- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

01 Aug 2017 10:18 #96820

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Yesterday shows a spindle speed command of 101 and a spinout of 101. And a matching voltage.

Today shows a spindle speed command of 1400 but does not show the spinout number. We need to know if that is 101 or 1400 to know where the problem lies.

It could well be due to the minlim and maxlim parameters. Which is why I asked about them.

Today shows a spindle speed command of 1400 but does not show the spinout number. We need to know if that is 101 or 1400 to know where the problem lies.

It could well be due to the minlim and maxlim parameters. Which is why I asked about them.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

01 Aug 2017 10:19 #96821

by andypugh

I am trying to help other people too. I lose track of who has what hardware. Sorry.

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

No 5i25 !! 7i76E

I am trying to help other people too. I lose track of who has what hardware. Sorry.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

01 Aug 2017 10:22 #96822

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

It could well be due to the minlim and maxlim parameters

Where are these parameters?

Where are these parameters?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

01 Aug 2017 10:45 #96823

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Look in the "parameters" section of "Show HAL config"

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

01 Aug 2017 10:51 #96824

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

spinout minlim 0

spinout maxlim 100

spinout scale 2000

spinout maxlim 100

spinout scale 2000

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

01 Aug 2017 10:56 #96825

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Well, there you are then! That is why you only get 100 rpm output.

You need ain the HAL file in the same place as where you set the scale.

You need a

setp ....spinout-maxlim 2000

The following user(s) said Thank You: tecno

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

01 Aug 2017 11:09 #96827

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Thank you very much Andy one very happy camper here now.

Your help is very much appreciated.

Your help is very much appreciated.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

01 Aug 2017 11:54 - 01 Aug 2017 11:54 #96829

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I have now made course adjustment of scale to 1200 so true rpm is very close.

Giving M3 S50 gives 46rpm.

Question, spindle encoder is showing approx 3000/3200 for velocity, where do I scale this?

Giving M3 S50 gives 46rpm.

Question, spindle encoder is showing approx 3000/3200 for velocity, where do I scale this?

Last edit: 01 Aug 2017 11:54 by tecno.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19762

- Thank you received: 4589

01 Aug 2017 12:23 #96831

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

There should be an encoder scale parameter (look in HAL config for the exact name) and you can "setp" this to the correct counts-per-rev.

If you are planning to use the spindle for tapping etc then the scale needs to give 1 revolution output per actual revolution. However if you only want it to monitor spindle speed then you can multiply the scale by 60 to get an revs-per-minute rather than rev-per-second output in the velocity.

If you do want to use spindle-synched motion then the factor of 60 needs to be in a HAL "scale" component.

If you are planning to use the spindle for tapping etc then the scale needs to give 1 revolution output per actual revolution. However if you only want it to monitor spindle speed then you can multiply the scale by 60 to get an revs-per-minute rather than rev-per-second output in the velocity.

If you do want to use spindle-synched motion then the factor of 60 needs to be in a HAL "scale" component.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

01 Aug 2017 14:22 #96835

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Will put encoder aside a while as I just realized that Z puls is not working.

Back to the spindle as there are problems still or should I say need of improvements.

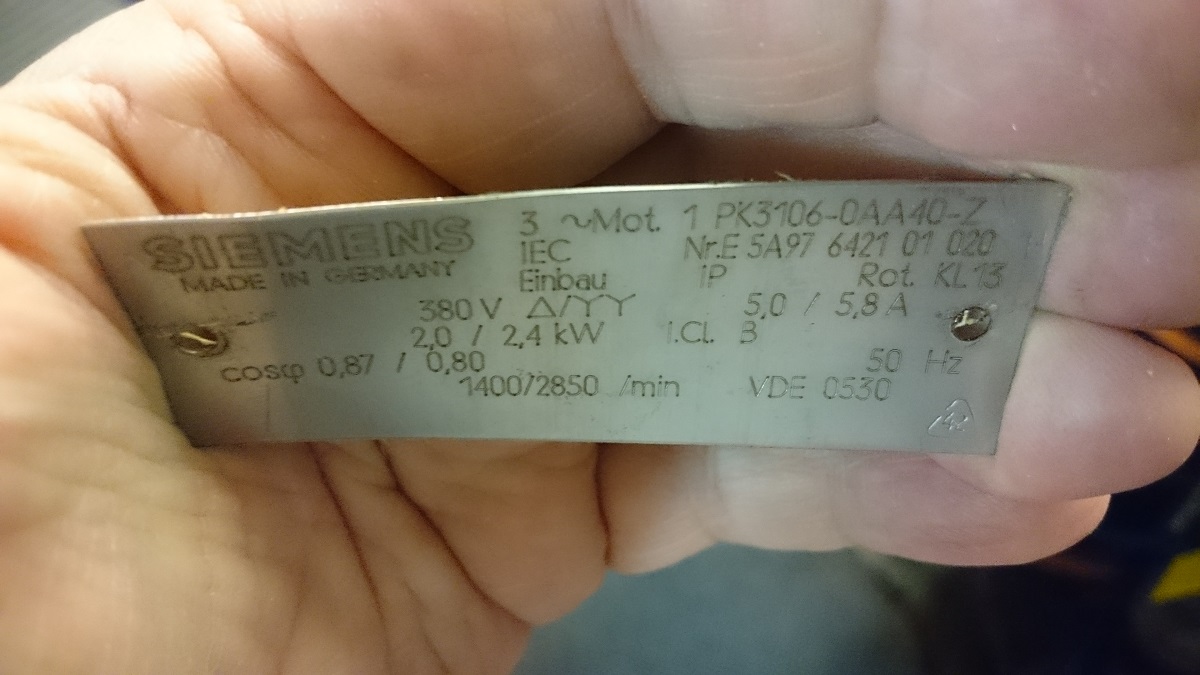

I have a 2-speed 3-phase motor with 1400/2850 rpm = Output 10 controls this.

As a first step I need to have monitoring of true rpm and make a switch to high rpm at say 800rpm.

How can this be done?

When I get the milling machine going I will make further improvement on controlling gearbox as I can not get good enough torque just by letting VFD go to lower revs so the gearbox is very well needed working with large milling cutters.

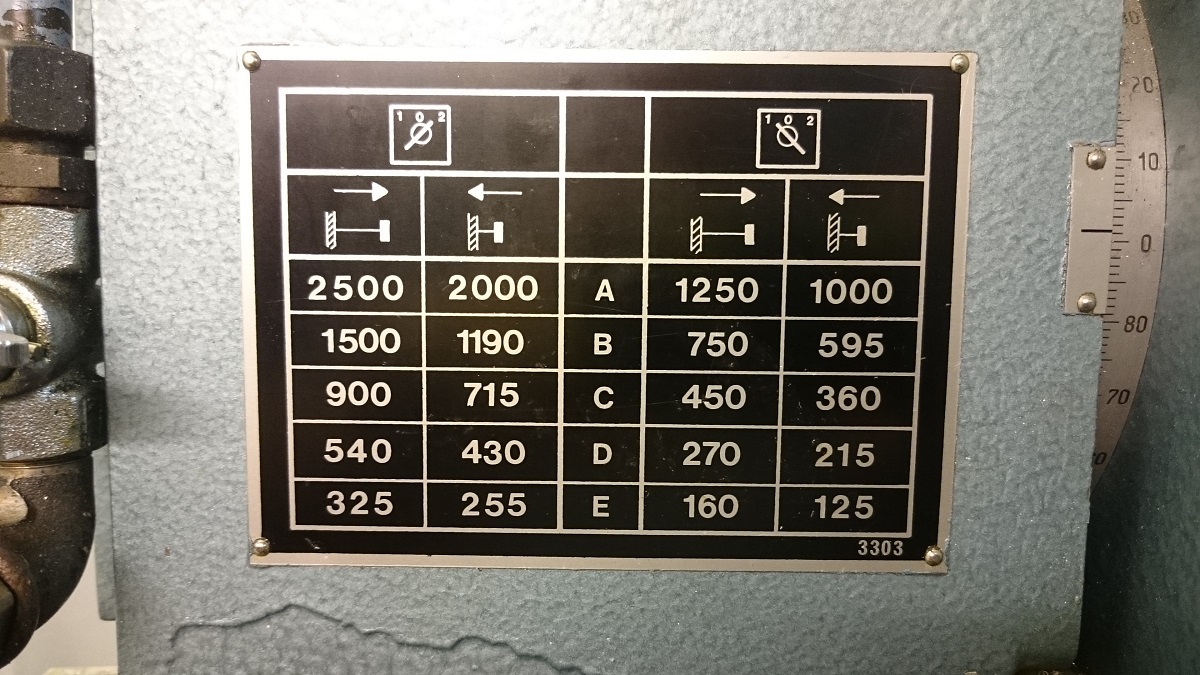

Looks like this

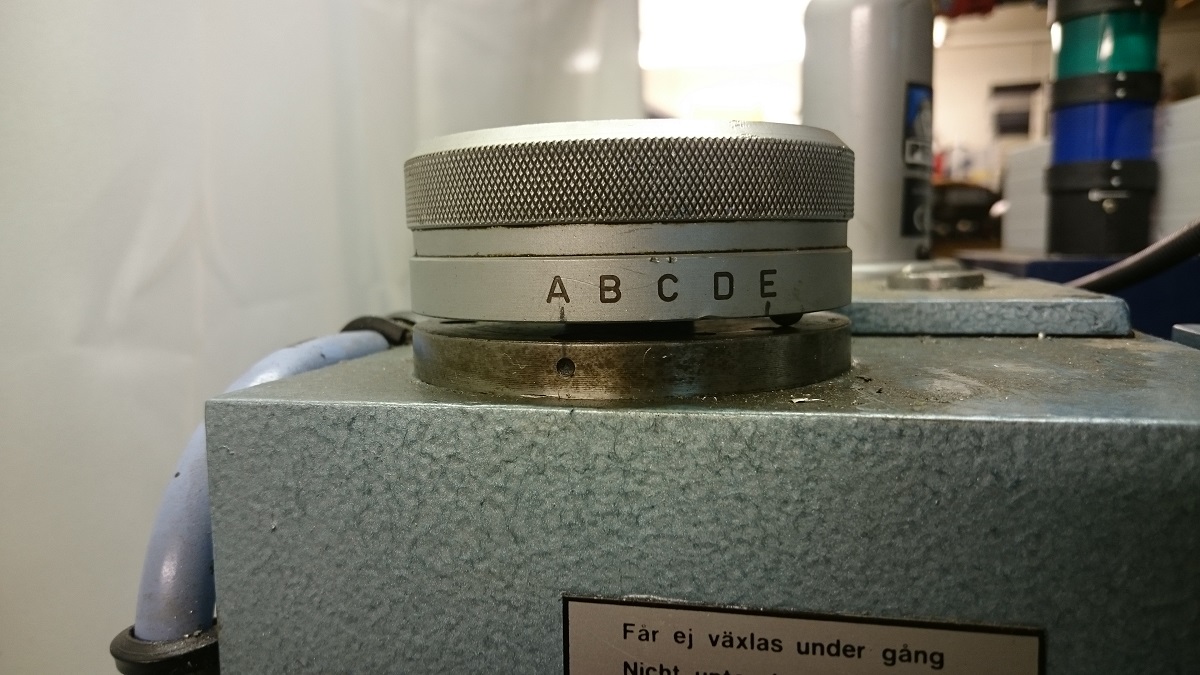

So I need to make a *reader* for the gearshift A-B-C-D-E as well as the Hi/Lo lever on the side.

All to be set manually but halting spindle for gear change to appropriate rpm.

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 1200

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

Above is obviously not correct as I can not get more than 1200rpm

Encoder is a must to monitor velocity but how to implement this so the speed shift can be accomplished?

This setup was working in my previous life with other system.

Any help to get me in the right direction is most welcome.

Cheers

Bengt

Back to the spindle as there are problems still or should I say need of improvements.

I have a 2-speed 3-phase motor with 1400/2850 rpm = Output 10 controls this.

As a first step I need to have monitoring of true rpm and make a switch to high rpm at say 800rpm.

How can this be done?

When I get the milling machine going I will make further improvement on controlling gearbox as I can not get good enough torque just by letting VFD go to lower revs so the gearbox is very well needed working with large milling cutters.

Looks like this

So I need to make a *reader* for the gearshift A-B-C-D-E as well as the Hi/Lo lever on the side.

All to be set manually but halting spindle for gear change to appropriate rpm.

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 1200

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

Above is obviously not correct as I can not get more than 1200rpm

Encoder is a must to monitor velocity but how to implement this so the speed shift can be accomplished?

This setup was working in my previous life with other system.

Any help to get me in the right direction is most welcome.

Cheers

Bengt

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.161 seconds