Multiple tools on the CNC

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

25 Apr 2019 23:48 #131903

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

I also have a setup like this, in the form of a old Busellato joinery machine. It also has sixteen drills, plus three spindles, where each tool is actuated pneumatically. As with Peter's set-up, all the drills are ganged, via an internal gear-train, but the three separate spindles share the same VFD - switched in by relay as required.

I was thinking I would have to remap the tool-change codes, but if I can achieve the same in the HAL config, I think that would be so much easier!

The issue I see is that for T1-16, the drilling motor needs to be switched on. (There is a physical signal connection within the control cab that inhibits the VFD when drilling motor is on.)

For the spindles, need to confirm 0rpm (there is an signal output from VFD), THEN disengage previous tool (I guess LCNC does that automatically?), THEN actuate pneumatic and switch VFD to new tool and apply tool offsets. I think for my purposes the pneumatic and spindle relay signals could be ganged.

Is it possible to do this in HAL?

Todd: could you please provide the link to this discussion - I haven't mananged to find that one, only this post.Custom m codes isn't the only way this can be done. There was a discussion here a few weeks ago that talked about multiple ways to do this.

I was thinking I would have to remap the tool-change codes, but if I can achieve the same in the HAL config, I think that would be so much easier!

The issue I see is that for T1-16, the drilling motor needs to be switched on. (There is a physical signal connection within the control cab that inhibits the VFD when drilling motor is on.)

For the spindles, need to confirm 0rpm (there is an signal output from VFD), THEN disengage previous tool (I guess LCNC does that automatically?), THEN actuate pneumatic and switch VFD to new tool and apply tool offsets. I think for my purposes the pneumatic and spindle relay signals could be ganged.

Is it possible to do this in HAL?

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

26 Apr 2019 02:01 #131918

by Todd Zuercher

Replied by Todd Zuercher on topic Multiple tools on the CNC

Personally I would probably do the logic with Classicladder, mostly because I'm comfortable with plc logic.

Not sure what solution the fellow trying to use 40 spindles choose. Think he was looking at using remapping. I preferred doing it with a custom mcode with a P binary number term to choose which spindle(s) were engaged. I tested the Mcode with up 45 and it worked.

Here is the thread in question.

forum.linuxcnc.org/38-general-linuxcnc-q...ine-with-45-spindles

Not sure what solution the fellow trying to use 40 spindles choose. Think he was looking at using remapping. I preferred doing it with a custom mcode with a P binary number term to choose which spindle(s) were engaged. I tested the Mcode with up 45 and it worked.

Here is the thread in question.

forum.linuxcnc.org/38-general-linuxcnc-q...ine-with-45-spindles

The following user(s) said Thank You: HueyHQ

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

26 Apr 2019 06:43 #131929

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

Whoa! 40 drills! Makes mine look like child's play!

Thanks Todd - I had a look at your 40drills.zip file, and I think my solution will be simpler as I will only ever use it as a single tool at a time. If I change my mind in the future, I'll know where to look!

Do you have an example of using ClassicLadder for my situation? I've looked at it, and it confused the hell out of me! I'm sure if I just jumped into the deep-end, it might click.

Of both ClassicLadder and remapping, I thought remapping looked easier. And I don't even know Python either, but figured I could work it out quicker than Ladder!

Thanks Todd - I had a look at your 40drills.zip file, and I think my solution will be simpler as I will only ever use it as a single tool at a time. If I change my mind in the future, I'll know where to look!

Do you have an example of using ClassicLadder for my situation? I've looked at it, and it confused the hell out of me! I'm sure if I just jumped into the deep-end, it might click.

Of both ClassicLadder and remapping, I thought remapping looked easier. And I don't even know Python either, but figured I could work it out quicker than Ladder!

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

26 Apr 2019 08:09 #131932

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

So there are several ways to solve this. Either by M-code + classic ladder or by the Hal file.

But when I want to use Fusion 360 and the LinuxCNC postprocessor, I think the only way to go is the Hal file.

As far as I know, the Fusion post processor generates a T-code for tool change an no M-code.

I would be nice to have a CNC file generated by Fusion, that is usable in LinuxCNC without manual changes afterwards.

But when I want to use Fusion 360 and the LinuxCNC postprocessor, I think the only way to go is the Hal file.

As far as I know, the Fusion post processor generates a T-code for tool change an no M-code.

I would be nice to have a CNC file generated by Fusion, that is usable in LinuxCNC without manual changes afterwards.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

26 Apr 2019 12:26 #131945

by Todd Zuercher

Replied by Todd Zuercher on topic Multiple tools on the CNC

One of the most common uses of these multi spindle drilling heads on wood routers is for drilling rows of evenly spaced holes for adjustable shelving in cabinets. For this reason it is often important to have the option of using more than one drill at a time on these wood routers. But If you don't see yourself ever using them this way fine. But it can cut huge amounts of time off of a run when you can.

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

26 Apr 2019 21:35 #132022

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

Yeah, exactly. But the number of times I see myself making a set of shelves is about zero! If I ever do end up making an adjustable shelf unit, I can probably afford the extra few minutes!

But I'm hearing ya; if I ever end up manufacturing shelf units, I can always reconfigure.

But I'm hearing ya; if I ever end up manufacturing shelf units, I can always reconfigure.

Please Log in or Create an account to join the conversation.

- Chathuranga555

-

- Visitor

-

03 May 2019 03:32 #132593

by Chathuranga555

Replied by Chathuranga555 on topic Multiple tools on the CNC

I have the same Busellato machine and the controller isnt working properly. what are the mesa cards used for retrofit your machine?

Is it working properly?

Is it working properly?

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

03 May 2019 21:02 #132666

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

I can't tell you, because I've ordered the Mesa 5i25 and 7i77 5 weeks ago, but still not delivered  . I think they are unavailable at this moment.

. I think they are unavailable at this moment.

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

04 May 2019 00:23 #132676

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

Yes, I bought the Mesa 5i25/7i77 Plug 'n' Go kit, and they work great out of the box!

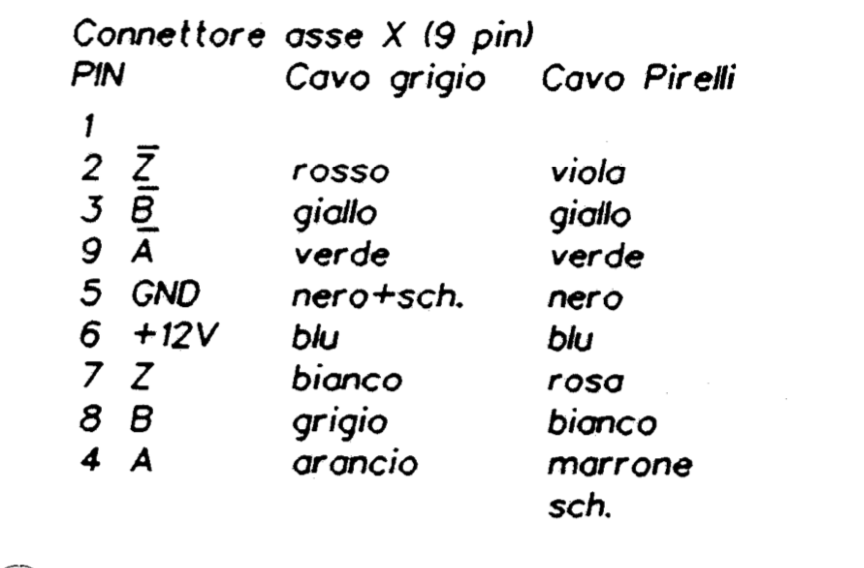

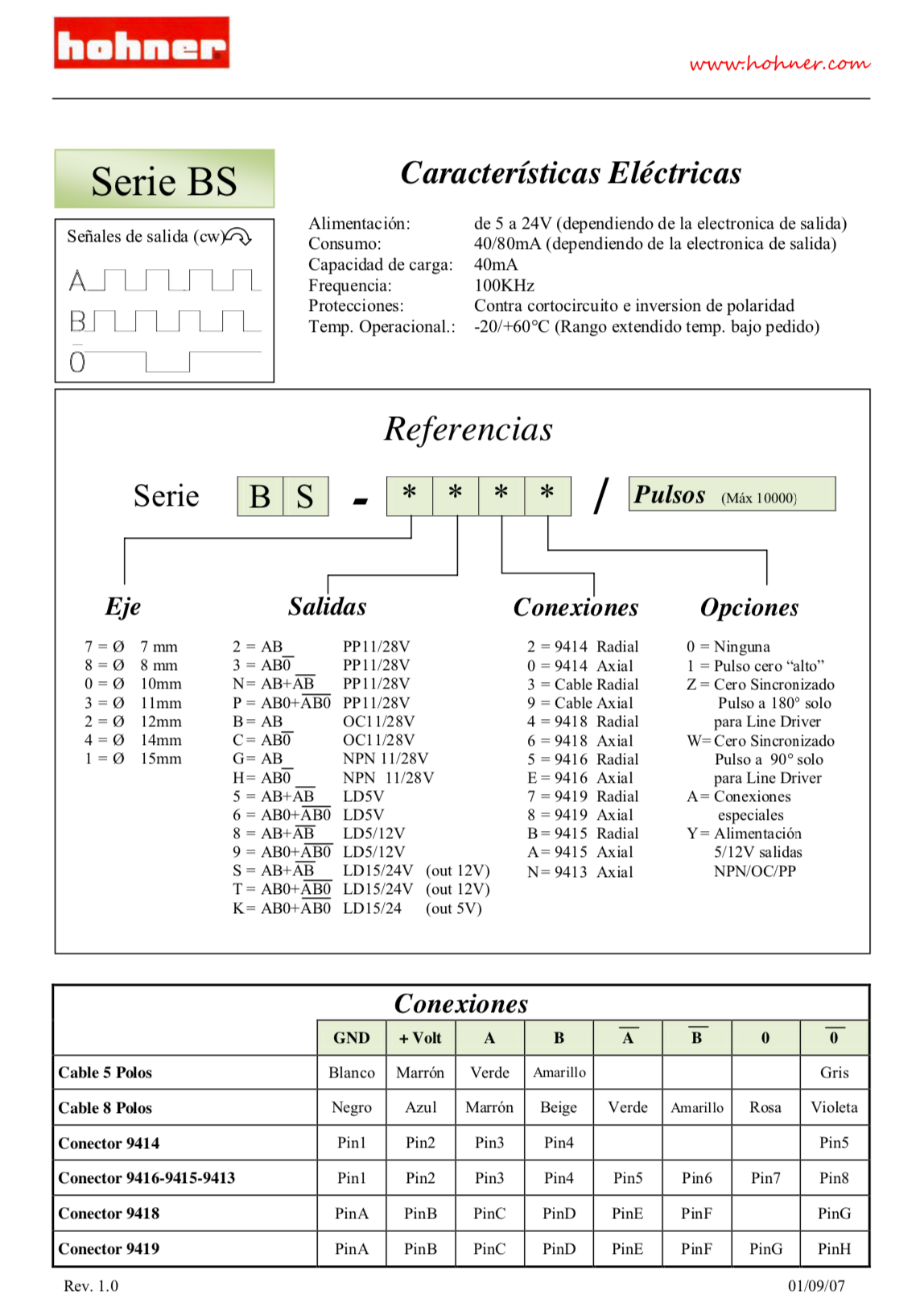

My biggest problem has been the encoders - the original Lika encoders were 12V supply and 12V single-ended output; the 7i77 provides 5V and expects 5V. I was going to provide 12V externally then opto-shift the output to 5V, but then I broke one of them and decided to replace all 3 to work with the 7i77, and take advantage of differential signals with index (not necessary though). I've had a mixed bag of success with encoders bought off eBay, but I think I'm at a point to start tuning the servos. I'll start with a single spindle as I work out how to control the multiple heads.

I'm really new to this but willing to help out with what I've learned so far!

My biggest problem has been the encoders - the original Lika encoders were 12V supply and 12V single-ended output; the 7i77 provides 5V and expects 5V. I was going to provide 12V externally then opto-shift the output to 5V, but then I broke one of them and decided to replace all 3 to work with the 7i77, and take advantage of differential signals with index (not necessary though). I've had a mixed bag of success with encoders bought off eBay, but I think I'm at a point to start tuning the servos. I'll start with a single spindle as I work out how to control the multiple heads.

I'm really new to this but willing to help out with what I've learned so far!

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

04 May 2019 08:19 #132708

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

Please Log in or Create an account to join the conversation.

Time to create page: 0.313 seconds