- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

07 Sep 2018 17:37 - 07 Sep 2018 17:54 #117198

by tecno

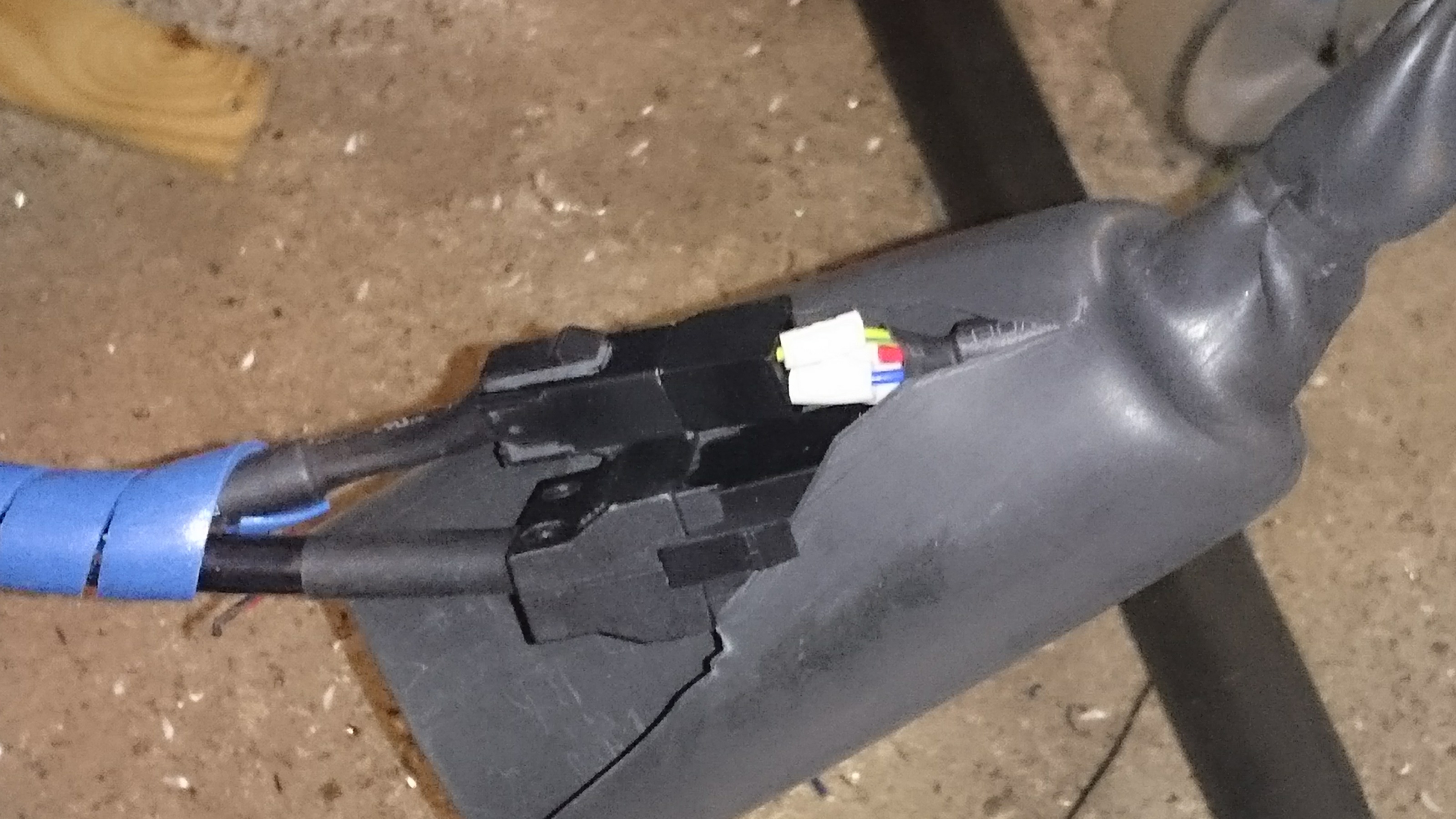

I found the error = SHIT CONNECTORS!!!!!!

From motor there is a fixed cable and ends in 4-pole connector = bad hooks !! So now I have to do something that fixes this this connection SOLID!

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

As a side note, homed all my axis and suddenly X is out of order.

Power on but not stiff as I can rotate shaft by hand = no error message on driver.

I found the error = SHIT CONNECTORS!!!!!!

From motor there is a fixed cable and ends in 4-pole connector = bad hooks !! So now I have to do something that fixes this this connection SOLID!

Last edit: 07 Sep 2018 17:54 by tecno. Reason: added jpg

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1067

- Thank you received: 359

07 Sep 2018 17:40 #117199

by Hakan

This is not what I call code. These are hal connections.

There is no code in the comp to use anything but 2500 rpm as the max speed.

Add the four lines. Or Andy maybe has an other idea how to do it.

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I know, but there is no code to set different max speeds when the pin is high or low.

I added that code.

# Motor High

net motor-high-signal <= GB-2speed.0.motor-high

net motor-high-signal => hm2_7i76e.0.7i76.0.0.output-10

Gear setting 10-11-12-13 should activate above as I understood this.

This is not what I call code. These are hal connections.

There is no code in the comp to use anything but 2500 rpm as the max speed.

Add the four lines. Or Andy maybe has an other idea how to do it.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

07 Sep 2018 17:43 - 07 Sep 2018 18:01 #117201

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Will the 4 lines handle output 10 when needed?

FUNCTION(_){

int actual, message, double motor_max_speed;

int i;

// These need to be edited to suit the gearbox

int speeds[15] = {0, 80, 125, 160, 215, 270, 360, 450, 595, 750, 1000, 1191, 1500, 2500, 0x1P30};

int reqd_gear[15] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x48, 0x68, 0x50, 0x70, 0x0};

if (spindle_speed_in == 0) return;

actual = (gear_high * 0x40 + motor_high * 0x20 + gear_A * 0x10 + gear_B * 0x08 + gear_C * 0x04 + gear_D * 0x02 + gear_E * 0x01);

for (i = 0; spindle_speed_in > speeds[i] && i < 14; i++);

gear_required = reqd_gear[i];

if (gear_required == actual && gear_required != 0x0){ // We are in the right gear

spindle_enable_out = spindle_enable_in;

if (motor_high)

motor_max_speed = 2500;

else

motor_max_speed = 1450;

motor_speed_out = speeds[13] * (spindle_speed_in / speeds[i+1]);

Last edit: 07 Sep 2018 18:01 by tecno. Reason: added text

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1067

- Thank you received: 359

08 Sep 2018 07:40 #117212

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Almost, the "speed[13]" on the last line needs to be replaced as well.

Check forum.linuxcnc.org/39-pncconf/33069-help...ing?start=640#117193

If you have a different max speed than 1450 you can just change to whatever is the max speed.

Check forum.linuxcnc.org/39-pncconf/33069-help...ing?start=640#117193

If you have a different max speed than 1450 you can just change to whatever is the max speed.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Sep 2018 09:09 #117214

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Compiles but will not install

bengt@CombiMll ~/linuxcnc/configs/GB_2speed $ sudo halcompile --install GB_2speed.comp

Compiling realtime GB_2speed.c

GB_2speed.comp: In function ‘_’:

GB_2speed.comp:25:23: error: expected identifier or ‘(’ before ‘double’

GB_2speed.comp:38:20: error: ‘motor_max_speed’ undeclared (first use in this function)

GB_2speed.comp:38:20: note: each undeclared identifier is reported only once for each function it appears in

/usr/share/linuxcnc/Makefile.modinc:113: receptet för målet ”GB_2speed.o” misslyckades

make: *** [GB_2speed.o] Fel 1Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Sep 2018 10:05 #117216

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

FUNCTION(_){

int actual, message, motor_max_speed;

deleted word double and now it installs.

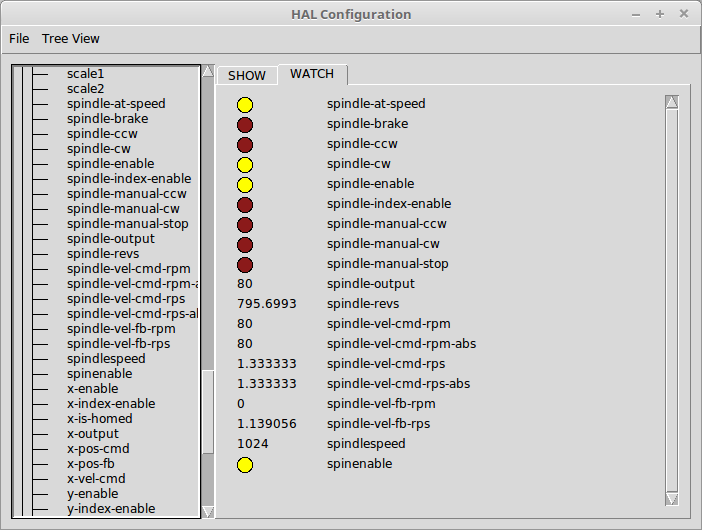

S80 now spinning at 63rpm

int actual, message, motor_max_speed;

deleted word double and now it installs.

S80 now spinning at 63rpm

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Sep 2018 10:36 - 08 Sep 2018 11:38 #117217

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Last edit: 08 Sep 2018 11:38 by tecno. Reason: added text

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 Sep 2018 11:52 #117219

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I noticed one thing that must be addressed and that is to implement a delay before spindle to start.

If I command S80 and have the correct gear the spindle starts = OK

If I have wrong gear I get prompted to change gear but as soon as I get that gear close or near it starts to spin with the risk of damaging gears within the gearbox. It is in this situation a delay is a must.

How can this be done?

If I command S80 and have the correct gear the spindle starts = OK

If I have wrong gear I get prompted to change gear but as soon as I get that gear close or near it starts to spin with the risk of damaging gears within the gearbox. It is in this situation a delay is a must.

How can this be done?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 15:32 #117240

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

09 Sep 2018 16:54 #117243

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Maybe this is the right medicine to get gear ranges in place?

// These need to be edited to suit the gearbox

int speeds[13] = {80, 125, 160, 215, 270, 360, 450, 595, 750, 1000, 1190, 1500, 2500};

int reqd_gear[13] = {0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x48, 0x68, 0x50, 0x70};

for (i = 0; spindle_speed_in > speeds && i < 12; i++);

// These need to be edited to suit the gearbox

int speeds[13] = {80, 125, 160, 215, 270, 360, 450, 595, 750, 1000, 1190, 1500, 2500};

int reqd_gear[13] = {0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x48, 0x68, 0x50, 0x70};

for (i = 0; spindle_speed_in > speeds && i < 12; i++);

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.240 seconds