Multiple tools on the CNC

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

04 May 2019 09:03 #132709

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

I would make sure the output signal is 5V, as I think the 7i77 encoder input is not tolerant to much different. That was my interpretation of the specs, but you might want to check yourself. I think you can put a multimeter across an A or B differential pair with the 12V applied to check.

Not sure if this is what you're asking for, but for connection:

Not sure if this is what you're asking for, but for connection:

| 7i77 | <- | Encoder |

| 8 | /Z | |

| 7 | Z | |

| 6 | VCC | |

| 5 | /B | |

| 4 | B | |

| 3 | GND and Shield | |

| 2 | /A | |

| 1 | A |

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

04 May 2019 09:27 #132710

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

As far as I could find in documentation, the BS193/500 encoder works between 5 and 24V. But I can check if the encoder works with 5V supplied.

To check this, I simply has to provide 5V to pin 3 and 6, and measure if I see 5V between pin 1 and 2 while turning the encoder?

To check this, I simply has to provide 5V to pin 3 and 6, and measure if I see 5V between pin 1 and 2 while turning the encoder?

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

04 May 2019 09:40 #132711

by HueyHQ

Replied by HueyHQ on topic Multiple tools on the CNC

With 5V, I think you would be fairly safe!

Your check sounds right, just watch your pin-outs - you've referenced the Mesa pins, not the encoder pins?

Your check sounds right, just watch your pin-outs - you've referenced the Mesa pins, not the encoder pins?

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

04 May 2019 09:44 #132713

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

I could use the 5V provided by the Mesa (pin 3 and 6) and then check the output pins on the encoder (pin 1 and 2) if I get 5V pulses.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 May 2019 10:30 - 04 May 2019 11:27 #132717

by bevins

Replied by bevins on topic Multiple tools on the CNC

Hi all,

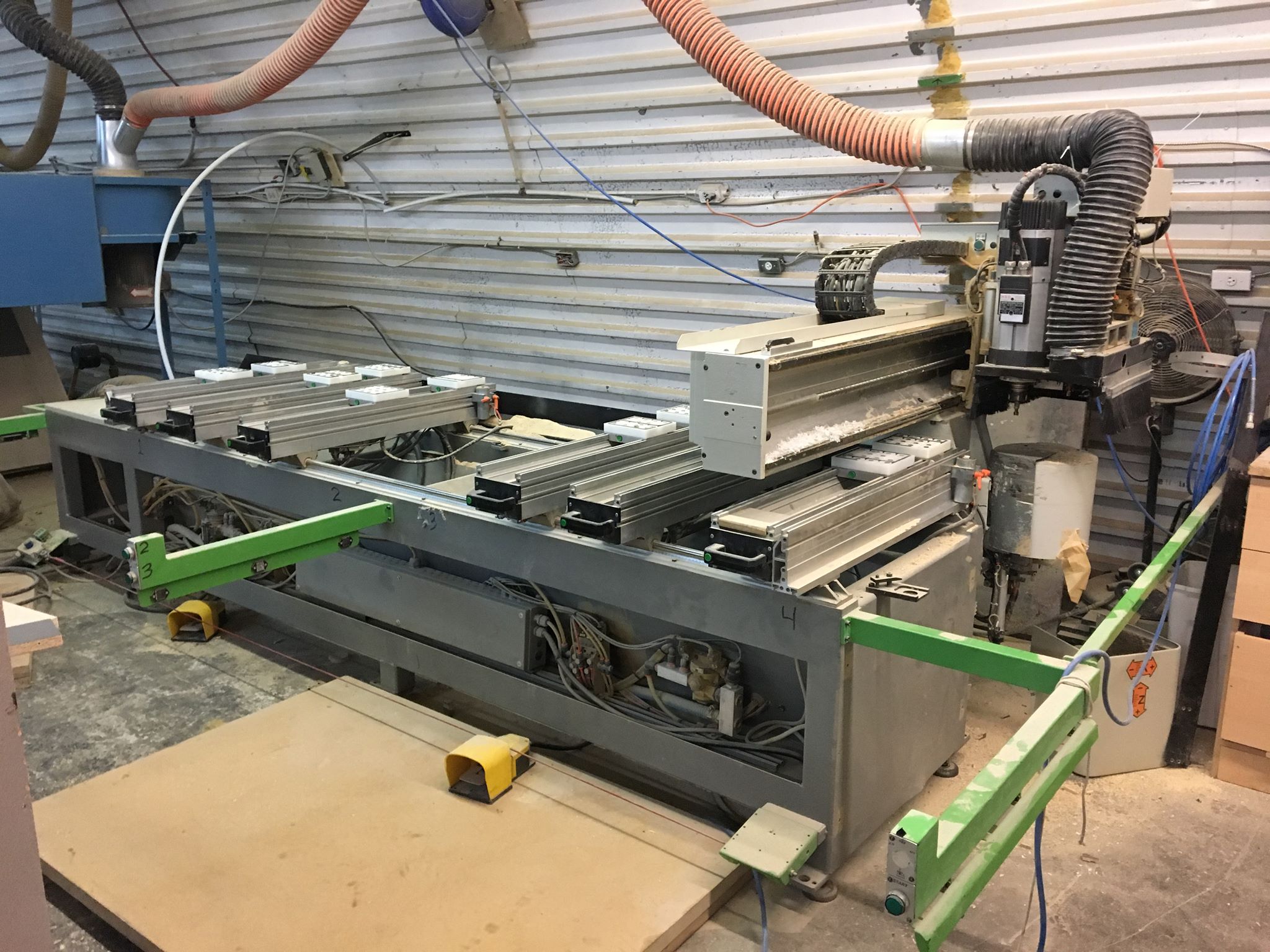

I have a Biesse Rover 346 with 40 drills and three spindles. I went with remapping M6 in python.

The code for my Biesse remapping is here. Biesse Rover 346 remap[ M6 in python

The machine is currently in production. All works including all side drillls, spindles and side aggregate for horizontal milling.

The Rover 18 I dont think has a tool changer. This would be kinda easy with a remap.

I have three spindles and one VFD and route the VFD signals through a contactor along with a spindle selector contactor so whatever spindle I command, I energize the contactor. For the gang drills, you need to energize the motor in the remap instead of the spindle, depending on tool_selected. So you should send your three wires going to your spindle through a contactor and you can select spindle or gang drill motor in the remap. Also because m3 is controlling the spindle, you need to shut off the gang motor when you get M5. I chose to remap M200, this shuts off gang motor and raises all tools and spindles.

One other thing is the pre logic for the Biesse, thermic switches, air etc... needs to be clear before you get a green lite. I left that logic there and ran the estop through that logic. So when power up, you use the same step, to get the green lite on the Biesse before you can clear the estop. IT works well.

Rover 20 in the shop about to do a retrofit on.

My Biesse Rover 346

I have a Biesse Rover 346 with 40 drills and three spindles. I went with remapping M6 in python.

The code for my Biesse remapping is here. Biesse Rover 346 remap[ M6 in python

The machine is currently in production. All works including all side drillls, spindles and side aggregate for horizontal milling.

The Rover 18 I dont think has a tool changer. This would be kinda easy with a remap.

I have three spindles and one VFD and route the VFD signals through a contactor along with a spindle selector contactor so whatever spindle I command, I energize the contactor. For the gang drills, you need to energize the motor in the remap instead of the spindle, depending on tool_selected. So you should send your three wires going to your spindle through a contactor and you can select spindle or gang drill motor in the remap. Also because m3 is controlling the spindle, you need to shut off the gang motor when you get M5. I chose to remap M200, this shuts off gang motor and raises all tools and spindles.

One other thing is the pre logic for the Biesse, thermic switches, air etc... needs to be clear before you get a green lite. I left that logic there and ran the estop through that logic. So when power up, you use the same step, to get the green lite on the Biesse before you can clear the estop. IT works well.

Rover 20 in the shop about to do a retrofit on.

My Biesse Rover 346

Attachments:

Last edit: 04 May 2019 11:27 by bevins.

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

04 May 2019 10:43 #132720

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

This is amazing begins  great work !!!

great work !!!

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 May 2019 11:10 #132724

by bevins

Supply them 5v and they should work. My experience 12v encoders will work with 5V. I did it on a Buseletto.

Replied by bevins on topic Multiple tools on the CNC

I would make sure the output signal is 5V, as I think the 7i77 encoder input is not tolerant to much different. That was my interpretation of the specs, but you might want to check yourself. I think you can put a multimeter across an A or B differential pair with the 12V applied to check.

Not sure if this is what you're asking for, but for connection:

7i77 <- Encoder 8 /Z 7 Z 6 VCC 5 /B 4 B 3 GND and Shield 2 /A 1 A

Supply them 5v and they should work. My experience 12v encoders will work with 5V. I did it on a Buseletto.

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

04 May 2019 11:26 #132725

by Peterdeleu

Replied by Peterdeleu on topic Multiple tools on the CNC

As you may know already, I'm new into this, but I like to learn  .

.

Is this correct?

The encoder get his power from pin 3(-) and pin 6(+)

The result is that there are 5V pulses on A-/A, B-/B and Z-/Z.

Those pulses are is such an order that the Mesa will know the direction and the amount of pulses.

Is this correct?

The encoder get his power from pin 3(-) and pin 6(+)

The result is that there are 5V pulses on A-/A, B-/B and Z-/Z.

Those pulses are is such an order that the Mesa will know the direction and the amount of pulses.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 May 2019 11:36 - 04 May 2019 11:39 #132726

by bevins

Yes that's correct. And you don't have to worry about the mode as it comes default with what you need.

That's the easy part. You can connect the encoders and move the axis by hand and see the encoders counting in hal show.

halshow and halscope are your friends....

Replied by bevins on topic Multiple tools on the CNC

As you may know already, I'm new into this, but I like to learn

.

Is this correct?

The encoder get his power from pin 3(-) and pin 6(+)

The result is that there are 5V pulses on A-/A, B-/B and Z-/Z.

Those pulses are is such an order that the Mesa will know the direction and the amount of pulses.

Yes that's correct. And you don't have to worry about the mode as it comes default with what you need.

That's the easy part. You can connect the encoders and move the axis by hand and see the encoders counting in hal show.

halshow and halscope are your friends....

Last edit: 04 May 2019 11:39 by bevins.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

04 May 2019 11:44 #132727

by bevins

Replied by bevins on topic Multiple tools on the CNC

Another way is to do an ngc M6 remap.

I seen a guy on here remap an mcode for every relay, and in his ngc m6 remap just use mcode for the relay you want to use.

You would have to learn 274ngc language. Its awkward to me and there is no manual that I could find that explains it all so I went with python.

I seen a guy on here remap an mcode for every relay, and in his ngc m6 remap just use mcode for the relay you want to use.

You would have to learn 274ngc language. Its awkward to me and there is no manual that I could find that explains it all so I went with python.

Please Log in or Create an account to join the conversation.

Time to create page: 0.145 seconds