Mini wannabe datron build

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

30 Jun 2024 15:04 #304087

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

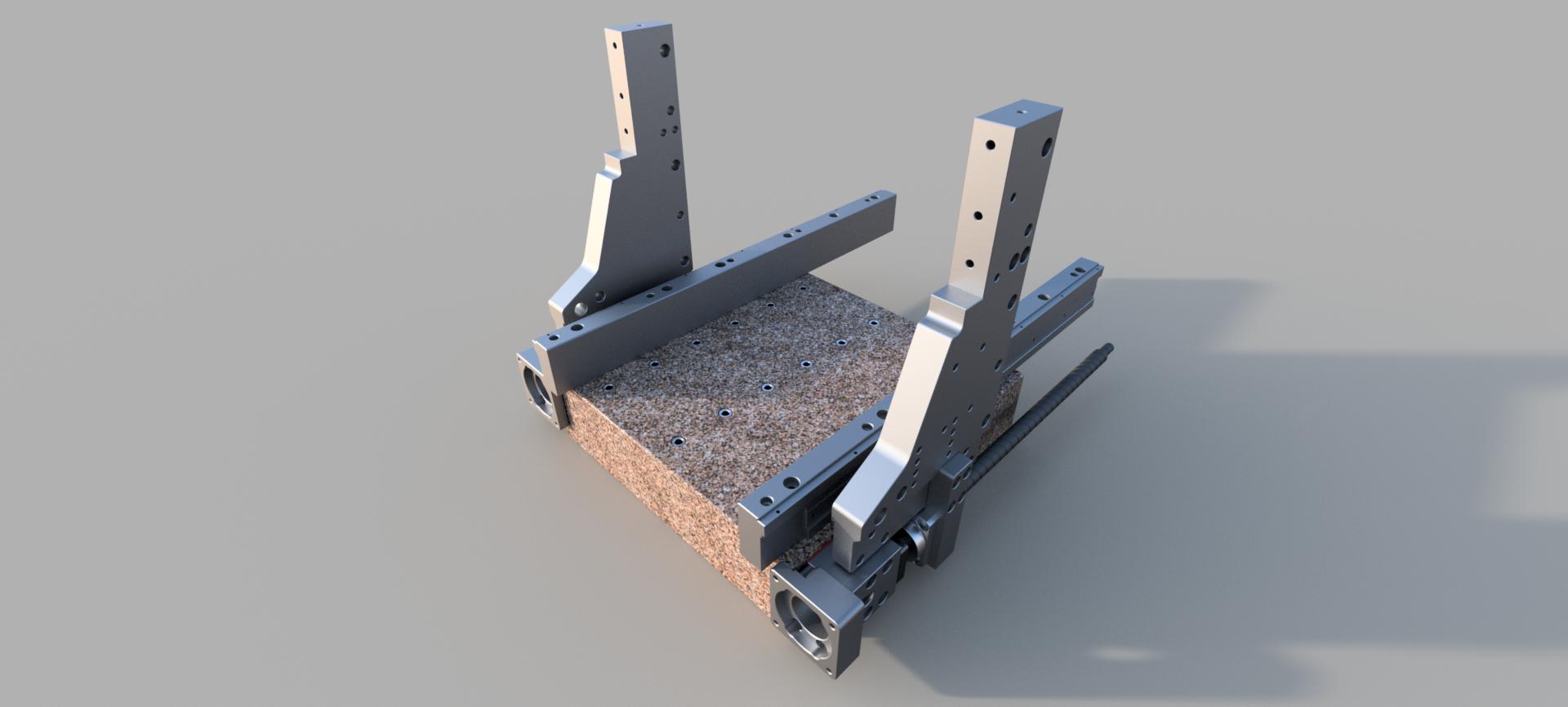

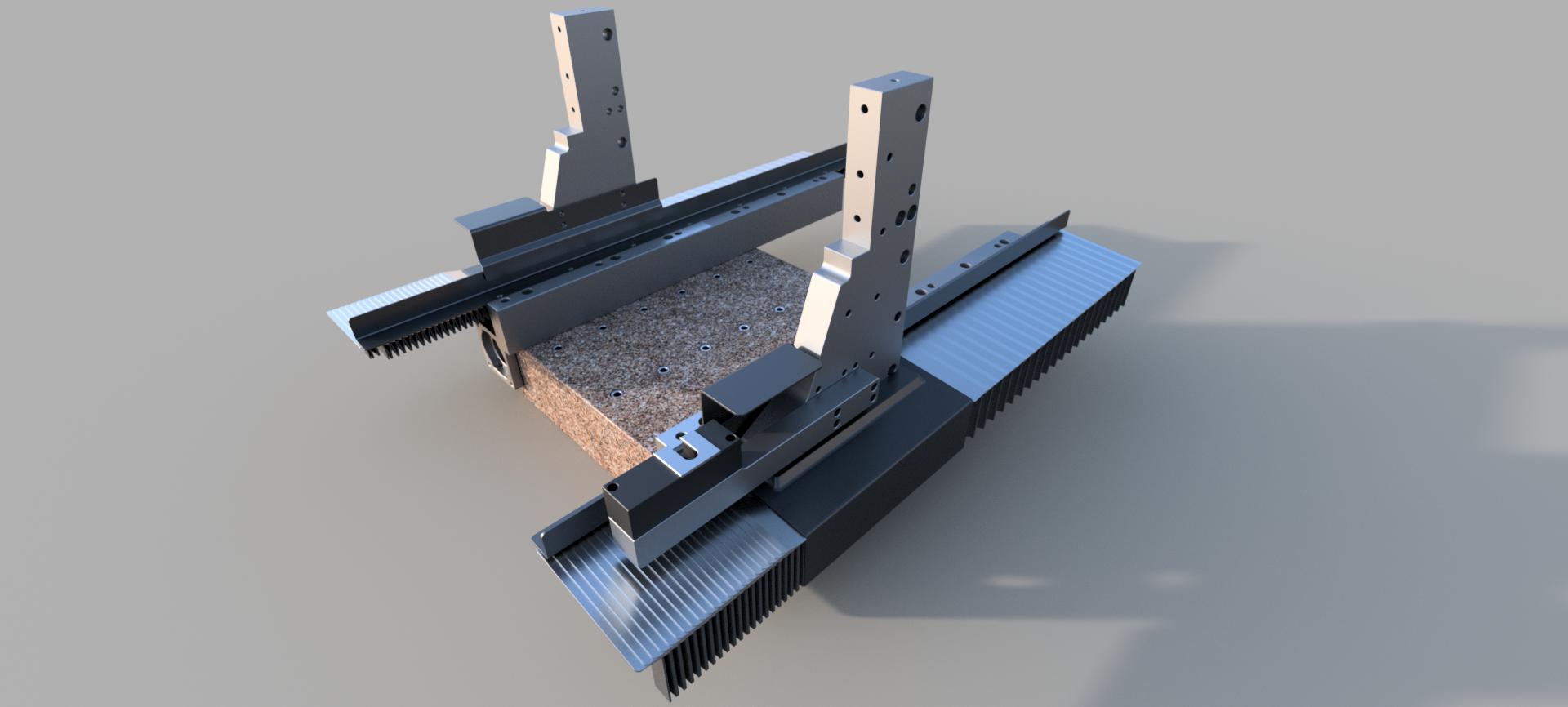

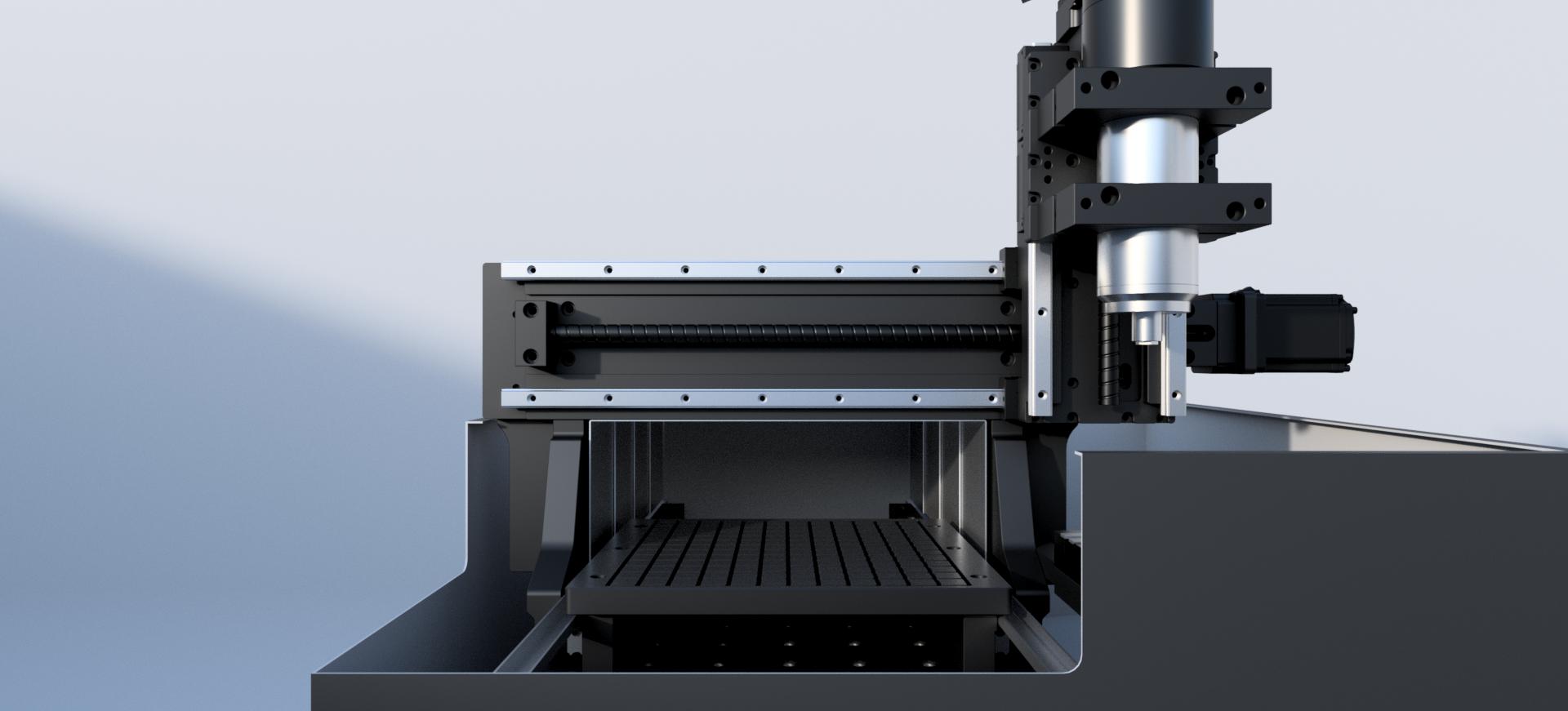

Base parts ready to mill.

This is "v2" with the granite plate. Using a temp 12x12 plate cause its here, but it will move to a larger 12x18 plate later.

Stainless threaded inserts into the granite will be fun. I *think* I have a system down to drill and install them. We'll see haha.

Once this base assembly is done I can stick some ethercat servos on and start working out the control. Absolute servos I want to try so the gantry is always precise and you only need to rehome/rack adjust after a disaster.

I'm wondering about mapping now.

I know we can do screw mapping, so our linear 2d motion can be made very precise. But what about 3d compensation? Compensating for deviations from straightness and squareness? I expect to be mechanically good to 0.0005" over the envelope, but I'm curious if we could map it to be even better. I'm not sure how you'd even measure it to enter in values.

This is "v2" with the granite plate. Using a temp 12x12 plate cause its here, but it will move to a larger 12x18 plate later.

Stainless threaded inserts into the granite will be fun. I *think* I have a system down to drill and install them. We'll see haha.

Once this base assembly is done I can stick some ethercat servos on and start working out the control. Absolute servos I want to try so the gantry is always precise and you only need to rehome/rack adjust after a disaster.

I'm wondering about mapping now.

I know we can do screw mapping, so our linear 2d motion can be made very precise. But what about 3d compensation? Compensating for deviations from straightness and squareness? I expect to be mechanically good to 0.0005" over the envelope, but I'm curious if we could map it to be even better. I'm not sure how you'd even measure it to enter in values.

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

01 Jul 2024 04:55 #304122

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

02 Jul 2024 21:47 #304277

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Attachments:

The following user(s) said Thank You: tommylight, besriworld

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

03 Jul 2024 00:18 #304286

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

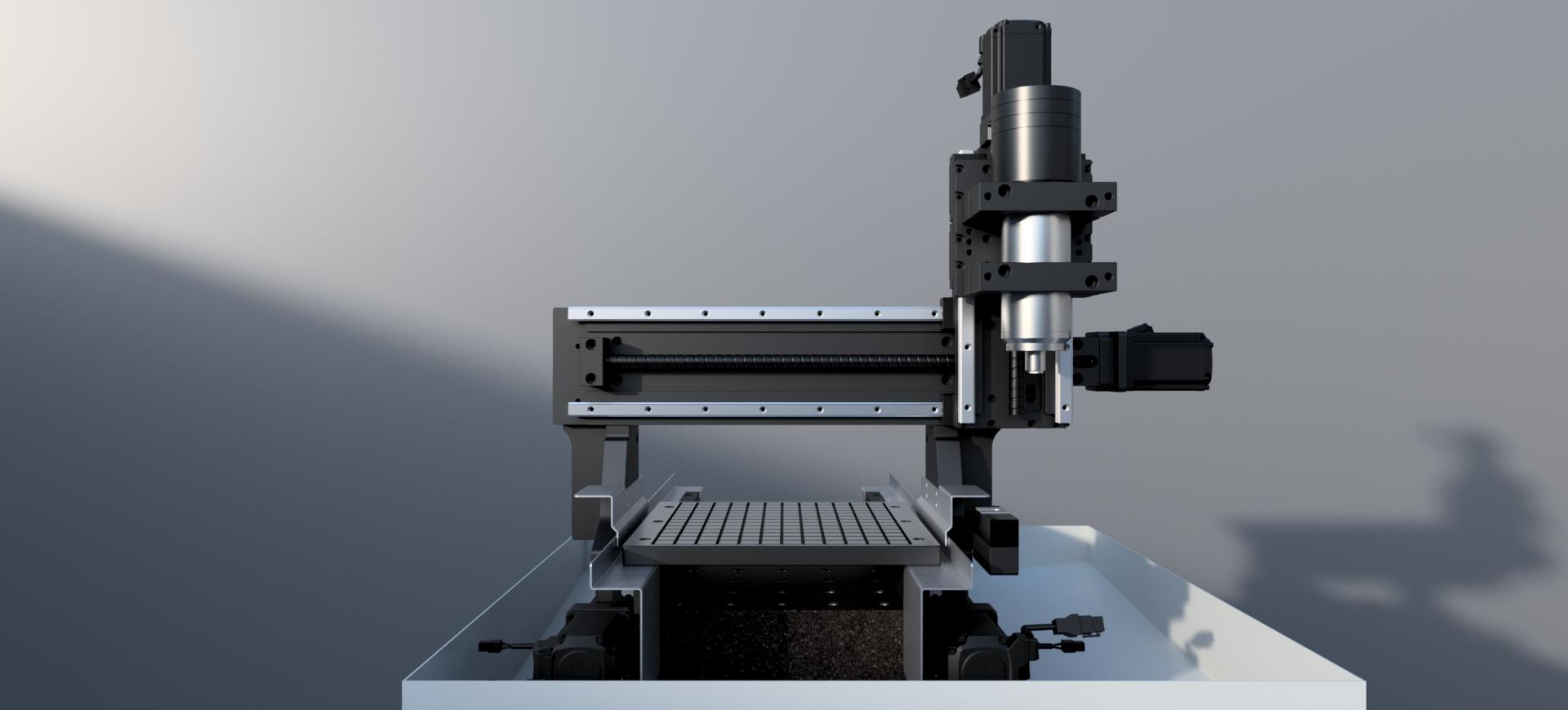

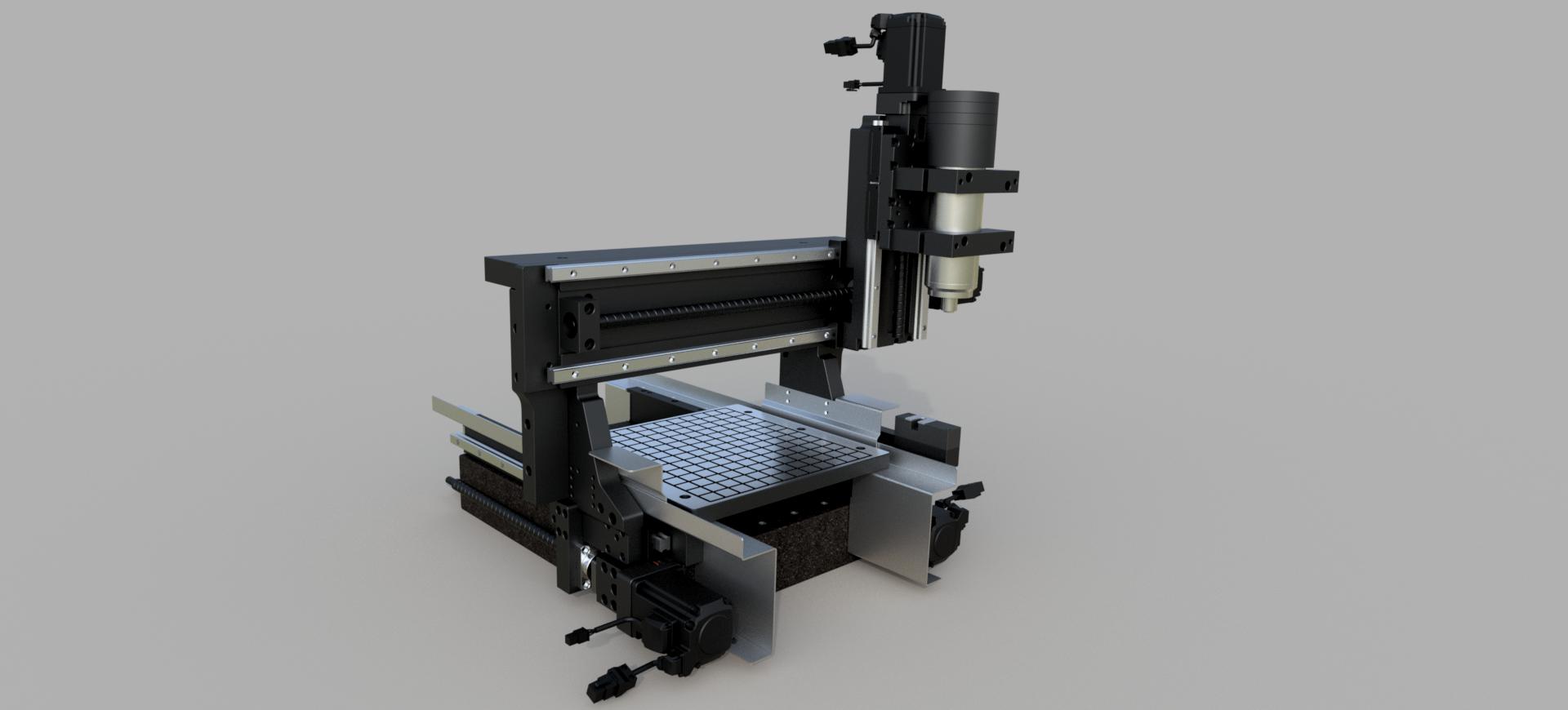

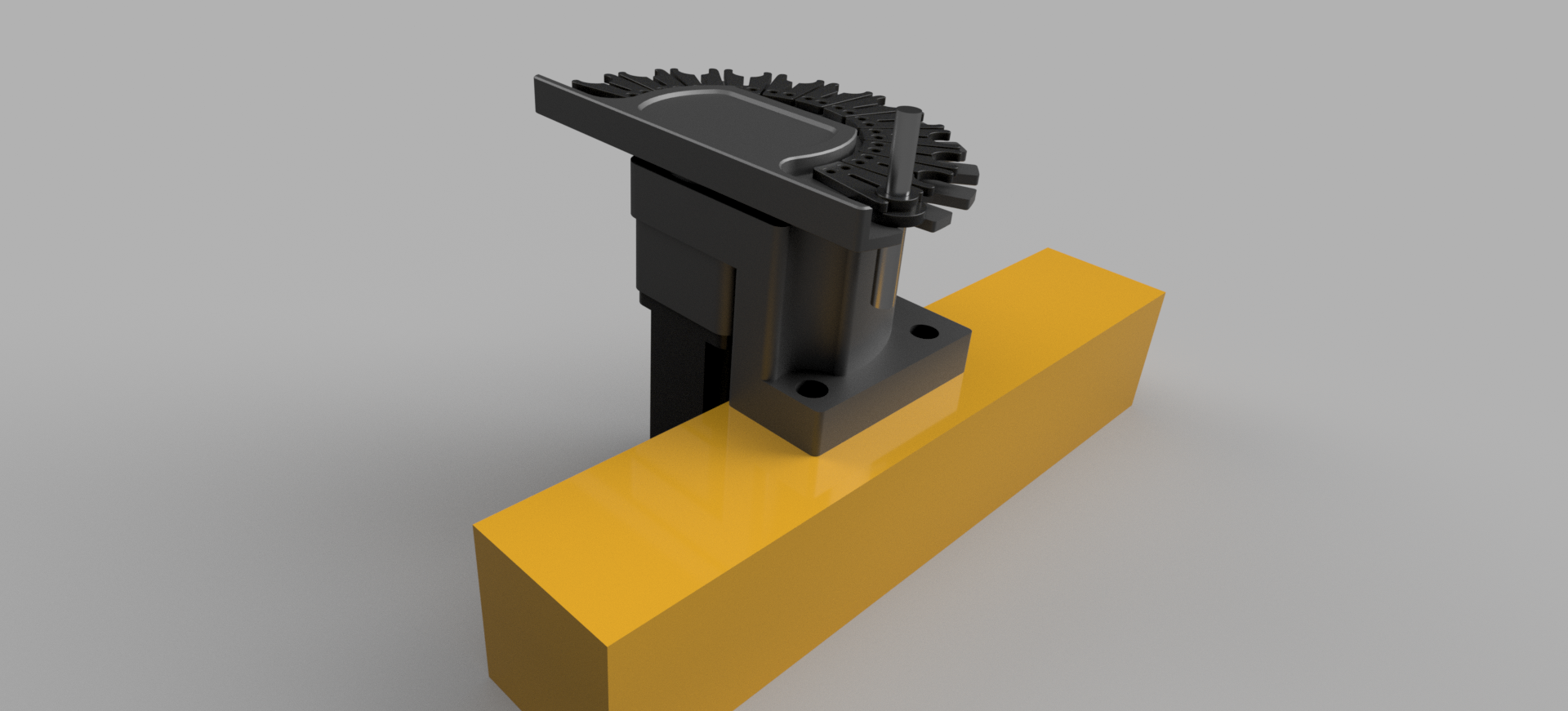

Hmmm. I might be able to SLS print the way covers from nylon. Looking like around $400-$500cdn shipped for the X axis in the render. That probably cheaper and better than anything else except bellows which are cheap but terrible. Only downside is you don't have a super smooth surface for the wiper seal, but maybe a little brush seal might be better anyway.

Probably in the $1500cdn area for all covers on the machine. Plus another $500 for a printed tool magazine.

And then if a customer smashes a part, they can just print a new one. Very plausible.

Probably in the $1500cdn area for all covers on the machine. Plus another $500 for a printed tool magazine.

And then if a customer smashes a part, they can just print a new one. Very plausible.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

03 Jul 2024 01:05 #304287

by tommylight

Replied by tommylight on topic Mini wannabe datron build

Is that quote from the likes of PCBWay and JLCPCB, or ?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

03 Jul 2024 01:25 - 03 Jul 2024 01:25 #304288

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

JLC yes. No one else is even close to that cheap on large nylon parts.

Last edit: 03 Jul 2024 01:25 by ihavenofish.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

03 Jul 2024 19:59 #304340

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

04 Jul 2024 21:29 - 04 Jul 2024 21:29 #304429

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

vroom

Last edit: 04 Jul 2024 21:29 by ihavenofish.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

05 Jul 2024 23:49 #304506

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

So this was a total screw up so I edited it into a little art film.

Demonstrates the need for jerk control!

Demonstrates the need for jerk control!

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 946

- Thank you received: 233

15 Jul 2024 07:03 #305205

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

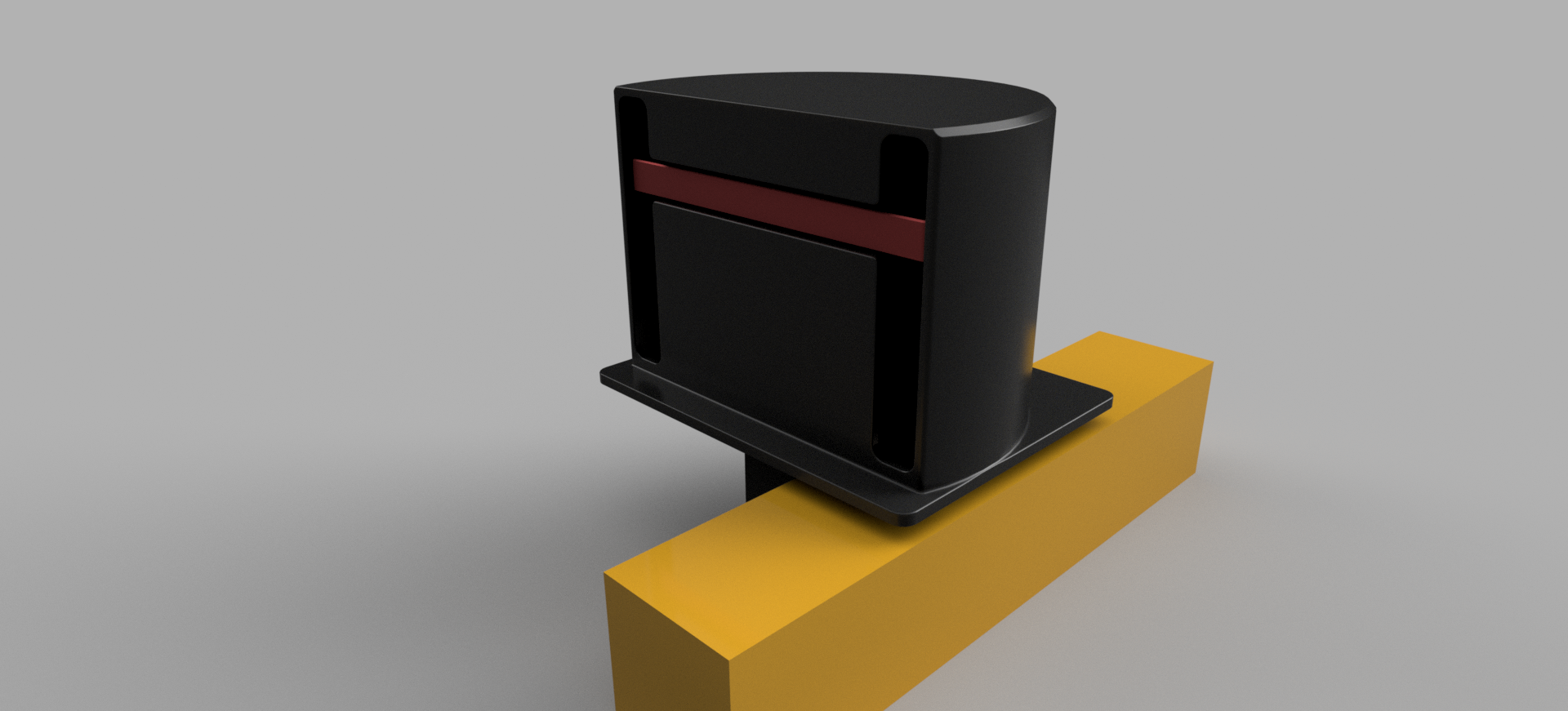

Tool mag for the direct collet spindle on the prototype machine.

Seems pretty easy. I want to use one of the little 100w lichuan ethercat servos with absolute encoder.

In my head this should basically work the same as a static tray atc, commanding the magazine to rotate as a W axis to a position from an o-sub.

Seems pretty easy. I want to use one of the little 100w lichuan ethercat servos with absolute encoder.

In my head this should basically work the same as a static tray atc, commanding the magazine to rotate as a W axis to a position from an o-sub.

Attachments:

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.340 seconds