- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

15 Sep 2018 12:23 #117573

by tecno

Made some changes but still not OK

I can get E and E+HG, D and A to run but with wrong rpm.

E S100 goes to overload and runs at 1.84Hz

S80 runs at 40.8Hz = 278 rpm

E+HG S200 goes to overload and 1.84Hz

S160 runs at 40.8Hz 221 rpm

S101 runs at 25.36Hz 137.2 rpm

D S350 1.74Hz

S280 runs at 40.8Hz 463 rpm

S201 runs at 28.9Hz 328 rpm

D+HG C and C+HG B and B+HG and A+HG are not working

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

MAX_OUTPUT = 2500.0 in INI

Max on each gearsetting the motor should run at 50Hz or there about and be adjusted down to each gears minimum from VFD.

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Made some changes but still not OK

I can get E and E+HG, D and A to run but with wrong rpm.

E S100 goes to overload and runs at 1.84Hz

S80 runs at 40.8Hz = 278 rpm

E+HG S200 goes to overload and 1.84Hz

S160 runs at 40.8Hz 221 rpm

S101 runs at 25.36Hz 137.2 rpm

D S350 1.74Hz

S280 runs at 40.8Hz 463 rpm

S201 runs at 28.9Hz 328 rpm

D+HG C and C+HG B and B+HG and A+HG are not working

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

MAX_OUTPUT = 2500.0 in INI

Max on each gearsetting the motor should run at 50Hz or there about and be adjusted down to each gears minimum from VFD.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

15 Sep 2018 13:31 #117574

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

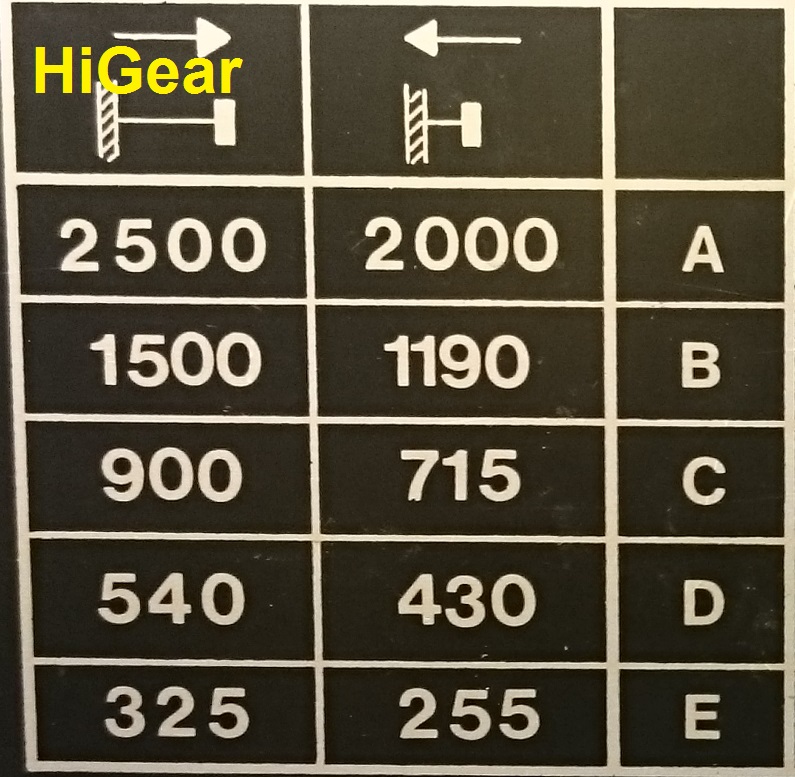

I have just edited the comp with new ranges as per the enclosed picture = original gearbox speed and see what the actual result will be.

I´ll be back soon.

I´ll be back soon.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

15 Sep 2018 14:46 - 15 Sep 2018 14:48 #117576

by tecno

Here my findings

To get E in low gear to run as it should I had to edit setp hm2_7i76e.0.7i76.0.0.spinout-scalemax to 3255 (2400)

E S255 runs at 255.1 / 37.5Hz

E HighGear S325 runs at 202.9 / 37.4Hz !!! WTF !!!

D S430 runs at 425.5 / 37.4Hz

-

-

-

-

-

A S2000 runs at 1956 / 37.4Hz

-

.

All other gears nothing !

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I have just edited the comp with new ranges as per the enclosed picture = original gearbox speed and see what the actual result will be.

I´ll be back soon.

Here my findings

To get E in low gear to run as it should I had to edit setp hm2_7i76e.0.7i76.0.0.spinout-scalemax to 3255 (2400)

E S255 runs at 255.1 / 37.5Hz

E HighGear S325 runs at 202.9 / 37.4Hz !!! WTF !!!

D S430 runs at 425.5 / 37.4Hz

-

-

-

-

-

A S2000 runs at 1956 / 37.4Hz

-

.

All other gears nothing !

Last edit: 15 Sep 2018 14:48 by tecno.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

15 Sep 2018 17:54 #117582

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I found a bloody mess in hexadecimal numbers, will go down and test now.

faulty line int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x04, 0x36, 0x08, 0x40, 0x16, 0x10, 0x48, 0x0};

Corrected int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x48, 0x28, 0x10, 0x30, 0x0};

faulty line int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x04, 0x36, 0x08, 0x40, 0x16, 0x10, 0x48, 0x0};

Corrected int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x48, 0x28, 0x10, 0x30, 0x0};

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

15 Sep 2018 19:37 #117585

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

At last I am getting somewhere but not quite there.

1. I have never used the manual gearbox and obviously I have misread the gearbox label

HighGear must be set net high-gear-signal => GB-3speed.0.gear-high <= hm2_7i76e.0.7i76.0.0.input-14-not

2. scaling to be at setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2000

3. Gear speeds

E

S255 > 257 /47.3Hz

E+HG

S325 > 315 /46.2Hz

D

S430 > 429 /47.5Hz

D+HG

S540 > 525 /46.2Hz

C

S715 > 714 /47.4Hz

C+HG

S900 > 876 /46.3Hz

B

S1190 > NOTHING

B+HG

S1500 > 1444 /45.89Hz

A

S2000 > 1949 /47.45Hz

A+HG

S2500 > NOTHING

INI still max 2500 rpm

So where start to search for why B and A+HG does not work, any hints on where to look?

1. I have never used the manual gearbox and obviously I have misread the gearbox label

HighGear must be set net high-gear-signal => GB-3speed.0.gear-high <= hm2_7i76e.0.7i76.0.0.input-14-not

2. scaling to be at setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2000

3. Gear speeds

E

S255 > 257 /47.3Hz

E+HG

S325 > 315 /46.2Hz

D

S430 > 429 /47.5Hz

D+HG

S540 > 525 /46.2Hz

C

S715 > 714 /47.4Hz

C+HG

S900 > 876 /46.3Hz

B

S1190 > NOTHING

B+HG

S1500 > 1444 /45.89Hz

A

S2000 > 1949 /47.45Hz

A+HG

S2500 > NOTHING

INI still max 2500 rpm

So where start to search for why B and A+HG does not work, any hints on where to look?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

16 Sep 2018 07:10 #117594

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Found another slam creeper

B

S1190 > NOTHING (was 0x48)

int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x30, 0x0};

So A+HG is the last problem, assume that something is not set correctly in hal or ini

B

S1190 > NOTHING (was 0x48)

int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x30, 0x0};

So A+HG is the last problem, assume that something is not set correctly in hal or ini

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

16 Sep 2018 09:14 #117599

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Haha I am sure slam creeper does not translate into something understandable

Guess you need to work with halshow for all the pins to figure out the last one.

Guess you need to work with halshow for all the pins to figure out the last one.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

16 Sep 2018 09:35 #117600

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Good news is that the comp is working alright, tested to run VFD with fixed frequency and A+HG works also so all numbers are OK for gear settings.

So my conclusion is that there must be a parameter setting in the VFD that goes in overload or something like that when selecting A + HG 2001-2500 rpm.

www.vfds.com/manuals/mitsubishi/mitsubishi-a500-manual.pdf

Reading the manual is creepy for me = so many parameters and to see what is the ones to be adjusted.

So in short I´m a happy camper with the comp now. Small tweaks needs to be done.

So my conclusion is that there must be a parameter setting in the VFD that goes in overload or something like that when selecting A + HG 2001-2500 rpm.

www.vfds.com/manuals/mitsubishi/mitsubishi-a500-manual.pdf

Reading the manual is creepy for me = so many parameters and to see what is the ones to be adjusted.

So in short I´m a happy camper with the comp now. Small tweaks needs to be done.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

16 Sep 2018 10:10 - 16 Sep 2018 10:26 #117601

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Oops to fast to rule out the comp.

Gear required 48 is there but nothing on output so there must be something else wrong in comp.

Gear required 48 is there but nothing on output so there must be something else wrong in comp.

FUNCTION(_){

int actual, message, motor_max_speed;

int i;

// These need to be edited to suit the gearbox

int speeds[12] = {0, 255, 325, 430, 540, 715, 900, 1190, 1500, 2000, 2500, 0x1P30};

int reqd_gear[12] = {0x0, 0x01, 0x21, 0x02, 0x22, 0x04, 0x24, 0x08, 0x28, 0x10, 0x30, 0x0};

if (spindle_speed_in == 0) return;

actual = (gear_high * 0x20 + gear_A * 0x10 + gear_B * 0x08 + gear_C * 0x04 + gear_D * 0x02 + gear_E * 0x01);

for (i = 0; spindle_speed_in > speeds[i] && i < 10; i++);

gear_required = reqd_gear[i];

if (gear_required == actual && gear_required != 0x0){ // We are in the right gear

spindle_enable_out = spindle_enable_in;

motor_speed_out = speeds[10] * (spindle_speed_in / speeds[i+1]);

message = 0;

} else {

int j;

motor_speed_out = 0;

spindle_enable_out = 0;

for (j = 0; j < 10; j++) { message(j) = 0; }

message(i) = 1;

}

}

Last edit: 16 Sep 2018 10:26 by tecno. Reason: added text

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

18 Sep 2018 09:34 #117702

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I have now solved the puzzle and the comp works

Error was on this linesetp hm2_7i76e.0.7i76.0.0.spinout-scalemax adjusted accordingly and now set to 2585 and it is pretty much spot on at 500rpm.

Slightly nonlinear upwards but within acceptable tolerance.

Thanks for all the help to get this part of my milling machine project working.

Error was on this line

motor_speed_out = speeds[10] * (spindle_speed_in / speeds[i+1]);

correct line

motor_speed_out = speeds[10] * (spindle_speed_in / speeds[i]);Slightly nonlinear upwards but within acceptable tolerance.

Thanks for all the help to get this part of my milling machine project working.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.418 seconds