- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1148

- Thank you received: 409

09 Sep 2018 18:40 - 09 Sep 2018 18:42 #117247

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

No keep it as it is, as least for now.

I think the speeds and required gears are not reflecting your gearbox.

You need to double check that.In the reqd_gear array you need to enter the number that correspond to the gear lever settings.

How that number is calculated you can see in the line "actual = (gear_high * 0x40 and so on"

For the first gear you need low_speed and motor_low and gear_E engaged. That gives 0x01 (gear_E * 0x01).

For the second gear, which obviously is wrong then, but just assume you need gear_high, motor low and gear_D. That gives the number 0x42 (gear_high * 0x40 + gear_D * 0x02). That should go in as third number in reqd_gear instead of 0x21. BUt you must use the actual gear lever settings for the second gear, not this made up example.

You need to go through your gearbox for all the gears and make sure you have the right numbers entered,

I think the speeds and required gears are not reflecting your gearbox.

You need to double check that.

// These need to be edited to suit the gearbox

int speeds[15] = {0, 80, 125, 160, 215, 270, 360, 450, 595, 750, 1000, 1191, 1500, 2500, 0x1P30};

int reqd_gear[15] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x48, 0x68, 0x50, 0x70, 0x0};

if (spindle_speed_in == 0) return;

actual = (gear_high * 0x40 + motor_high * 0x20 + gear_A * 0x10 + gear_B * 0x08 + gear_C * 0x04 + gear_D * 0x02 + gear_E * 0x01);

for (i = 0; spindle_speed_in > speeds[i] && i < 14; i++);

gear_required = reqd_gear[i];

if (gear_required == actual && gear_required != 0x0){ // We are in the right gearHow that number is calculated you can see in the line "actual = (gear_high * 0x40 and so on"

For the first gear you need low_speed and motor_low and gear_E engaged. That gives 0x01 (gear_E * 0x01).

For the second gear, which obviously is wrong then, but just assume you need gear_high, motor low and gear_D. That gives the number 0x42 (gear_high * 0x40 + gear_D * 0x02). That should go in as third number in reqd_gear instead of 0x21. BUt you must use the actual gear lever settings for the second gear, not this made up example.

You need to go through your gearbox for all the gears and make sure you have the right numbers entered,

Last edit: 09 Sep 2018 18:42 by Hakan.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 18:46 #117248

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I see the problem with 0-80rpm that does not exist as gear1 is 80-125.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1148

- Thank you received: 409

09 Sep 2018 19:26 - 09 Sep 2018 19:27 #117251

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

That is not the problem now. First gear worked, so the logic works.

But I can see that Andy put in for the second gear 125-160 0x21.

That means motor_high and gear_E. Is that correct?

I understand it was another combination for the 125-160 gear, or?

Leave the 0-80 for now.

Regarding the delay, perhaps you should build some logic with buttons using the motor_enable signal?

But I can see that Andy put in for the second gear 125-160 0x21.

That means motor_high and gear_E. Is that correct?

I understand it was another combination for the 125-160 gear, or?

Leave the 0-80 for now.

Regarding the delay, perhaps you should build some logic with buttons using the motor_enable signal?

Last edit: 09 Sep 2018 19:27 by Hakan.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 19:32 #117252

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

forum.linuxcnc.org/39-pncconf/33069-help...ing?start=590#116905

My table is correct, will have to verify tomorrow as I just now only have my small laptop at hand.

My table is correct, will have to verify tomorrow as I just now only have my small laptop at hand.

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1148

- Thank you received: 409

09 Sep 2018 19:55 #117253

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Yes you are right, the table looks ok, although I just checked the two first gears

The message you get, can that be that the message is "off by one" gear?

If so you can change the numbering either in hal or in the comp, but maybe try in the hal file?

The message you get, can that be that the message is "off by one" gear?

If so you can change the numbering either in hal or in the comp, but maybe try in the hal file?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 20:02 #117256

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Always better with another pair of eyes, suspected 1step off.

Will dive into this tomorrow, thanks for the help Håkan always appreciated.

Assuming you are following the election as everybody else in Sweden.

Will dive into this tomorrow, thanks for the help Håkan always appreciated.

Assuming you are following the election as everybody else in Sweden.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 20:11 #117257

by tecno

Can you see anything why High-Gear is not working = nothing to VFD.

Maybe the comp is needed to be changed and not hal.

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Yes you are right, the table looks ok, although I just checked the two first gears

The message you get, can that be that the message is "off by one" gear?

If so you can change the numbering either in hal or in the comp, but maybe try in the hal file?

Can you see anything why High-Gear is not working = nothing to VFD.

Maybe the comp is needed to be changed and not hal.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

10 Sep 2018 08:45 #117284

by tecno

OK, I think I have found the error

actual = (gear_high * 0x40 + motor_high * 0x20

these two are flipped and should be motor_high * 0x40 + gear_high * 0x20

Look in table here forum.linuxcnc.org/39-pncconf/33069-help...ing?start=590#116905

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Always better with another pair of eyes, suspected 1step off.

Will dive into this tomorrow, thanks for the help Håkan always appreciated.

Assuming you are following the election as everybody else in Sweden.

OK, I think I have found the error

actual = (gear_high * 0x40 + motor_high * 0x20

these two are flipped and should be motor_high * 0x40 + gear_high * 0x20

Look in table here forum.linuxcnc.org/39-pncconf/33069-help...ing?start=590#116905

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

10 Sep 2018 13:47 #117289

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Edited comp file

int speeds[15] = {0, 125, 160,

Deleted 80 so now first gear goes from 0 to 125 (I can live with that )

)

All gears work up to 1000rpm (not running at correct speeds that I have to tune) with gear settings.

But all gears over 1000rpm involve motor to be set at high speed does not work.

int speeds[15] = {0, 125, 160,

Deleted 80 so now first gear goes from 0 to 125 (I can live with that

All gears work up to 1000rpm (not running at correct speeds that I have to tune) with gear settings.

But all gears over 1000rpm involve motor to be set at high speed does not work.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

10 Sep 2018 16:00 #117294

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

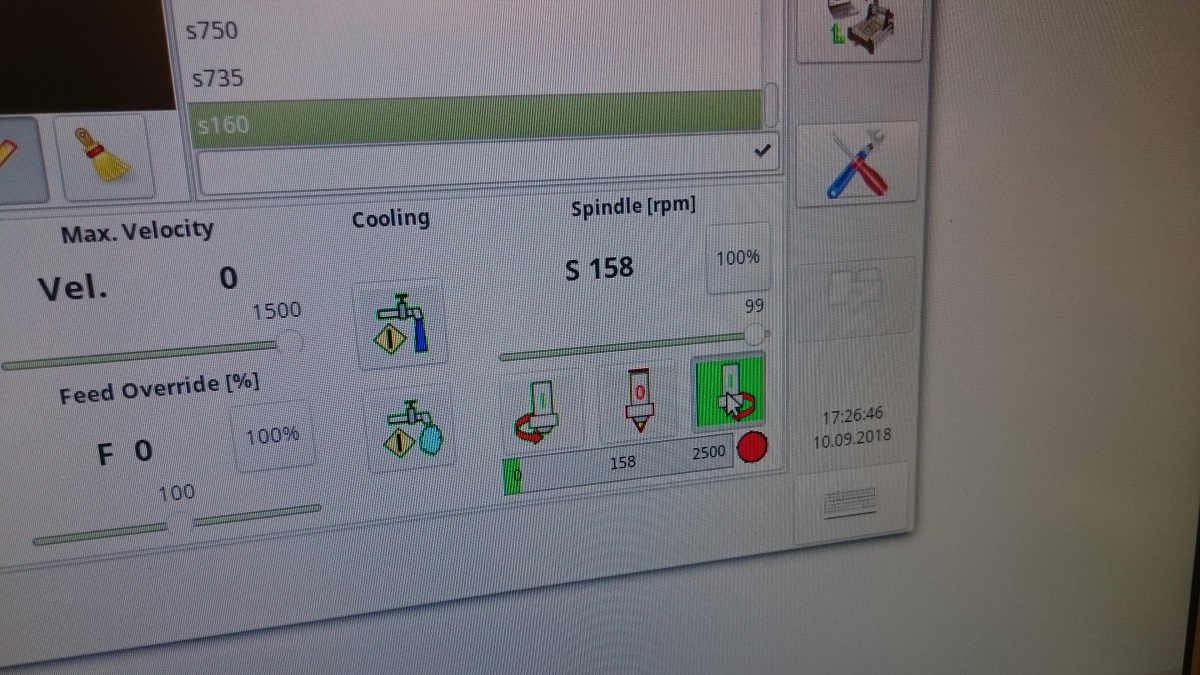

It looks like this with not correct spindle rpm. S160 shows up in gmoccapy as 158 and in reality 74.2rpm

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.281 seconds