- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

18 Aug 2017 17:35 - 18 Aug 2017 17:43 #97718

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Last edit: 18 Aug 2017 17:43 by tecno.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17515

- Thank you received: 5120

19 Aug 2017 03:21 #97729

by PCW

Replied by PCW on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Are you sure its bad? how have you tested it?

Index is quite short on high resolution encoders so its hard to catch

without using the encoder counter hardware

Index is quite short on high resolution encoders so its hard to catch

without using the encoder counter hardware

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2017 06:01 #97731

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Hal show

Turning spindle by hand very very slowly where I can clearly see A/B transitions but nothing on Index.

What is the best way to check spindle Index function within LCNC? Any examples to try?

Turning spindle by hand very very slowly where I can clearly see A/B transitions but nothing on Index.

What is the best way to check spindle Index function within LCNC? Any examples to try?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2017 10:02 #97732

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Question

I have a manual switch on my frontpanel and want to be able to run flood coolant manually.

Following in my hal file

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# --- DIN-01 Coolant pump ---

net din-01 <= hm2_7i76e.0.7i73.0.1.input-20

# --- COOLANT-FLOOD ---

net coolant-flood hm2_7i76e.0.7i76.0.0.output-04

net din-01 hm2_7i76e.0.7i76.0.0.output-04

Is this the correct way to net functions wanted?

I have a manual switch on my frontpanel and want to be able to run flood coolant manually.

Following in my hal file

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# --- DIN-01 Coolant pump ---

net din-01 <= hm2_7i76e.0.7i73.0.1.input-20

# --- COOLANT-FLOOD ---

net coolant-flood hm2_7i76e.0.7i76.0.0.output-04

net din-01 hm2_7i76e.0.7i76.0.0.output-04

Is this the correct way to net functions wanted?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

19 Aug 2017 11:05 #97735

by andypugh

The definitive way would be to "sets xxx-index-enable true" then rotate the spindle and see if it ever goes false.

The software needs to see index-enable go false to start the tapping cycle, but I don't know if it technically requires that it be in the right place unless you are doing rigid tapping.

You could try an experiment where you start a rigid tapping move (MDI) then manually "sets xxx-index-enable false" when you see it get set to true. It will either work or give a following error, I don't know which. If it gives a following-error then it means that it also requires the counts to be zeroed (another effect of index-enable)

I can imagine generating an index pulse in HAL and sending that to the encoder counter working (just as long as you don't peck-tap)

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Hal show

Turning spindle by hand very very slowly where I can clearly see A/B transitions but nothing on Index.

The definitive way would be to "sets xxx-index-enable true" then rotate the spindle and see if it ever goes false.

The software needs to see index-enable go false to start the tapping cycle, but I don't know if it technically requires that it be in the right place unless you are doing rigid tapping.

You could try an experiment where you start a rigid tapping move (MDI) then manually "sets xxx-index-enable false" when you see it get set to true. It will either work or give a following error, I don't know which. If it gives a following-error then it means that it also requires the counts to be zeroed (another effect of index-enable)

I can imagine generating an index pulse in HAL and sending that to the encoder counter working (just as long as you don't peck-tap)

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2017 11:24 #97738

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

The definitive way would be to "sets xxx-index-enable true" then rotate the spindle and see if it ever goes false.

Will try this and see what is going on.

Thanks

Will try this and see what is going on.

Thanks

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2017 12:03 #97740

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Sorry No Go so the index pulse is broken.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2017 12:17 - 19 Aug 2017 13:45 #97741

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

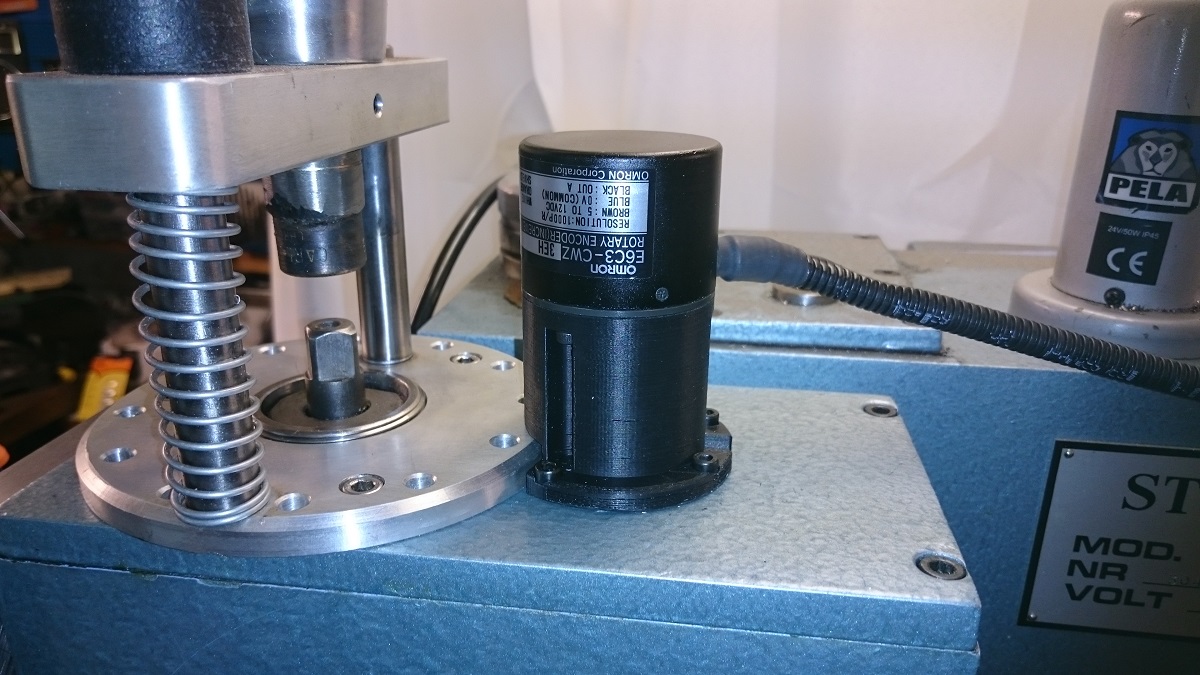

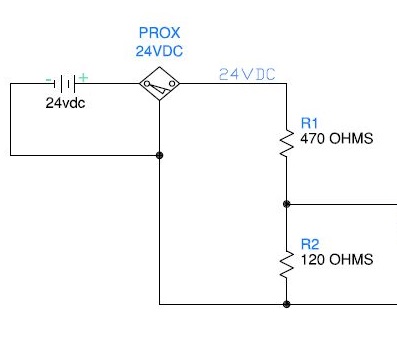

So I will have to go with inductive sensor but all I have are suited for 24VDC.

How can I safely connect these 3-wire sensors like this one www.ifm.com/products/ind/ds/IE5288.htm

Assuming a serial resistor on pin 4 to pin 13 on TB3?

Is this OK with a divider?

Found another better one that can do 3kHz = PNP NO

Done some testing supplying 4.9VDC and I get out 4.3VDC, any chance this can be reliable up to 3kHz?

Specs say to supply 10-30VDC

How can I safely connect these 3-wire sensors like this one www.ifm.com/products/ind/ds/IE5288.htm

Assuming a serial resistor on pin 4 to pin 13 on TB3?

Is this OK with a divider?

Found another better one that can do 3kHz = PNP NO

Done some testing supplying 4.9VDC and I get out 4.3VDC, any chance this can be reliable up to 3kHz?

Specs say to supply 10-30VDC

Last edit: 19 Aug 2017 13:45 by tecno. Reason: Added picture - added text

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

20 Aug 2017 08:15 #97762

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

If you use NPN proximity switches you can connect them directly to 7i73 inputs as they act as a switch-to-ground.

I have 24V NPN proxes connected to the 7i73 in my Lathe apron.

(Don't try this with PNP though)

I have 24V NPN proxes connected to the 7i73 in my Lathe apron.

(Don't try this with PNP though)

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2017 08:17 #97763

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Spindle encoder on 7i76e with no Index pulse.

Have only PNP for max 3kHz in my bag of tricks

Have only PNP for max 3kHz in my bag of tricks

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.144 seconds