Search Results (Searched for: 7i76e)

05 Nov 2023 00:40

04 Nov 2023 23:47

04 Nov 2023 23:30

04 Nov 2023 23:26

Replied by tommylight on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

04 Nov 2023 23:04

Replied by gardenweazel on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

04 Nov 2023 22:41

03 Nov 2023 20:32

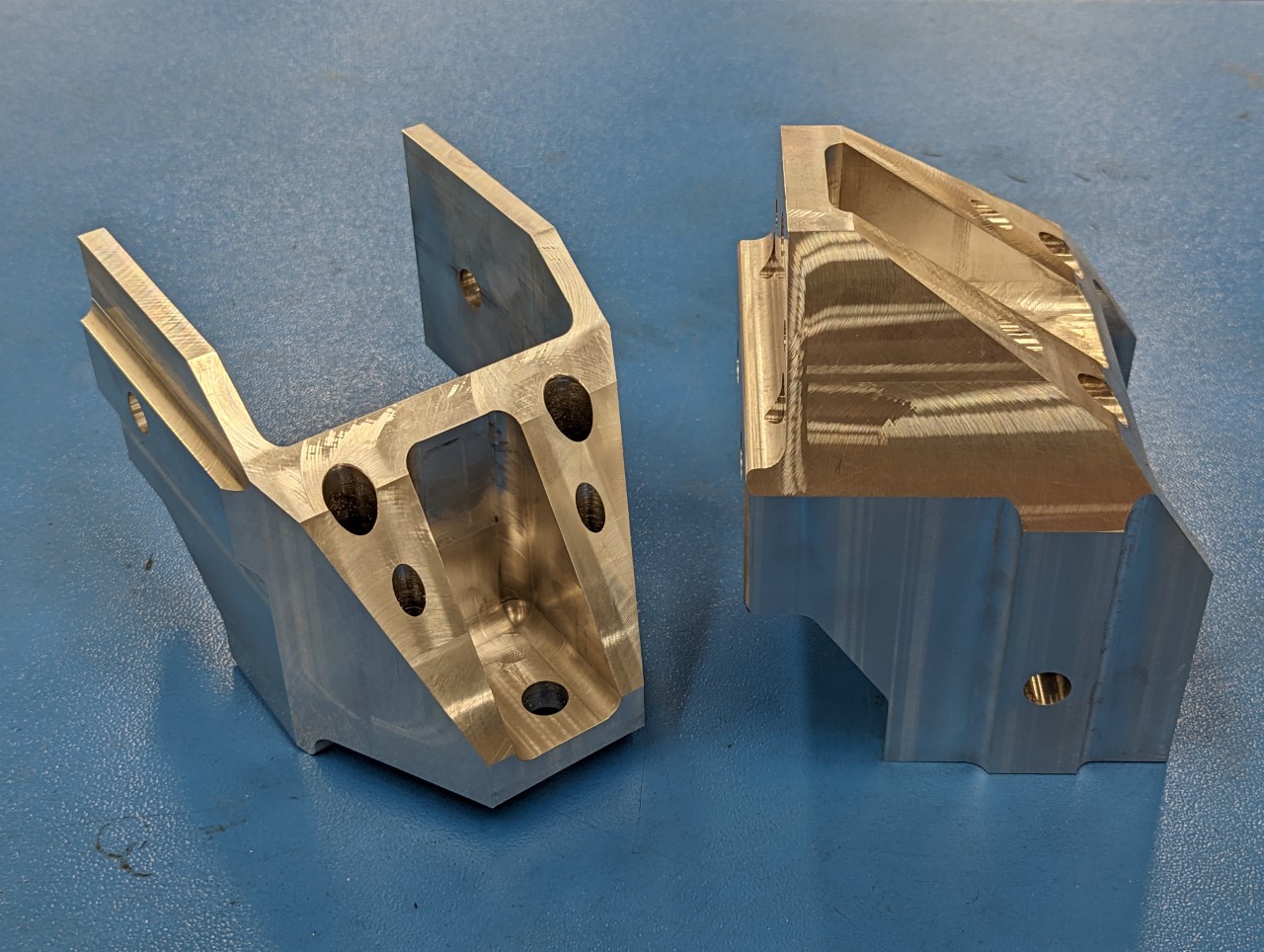

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

03 Nov 2023 17:55 - 03 Nov 2023 22:22

Optimum Optimill MH50V CNC conversion was created by Unlogic

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

01 Nov 2023 21:55

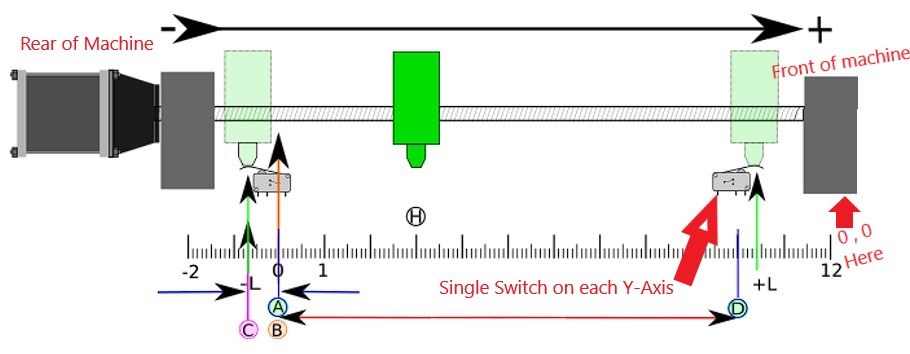

Replied by tommylight on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

01 Nov 2023 18:55

Replied by gardenweazel on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 22:07

Replied by tommylight on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 21:51

Replied by gardenweazel on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 20:19 - 31 Oct 2023 20:30

Replied by tommylight on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 17:53

Replied by djdelorie on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

31 Oct 2023 17:33 - 31 Oct 2023 21:07

Replied by PCW on topic Tandem Y Axis not working on 7i76E

Tandem Y Axis not working on 7i76E

Category: General LinuxCNC Questions

Time to create page: 0.993 seconds