Trajectory Planner using Ruckig Lib

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

09 Nov 2023 21:26 #284974

by Grotius

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

09 Nov 2023 21:27 #284975

by Joco

Replied by Joco on topic Trajectory Planner using Ruckig Lib

Ahhh ! Cool - thanks. Wont chase ghosts then.

Re debian 12 - I did that ok yesterday. What is the issue/error?

Re debian 12 - I did that ok yesterday. What is the issue/error?

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

09 Nov 2023 22:36 #284986

by Joco

Replied by Joco on topic Trajectory Planner using Ruckig Lib

Test run on physical machine using the attached plasma wrench.

I had a look at the g code test file taht you have been using. It wont "just run" on my physical machine as it has negative positions. Normally I would move the wcs to cope but I can't so it wont let me run. How was generated? If from DXF could I have that so I can regenerate a version with nothing flowing into the negatives? Or is it programatic and easy to regenerate a version that stays in bounds? My plasma has a work area of X=1200 and Y=600 (actually 1290x610 but for test purposes keeping it simple). So a larger "stress" version of the file I can run across the whole space might be of use?

Also on feed rates - would it be possible to have the feeds for X/Y and Z set via two vars at the top of the file? That makes it super easy to quickly adjust for different stress levels on the run. If I have the source dxf or the generative prog I am happy to do that tweak.

Cheers - J.

I had a look at the g code test file taht you have been using. It wont "just run" on my physical machine as it has negative positions. Normally I would move the wcs to cope but I can't so it wont let me run. How was generated? If from DXF could I have that so I can regenerate a version with nothing flowing into the negatives? Or is it programatic and easy to regenerate a version that stays in bounds? My plasma has a work area of X=1200 and Y=600 (actually 1290x610 but for test purposes keeping it simple). So a larger "stress" version of the file I can run across the whole space might be of use?

Also on feed rates - would it be possible to have the feeds for X/Y and Z set via two vars at the top of the file? That makes it super easy to quickly adjust for different stress levels on the run. If I have the source dxf or the generative prog I am happy to do that tweak.

Cheers - J.

Attachments:

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

09 Nov 2023 23:28 #284992

by Joco

Cheers - J.

Replied by Joco on topic Trajectory Planner using Ruckig Lib

This might well have been solved. But he issue happened immediately after the completion of the first G0 in the wrench test file in my last post. It did a rapid to the Hole locaiton in the file then stalled.@Joco,

When the isnan occured, i suspect you did a mdi move for a given arc?

Do you remember the given gcode that caused the isnan? Thanks.

Cheers - J.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11696

- Thank you received: 3947

10 Nov 2023 00:24 #284993

by rodw

Replied by rodw on topic Trajectory Planner using Ruckig Lib

Must be. Its listed in your error file you attached here.

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

10 Nov 2023 02:23 #284997

by Joco

Replied by Joco on topic Trajectory Planner using Ruckig Lib

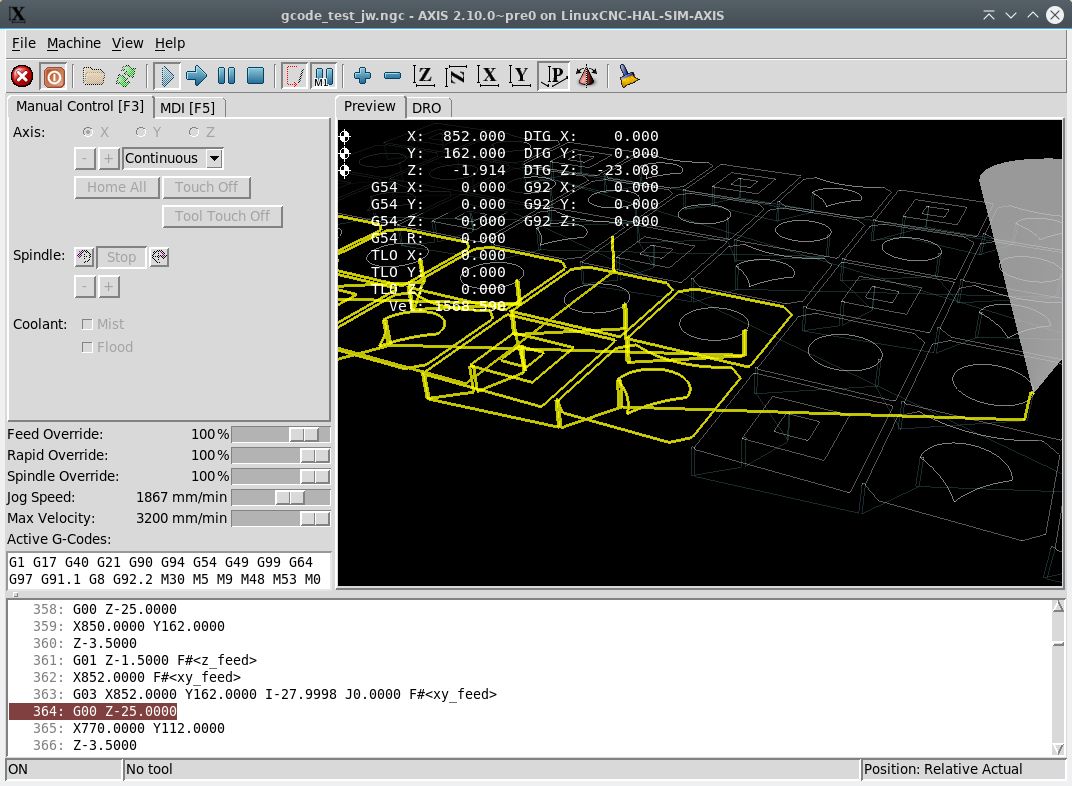

More testing. I managed to come up with a way to get the standard gcode file @Grotius was using and it into a dxf that I could manipulate in sheetcam to fill out a larger area. Then generate back into gcode.

Test file in use:

I have run this file under standard tp in 2.9 and 2.10pre. Works fine.

Under scurve it throws an error pretty much immediately. Attached log has all the deails.

But here is the snippet for the relvant issue (I believe):

Cheers - J.

Test file in use:

I have run this file under standard tp in 2.9 and 2.10pre. Works fine.

Under scurve it throws an error pretty much immediately. Attached log has all the deails.

But here is the snippet for the relvant issue (I believe):

tpSetVlimit. to: 333.316667

line startpoint x: 625.000000, y: 300.000000, z: -25.000000

line endpoint x: 625.000000, y: 300.000000, z: -25.000000

line startpoint x: 190.000000, y: 162.000000, z: -25.000000

line endpoint x: 190.000000, y: 162.000000, z: -25.000000

line startpoint USRMOT: ERROR: invalid command

can't add circular move at line 21, error code -1

waiting for s.joints<0>, s.kinematics_type<0>Cheers - J.

Attachments:

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

10 Nov 2023 05:51 #285001

by Grotius

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Hi Joco,

Thanks for your detailled error report.

The gcode file is from cam repository : github.com/grotius-cnc/cam/blob/main/gcode.ngc

I added your modified gcode_test_jw.ngc to the source. And opened the file in axis. Then press run after home,

and error reproduced indeed.

tpAddCircle.

vector size: 6

lengt of this segment: -nan

traject lenght now: -nan

arc startpoint x: 192.000000, y: 162.000000, z: -1.500000

arc endpoint x: 192.000000, y: 162.000000, z: -1.500000

arc center x: 164.000200, y: 162.000000, z: -1.500000

It's obvious, the arc has the same start- & endpoint, wich results in a isnan output for arc lenght in this case.

So i can do 2 things here.

Thanks for your detailled error report.

The gcode file is from cam repository : github.com/grotius-cnc/cam/blob/main/gcode.ngc

I added your modified gcode_test_jw.ngc to the source. And opened the file in axis. Then press run after home,

and error reproduced indeed.

tpAddCircle.

vector size: 6

lengt of this segment: -nan

traject lenght now: -nan

arc startpoint x: 192.000000, y: 162.000000, z: -1.500000

arc endpoint x: 192.000000, y: 162.000000, z: -1.500000

arc center x: 164.000200, y: 162.000000, z: -1.500000

It's obvious, the arc has the same start- & endpoint, wich results in a isnan output for arc lenght in this case.

So i can do 2 things here.

- Change it into a line when start & end are the same.

- Filter out this segment, trow it away

The following user(s) said Thank You: akb1212

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

10 Nov 2023 06:16 #285002

by Joco

Replied by Joco on topic Trajectory Planner using Ruckig Lib

So line 21 is: G03 X192.0000 Y162.0000 I-27.9998 J0.0000 F#<xy_feed>

This essentially a circle. Use ncviewer.com/ to step through the code file. Really useful to visualise what is happening where.

Are you factoring the fact the fact that the arc at this line is in fact a circle or is something happening under the hood which is causing this to happen as a result of what is being produced by the ruckig library?

Cheers - J

This essentially a circle. Use ncviewer.com/ to step through the code file. Really useful to visualise what is happening where.

Are you factoring the fact the fact that the arc at this line is in fact a circle or is something happening under the hood which is causing this to happen as a result of what is being produced by the ruckig library?

Cheers - J

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

10 Nov 2023 06:23 #285003

by Grotius

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

The isnan is fixed by changing isnan to 0 output. So segment's are just there, segment lenght is set to zero.

To inform you where in the source this is done :

github.com/grotius-cnc/linuxcnc/blob/884.../tp/tp_lines.cpp#L89

github.com/grotius-cnc/linuxcnc/blob/884.../tp/tp_arcs.cpp#L233

Github is updated.

Joco, it seems the rapids are below the workpiece. But the file run's oke now.

You may edit the file yourself on github.

To inform you where in the source this is done :

github.com/grotius-cnc/linuxcnc/blob/884.../tp/tp_lines.cpp#L89

github.com/grotius-cnc/linuxcnc/blob/884.../tp/tp_arcs.cpp#L233

Github is updated.

Joco, it seems the rapids are below the workpiece. But the file run's oke now.

You may edit the file yourself on github.

Attachments:

The following user(s) said Thank You: akb1212

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

10 Nov 2023 06:27 - 10 Nov 2023 06:35 #285004

by Joco

Replied by Joco on topic Trajectory Planner using Ruckig Lib

Thanks - yeah its a hack as I can't set WCS to be able to have positive upward Z moves.

Normally Z would be removed on my plasma as that is all under plasmac control. Once WCS can be set then will change. OR is it ok to kill off Z moves entirley? For the purposes of this test file.

J.

Normally Z would be removed on my plasma as that is all under plasmac control. Once WCS can be set then will change. OR is it ok to kill off Z moves entirley? For the purposes of this test file.

J.

Last edit: 10 Nov 2023 06:35 by Joco.

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

Time to create page: 0.201 seconds