Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

25 May 2024 17:35 #301423

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

i don't, the only way to produce arcs in arbitrary planes i know is the tilted work plane feature (ie G68.x and affiliated gcodes).Do you know if any other control has a paradigm for this? Other than defining ad-hoc planes for each arc, which seems clumsy.

Please Log in or Create an account to join the conversation.

- Ehsan_R

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 1

25 May 2024 20:58 - 25 May 2024 20:59 #301443

by Ehsan_R

Replied by Ehsan_R on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Last edit: 25 May 2024 20:59 by Ehsan_R.

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

26 May 2024 09:16 #301466

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Unfortunately, at the present state, one doesn't seem to get around the math. Which is probably one of the reasons why there tend to be so few people interested in this area of LinuxCNC. Or maybe they just don't bother sharing their work.

Regarding inverse kinematics for manipulator with spherical wrists:

Also helpful are these two documents regarding the Posemath library often used in LinuxCNC.

Note that 'genserkins' seems to be using a different library called 'gomath', if I recall correctly.

Regarding inverse kinematics for manipulator with spherical wrists:

Also helpful are these two documents regarding the Posemath library often used in LinuxCNC.

Note that 'genserkins' seems to be using a different library called 'gomath', if I recall correctly.

Attachments:

The following user(s) said Thank You: DPFlex

Please Log in or Create an account to join the conversation.

- meister

- Offline

- Platinum Member

-

Less

More

- Posts: 706

- Thank you received: 432

27 May 2024 13:39 #301588

by meister

Replied by meister on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

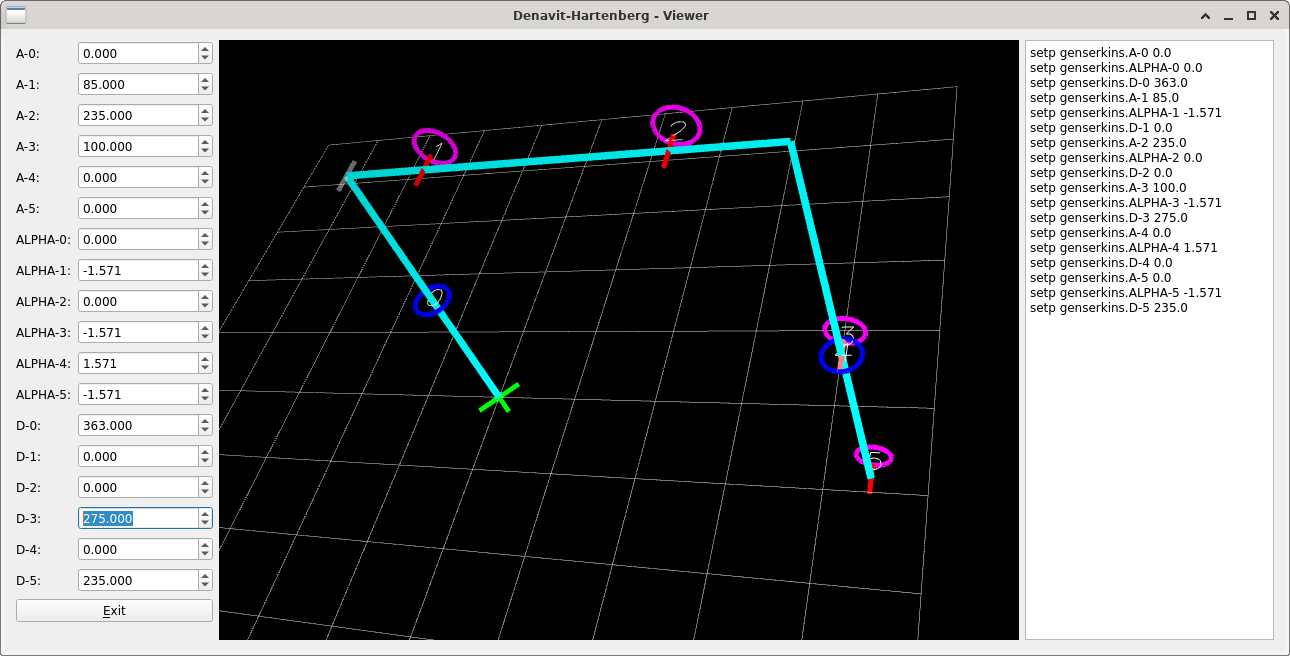

Hi,

because the Denavit-Hartenberg parameters are very difficult for me to adapt to other robots,

I have written a small tool to visualize it.

I'm not sure if it's really correct and if it could help someone.

but it is easier for me to get an understanding of it.

If anyone here is familiar with the parameters, they can take a look at it.

Greetings,

Olli

because the Denavit-Hartenberg parameters are very difficult for me to adapt to other robots,

I have written a small tool to visualize it.

I'm not sure if it's really correct and if it could help someone.

but it is easier for me to get an understanding of it.

If anyone here is familiar with the parameters, they can take a look at it.

Greetings,

Olli

Attachments:

The following user(s) said Thank You: tommylight, Aciera

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

27 May 2024 16:06 #301596

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Looks good, I'd like to have a look at it. Where can I get it from?

Note that 'genserkins' uses a modified Denavit-Hartenberg parameter system. The original system orders the values differently.

Note that 'genserkins' uses a modified Denavit-Hartenberg parameter system. The original system orders the values differently.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

27 May 2024 16:34 #301601

by tommylight

Replied by tommylight on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Probably here

forum.linuxcnc.org/41-guis/52765-linuxcnc-robot-logger

forum.linuxcnc.org/41-guis/52765-linuxcnc-robot-logger

The following user(s) said Thank You: meister, Aciera

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

27 May 2024 17:08 #301606

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Ok, once I figured out that it wants to be pointed to the melfa_dh.hal I got it working.

$ python git/linuxcnc-robot-logger/dh-parameter.py linuxcnc-292-feb/configs/sim/axis/vismach/melfa-sim/melfa_dh.hal

Looks nice.

I don't have much time just now but here is something not quite right in the way the D-parameters are applied. A-offset values are always in the direction of the current X-axis and the D values along the Z-axis. This is correct for A-0,D-0 but the D-1 value is applied in world-x-direction instead of the current-Z-direction (which at this point is pointing in the world-y-direction.)

Have you seen my documentation:

linuxcnc.org/docs/html/motion/dh-parameters.html

$ python git/linuxcnc-robot-logger/dh-parameter.py linuxcnc-292-feb/configs/sim/axis/vismach/melfa-sim/melfa_dh.hal

Looks nice.

I don't have much time just now but here is something not quite right in the way the D-parameters are applied. A-offset values are always in the direction of the current X-axis and the D values along the Z-axis. This is correct for A-0,D-0 but the D-1 value is applied in world-x-direction instead of the current-Z-direction (which at this point is pointing in the world-y-direction.)

Have you seen my documentation:

linuxcnc.org/docs/html/motion/dh-parameters.html

The following user(s) said Thank You: meister

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

27 May 2024 17:12 #301607

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Note that in the 'modified' DH-System the angular rotation (ie 'ALPHA-n') is always applied before the 'A' and 'D'.

IIRC this is different from the standard DH-system.

IIRC this is different from the standard DH-system.

The following user(s) said Thank You: meister

Please Log in or Create an account to join the conversation.

- Ehsan_R

- Offline

- Premium Member

-

Less

More

- Posts: 88

- Thank you received: 1

15 Jun 2024 12:32 #303047

by Ehsan_R

Replied by Ehsan_R on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Hello

How can I increase the speed limit in world coordinates?

And what is your reason for putting this speed limit?

How can I increase the speed limit in world coordinates?

And what is your reason for putting this speed limit?

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

15 Jun 2024 14:07 - 15 Jun 2024 14:08 #303049

by Aciera

Replied by Aciera on topic Mitsubishi RV-6SDL Robot arm Servo/Encoder usability

Speed limits for 'World' and for 'Joint' kinematics mode are set by the [AXIS_l] MAX_VELOCITY values.

The problem here is that in 'Joint' kinematics axis X is a rotational joint while in 'World' kinematics axis X is a virtual linear axis. This usually means that the same value will be too fast for Joint kinematics and too slow in World kinematics.

It probably makes sense to switch Velocity/Acceleration settings when switching kinematics.

The setup is the same as for switching limits which I have done in the demo config in this post:

forum.linuxcnc.org/39-pncconf/52783-soft-limit-setup#301669

The problem here is that in 'Joint' kinematics axis X is a rotational joint while in 'World' kinematics axis X is a virtual linear axis. This usually means that the same value will be too fast for Joint kinematics and too slow in World kinematics.

It probably makes sense to switch Velocity/Acceleration settings when switching kinematics.

The setup is the same as for switching limits which I have done in the demo config in this post:

forum.linuxcnc.org/39-pncconf/52783-soft-limit-setup#301669

Last edit: 15 Jun 2024 14:08 by Aciera. Reason: Forgot the link

Please Log in or Create an account to join the conversation.

Time to create page: 0.997 seconds