Search Results (Searched for: 7i76e)

- endian

17 Jul 2025 09:37

Reduce read-all timing 7i76e + 7i77 was created by endian

Reduce read-all timing 7i76e + 7i77

Category: Advanced Configuration

- G0G53Z148

16 Jul 2025 06:53

Replied by G0G53Z148 on topic Mesa Auswahl für größeres Projekt

Mesa Auswahl für größeres Projekt

Category: Deutsch

- PCW

10 Jul 2025 18:08

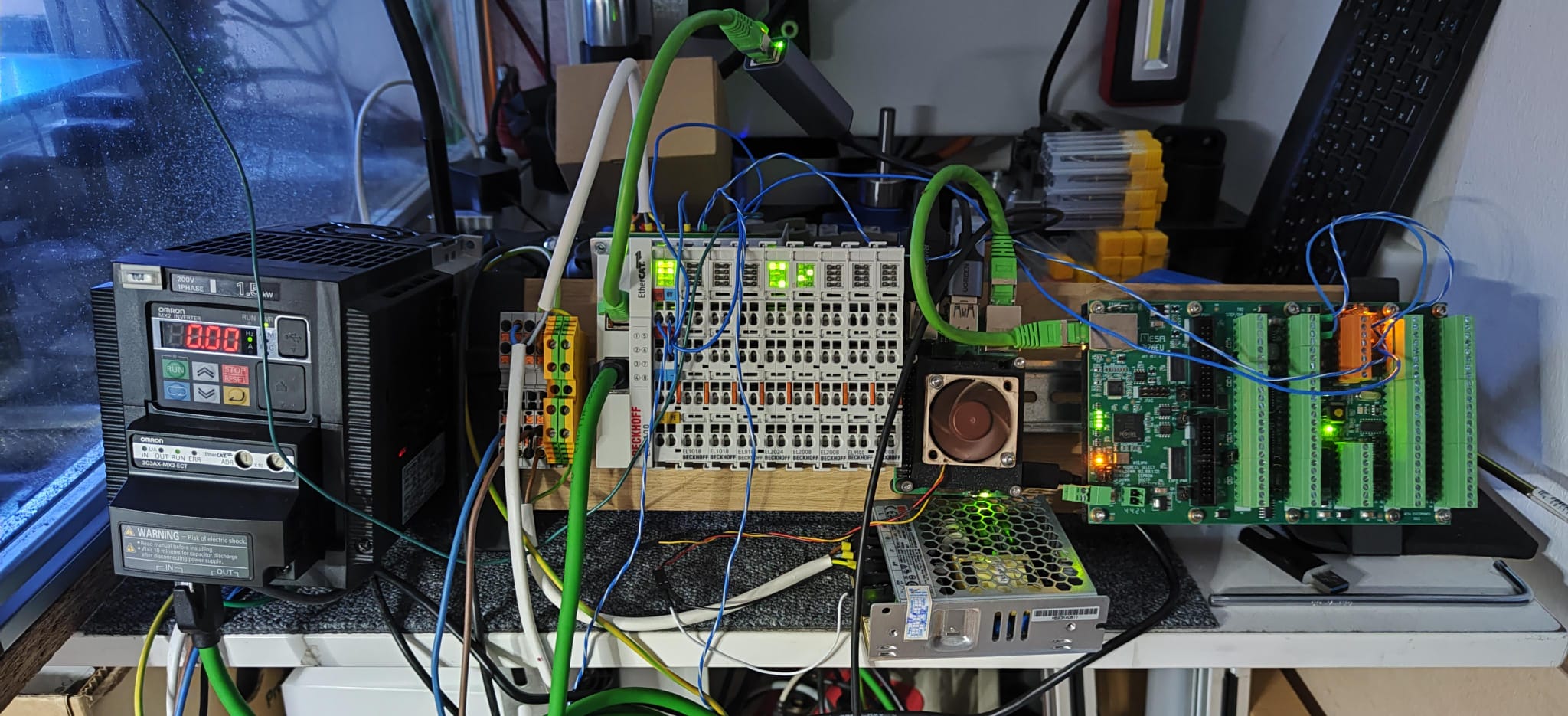

Replied by PCW on topic Noise issue related to mesa board 7I76E

Noise issue related to mesa board 7I76E

Category: Computers and Hardware

- tommylight

10 Jul 2025 15:30

Replied by tommylight on topic Noise issue related to mesa board 7I76E

Noise issue related to mesa board 7I76E

Category: Computers and Hardware

- unknown

- unknown

10 Jul 2025 08:22

Replied by unknown on topic Noise issue related to mesa board 7I76E

Noise issue related to mesa board 7I76E

Category: Computers and Hardware

- Daroum

- Daroum

10 Jul 2025 07:22

Noise issue related to mesa board 7I76E was created by Daroum

Noise issue related to mesa board 7I76E

Category: Computers and Hardware

- MikkelRS

08 Jul 2025 01:57

Using a 7i95T for 3 axis + handwheels was created by MikkelRS

Using a 7i95T for 3 axis + handwheels

Category: Advanced Configuration

- SjCNC

- SjCNC

07 Jul 2025 01:36

Replied by SjCNC on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- PCW

07 Jul 2025 00:57

Replied by PCW on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 23:54

Replied by SjCNC on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 20:46

Replied by SjCNC on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 16:26

Please help with adding laser control was created by SjCNC

Please help with adding laser control

Category: Plasma & Laser

- SebastianM

- SebastianM

04 Jul 2025 00:35 - 04 Jul 2025 02:01

- SebastianM

- SebastianM

29 Jun 2025 16:10 - 29 Jun 2025 16:14

Replied by SebastianM on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

Time to create page: 0.888 seconds