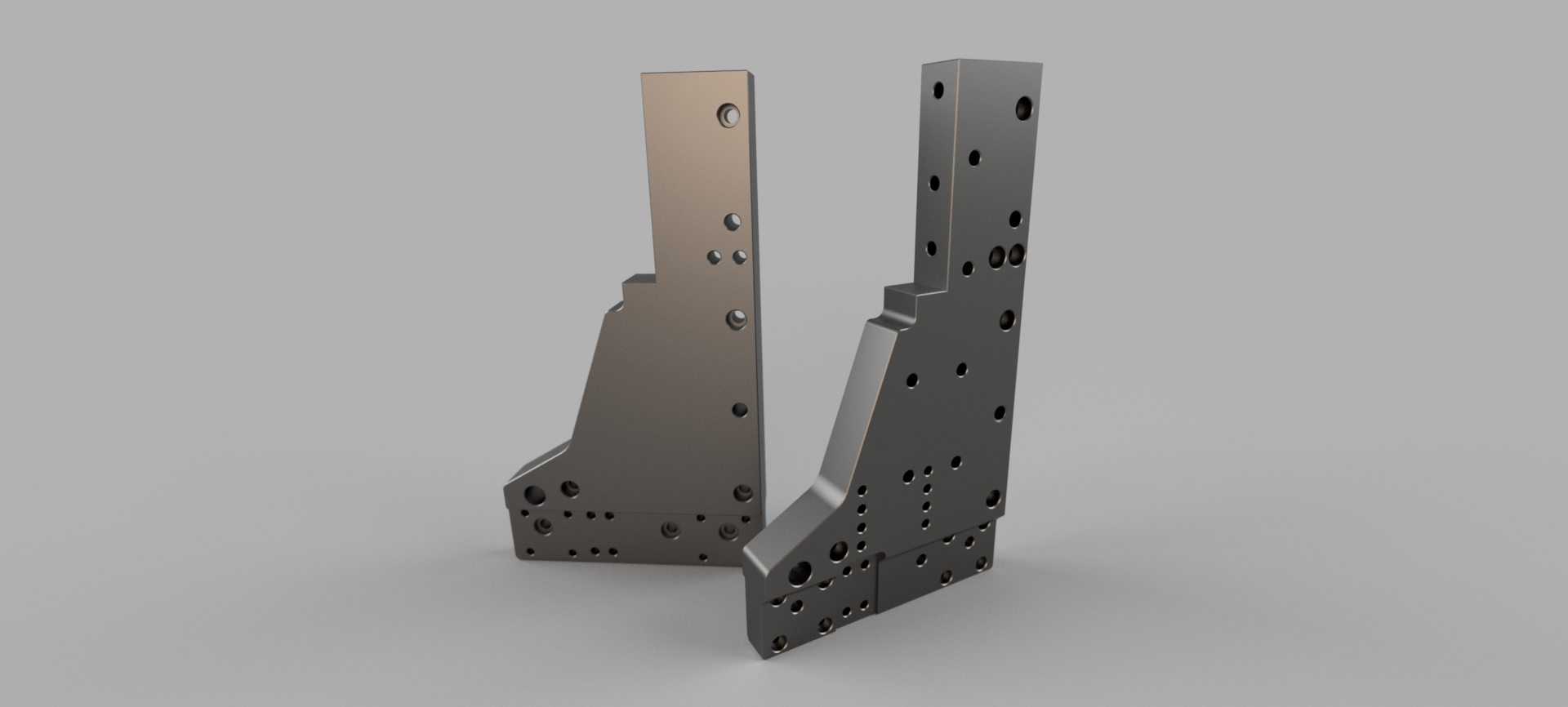

Uprights for V1/V2 minimonster. V1 is single drive aluminium base frame, V2 is dual drive, granite base, these uprights can be used for both. As you can see, for this first one I am re-milling out of the old large predator uprights. Not reusing any features, just working around the holes to use it as stock.

I'd already made a Z axis, but I went and changed a few things on it, so I need to make another.

I'd already made a Z axis, but I went and changed a few things on it, so I need to make another.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.352 seconds