Biesse Rover 346 Retrofit

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

11 Feb 2017 05:37 #87800

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

Thanks Todd, Thats what I needed,

I will work on that.

I will work on that.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

11 Feb 2017 06:56 - 11 Feb 2017 07:02 #87802

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

Still cant get a handle on it.

I am using motion.spindle-speed-out sending 0-10 to the spindle inverter.

But this says the analog in is an out pin....

BS_346.hal:224: Signal 'spindle-speed-DAC' can not add OUT pin 'hm2_5i25.0.7i77.0.0.analogin0', it already has OUT pin 'scale.0.out'

INI file:

#********************

# Spindle

#********************

[SPINDLE_9]

OUTPUT_SCALE = 24000

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 24000

I am at a loss.

# BS_346 Wood Router 1 08:35:01 2017

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=200xxx sserial_port_1=00000000"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z

loadrt classicladder_rt

addf classicladder.0.refresh servo-thread

loadusr classicladder MotionSP1.clp

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# JOINT X

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [JOINT_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [JOINT_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [JOINT_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd joint.0.motor-pos-cmd

net x-enable joint.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => joint.0.motor-pos-fb

net x-index-enable joint.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

net x-home-sw => hm2_5i25.0.7i70.1.0.input-45-not

#*******************

# JOINT Y

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [JOINT_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [JOINT_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [JOINT_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout1

net y-pos-cmd joint.1.motor-pos-cmd

net y-enable joint.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [JOINT_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.01.position

net y-vel-fb <= hm2_5i25.0.encoder.01.velocity

net y-pos-fb => joint.1.motor-pos-fb

net y-index-enable joint.1.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

net y-home-sw => hm2_5i25.0.7i70.1.0.input-46-not

#*******************

# JOINT Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [JOINT_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [JOINT_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [JOINT_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout2

net z-pos-cmd joint.2.motor-pos-cmd

net z-enable joint.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [JOINT_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.02.position

net z-vel-fb <= hm2_5i25.0.encoder.02.velocity

net z-pos-fb => joint.2.motor-pos-fb

net z-index-enable joint.2.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

net z-home-sw => hm2_5i25.0.7i70.1.0.input-47

#*******************

# SPINDLE S

#*******************

# --- Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-on-1 motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-speed-scale motion.spindle-speed-out hm2_5i25.0.7i77.0.1.analogout5

#********************************

# === Analog input scaling ===

#********************************

loadrt scale count=1

addf scale.0 servo-thread

setp scale.0.gain 0.002

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => hm2_5i25.0.7i77.0.0.analogin0

#loadrt near

#addf near.0 servo-thread

#net spindle-cmd near.0.in1

#net spindle-velocity near.0.in2

#net spindle-at-speed motion.spindle-at-speed <= near.0.out

#setp near.0.scale 1.01

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# END Analog Input Scaling

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

#net spindle-vel-cmd-rpm =>

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

#net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

#net spindle-enable <= motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

#sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

I am using motion.spindle-speed-out sending 0-10 to the spindle inverter.

But this says the analog in is an out pin....

BS_346.hal:224: Signal 'spindle-speed-DAC' can not add OUT pin 'hm2_5i25.0.7i77.0.0.analogin0', it already has OUT pin 'scale.0.out'

INI file:

#********************

# Spindle

#********************

[SPINDLE_9]

OUTPUT_SCALE = 24000

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 24000

I am at a loss.

Warning: Spoiler!

# BS_346 Wood Router 1 08:35:01 2017

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=200xxx sserial_port_1=00000000"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z

loadrt classicladder_rt

addf classicladder.0.refresh servo-thread

loadusr classicladder MotionSP1.clp

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# JOINT X

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [JOINT_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [JOINT_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [JOINT_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd joint.0.motor-pos-cmd

net x-enable joint.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => joint.0.motor-pos-fb

net x-index-enable joint.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

net x-home-sw => hm2_5i25.0.7i70.1.0.input-45-not

#*******************

# JOINT Y

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [JOINT_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [JOINT_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [JOINT_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout1

net y-pos-cmd joint.1.motor-pos-cmd

net y-enable joint.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [JOINT_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.01.position

net y-vel-fb <= hm2_5i25.0.encoder.01.velocity

net y-pos-fb => joint.1.motor-pos-fb

net y-index-enable joint.1.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

net y-home-sw => hm2_5i25.0.7i70.1.0.input-46-not

#*******************

# JOINT Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [JOINT_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [JOINT_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [JOINT_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout2

net z-pos-cmd joint.2.motor-pos-cmd

net z-enable joint.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [JOINT_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.02.position

net z-vel-fb <= hm2_5i25.0.encoder.02.velocity

net z-pos-fb => joint.2.motor-pos-fb

net z-index-enable joint.2.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

net z-home-sw => hm2_5i25.0.7i70.1.0.input-47

#*******************

# SPINDLE S

#*******************

# --- Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-on-1 motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-speed-scale motion.spindle-speed-out hm2_5i25.0.7i77.0.1.analogout5

#********************************

# === Analog input scaling ===

#********************************

loadrt scale count=1

addf scale.0 servo-thread

setp scale.0.gain 0.002

net spindle-speed-scale motion.spindle-speed-out => scale.0.in

net spindle-speed-DAC scale.0.out => hm2_5i25.0.7i77.0.0.analogin0

#loadrt near

#addf near.0 servo-thread

#net spindle-cmd near.0.in1

#net spindle-velocity near.0.in2

#net spindle-at-speed motion.spindle-at-speed <= near.0.out

#setp near.0.scale 1.01

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# END Analog Input Scaling

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

#net spindle-vel-cmd-rpm =>

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

#net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

#net spindle-enable <= motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

#sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Last edit: 11 Feb 2017 07:02 by bevins.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

11 Feb 2017 14:32 #87820

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 346 Retrofit

The scaling of RPM to 10v for the spindle speed command out is done in the mesa hardware. That is set by the SPINDLE_9]OUTPUT_SCALE value from your ini file.

The scale for your analog input spindle speed feed back may or may not be the same. (The actual numbers may be quite different.)

Here is an idea of what I think you need to try.

(no guarantees there are no mistakes in this.)

The scale for your analog input spindle speed feed back may or may not be the same. (The actual numbers may be quite different.)

Here is an idea of what I think you need to try.

(no guarantees there are no mistakes in this.)

#*******************

# SPINDLE S

#*******************

# --- Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-on-1 <= motion.spindle-on => hm2_5i25.0.7i77.0.1.spinena

net spindle-vel-cmd-rpm <= motion.spindle-speed-out => hm2_5i25.0.7i77.0.1.analogout5

#********************************

# === Analog input scaling ===

#********************************

loadrt scale count=1 #I would suggest moving this line to the top of the hal file with the other loadrt commands

addf scale.0 servo-thread #I would suggest moving these lines to the top of the hal file with the other addf commands

setp scale.0.gain 0.002 #You may have to experiment with this value to get scale.0.out to sort of match motion.spindle-speed-out.

#It may or may not be approximately the same as or the inverse of [SPINDLE_9]OUTPUT_SCALE

net spindle-speed-DAC <= hm2_5i25.0.7i77.0.0.analogin0 => scale.0.in

net spindle-feedback <= scale.0.out

loadrt near count=1 #I would suggest moving this line to the top of the hal file with the other loadrt commands

addf near.0 servo-thread #I would suggest moving these lines to the top of the hal file with the other addf commands

setp near.0.scale 1.01 #You may have to play with this number to fine tune it.

net spindle-vel-cmd-rpm => near.0.in1

net spindle-feedback => near.0.in2

net spindle-at-speed <= near.0.out

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# END Analog Input Scaling

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

#net spindle-vel-cmd-rpm =>

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

#net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

#net spindle-enable <= motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

#sets spindle-at-speed true

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

11 Feb 2017 18:14 - 11 Feb 2017 18:17 #87831

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

I think I have it setup properly, but spindle-at-speed never goes true, so the program doesnt continue.

It is really close.......

Tried tweaking the near scale up and down but nothing yet.

Both analogout and analog in are the same so it should set spindle-at-speed true I would think.

It is really close.......

Tried tweaking the near scale up and down but nothing yet.

Both analogout and analog in are the same so it should set spindle-at-speed true I would think.

Warning: Spoiler!

#*******************

# SPINDLE S

#*******************

# --- Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-on-1 motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

#net spindle-speed-scale motion.spindle-speed-out hm2_5i25.0.7i77.0.1.analogout5

net spindle-vel-cmd-rpm <= motion.spindle-speed-out => hm2_5i25.0.7i77.0.1.analogout5

#********************************

# === Analog input scaling ===

#********************************

setp scale.0.gain 0.102

net spindle-speed-DAC <= hm2_5i25.0.7i77.0.0.analogin0 => scale.0.in

net spindle-feedback <= scale.0.out

setp near.0.scale 2.01

net spindle-vel-cmd-rpm => near.0.in1

net spindle-feedback => near.0.in2

net spindle-at-speed <= motion.spindle-at-speed near.0.out

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# END Analog Input Scaling

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

#net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

#net spindle-enable <= motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

#net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

#sets spindle-at-speed true

# SPINDLE S

#*******************

# --- Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout5-scalemax [SPINDLE_9]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout5-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout5-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

net spindle-on-1 motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

#net spindle-speed-scale motion.spindle-speed-out hm2_5i25.0.7i77.0.1.analogout5

net spindle-vel-cmd-rpm <= motion.spindle-speed-out => hm2_5i25.0.7i77.0.1.analogout5

#********************************

# === Analog input scaling ===

#********************************

setp scale.0.gain 0.102

net spindle-speed-DAC <= hm2_5i25.0.7i77.0.0.analogin0 => scale.0.in

net spindle-feedback <= scale.0.out

setp near.0.scale 2.01

net spindle-vel-cmd-rpm => near.0.in1

net spindle-feedback => near.0.in2

net spindle-at-speed <= motion.spindle-at-speed near.0.out

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# END Analog Input Scaling

#%%%%%%%%%%%%%%%%%%%%%%%%%%%

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

#net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

#net spindle-enable <= motion.spindle-on hm2_5i25.0.7i77.0.1.spinena

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

#net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

#sets spindle-at-speed true

Last edit: 11 Feb 2017 18:17 by bevins.

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

11 Feb 2017 19:25 #87835

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

12 Feb 2017 02:26 - 12 Feb 2017 03:16 #87852

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

The spindle output 0-10 is being scaled by the board but it is going from rpm (gcode) to analogout 0-10.

I need analog in so it has to be reverse scaling so:

The scaling the other way is 10/24000 should be the gain. Thats going from rpm to analogout 0-10

so my calculations are it should be the other way around for 0-10 to rpm which should be something like:

10 X 24000 = the gain

Does this logic make sense?

/EDIT Apparantly not. Doesnt work. I am all out of ideas.

I need analog in so it has to be reverse scaling so:

The scaling the other way is 10/24000 should be the gain. Thats going from rpm to analogout 0-10

so my calculations are it should be the other way around for 0-10 to rpm which should be something like:

10 X 24000 = the gain

Does this logic make sense?

/EDIT Apparantly not. Doesnt work. I am all out of ideas.

Last edit: 12 Feb 2017 03:16 by bevins.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

12 Feb 2017 04:41 - 12 Feb 2017 04:44 #87857

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 346 Retrofit

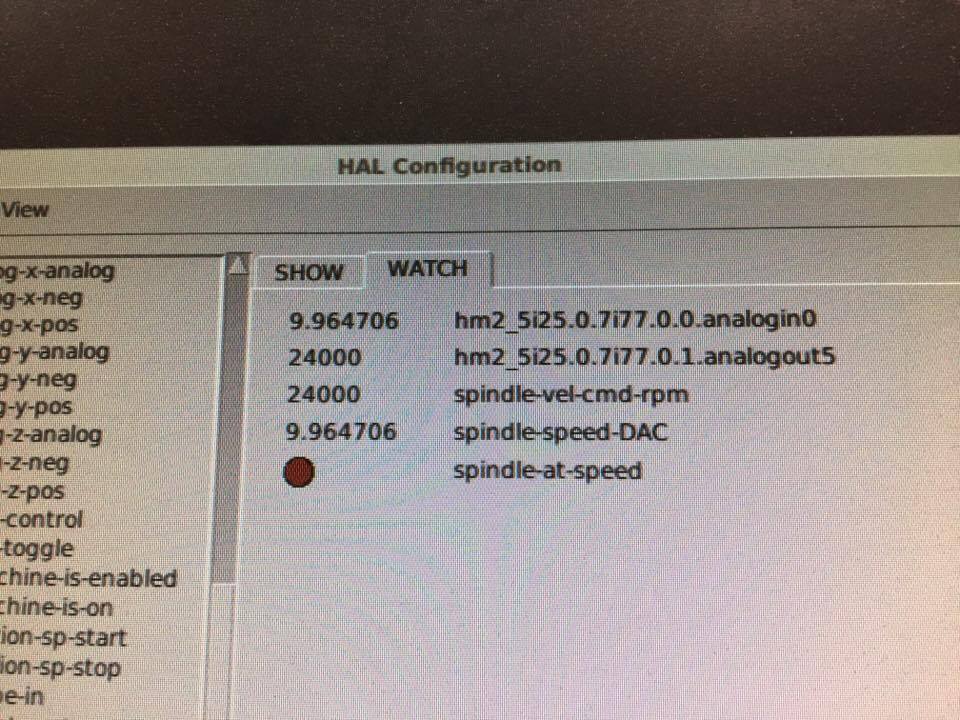

What you need to do is scale the analogin to match your RPM. That is what the scale component we added is for. Use the setp scale.0.gain to set that and from the images you posted from the pins watched it should be about 2400 (not 0.102)

setp scale.0.gain 2400

You'll probably want to make the near scale closer to 1 but I have never used a near comp.

setp scale.0.gain 2400

You'll probably want to make the near scale closer to 1 but I have never used a near comp.

Last edit: 12 Feb 2017 04:44 by Todd Zuercher.

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

12 Feb 2017 13:29 #87868

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

The spindle-at-speed saga is finished. It is working somewhat.

It is not linear so the farther away you get from the max the more the difference is. There is a tradeoff. I cannot get 1000 RPM because I would have to set the near scale to 3.5 but then if I request 24000 it will be spindle at speed at like 6000 RPM. I can live with this for now. Will never have the spindle at 1000 rpm. Wood routers are not ideal at 1000 rpm.

Thank you Todd for your help with this. I learned alot and it will be a long time before I forget this one. Helps with all the other comps....

So the machine is up and running. Theoretically I could be cutting some wood now. Have to work out the spindle selects, and start thinking about the tool changer, and of course the control panel.

on with the show.........

NEXT!!!

It is not linear so the farther away you get from the max the more the difference is. There is a tradeoff. I cannot get 1000 RPM because I would have to set the near scale to 3.5 but then if I request 24000 it will be spindle at speed at like 6000 RPM. I can live with this for now. Will never have the spindle at 1000 rpm. Wood routers are not ideal at 1000 rpm.

Thank you Todd for your help with this. I learned alot and it will be a long time before I forget this one. Helps with all the other comps....

So the machine is up and running. Theoretically I could be cutting some wood now. Have to work out the spindle selects, and start thinking about the tool changer, and of course the control panel.

on with the show.........

NEXT!!!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

12 Feb 2017 20:23 #87885

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 346 Retrofit

Perhaps you need to set this pin "near.0.difference" to something.other than the default of 0. and keep "near.0.scale" closer to 1.

setp near.0.difference 500

You might also need to fine tune "scale.0.gain" and "scale.0.offset" a little better..

setp near.0.difference 500

You might also need to fine tune "scale.0.gain" and "scale.0.offset" a little better..

The following user(s) said Thank You: bevins

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

13 Feb 2017 23:43 #87931

by bevins

Replied by bevins on topic Biesse Rover 346 Retrofit

Everything working great so far. Doing some logic with ClassicLadder.

I have a 12 foot table. I need to know when the cnc goes past 6 foot and again when it comes back across the 6 foot mark.

Is there a way to do this or does code have to be written?

Can someone give me a hint?

Thanks,

bob

I have a 12 foot table. I need to know when the cnc goes past 6 foot and again when it comes back across the 6 foot mark.

Is there a way to do this or does code have to be written?

Can someone give me a hint?

Thanks,

bob

Please Log in or Create an account to join the conversation.

Time to create page: 0.211 seconds