Search Results (Searched for: THCAD)

- sin-do-re

- sin-do-re

15 Oct 2025 08:28

THC qtplasmac 2.9 is moving UP when it should be moving DOWN was created by sin-do-re

THC qtplasmac 2.9 is moving UP when it should be moving DOWN

Category: General LinuxCNC Questions

- PCW

14 Oct 2025 22:44 - 14 Oct 2025 22:47

Replied by PCW on topic 7i97t and qtplasmac

7i97t and qtplasmac

Category: General LinuxCNC Questions

- tommylight

13 Oct 2025 09:03

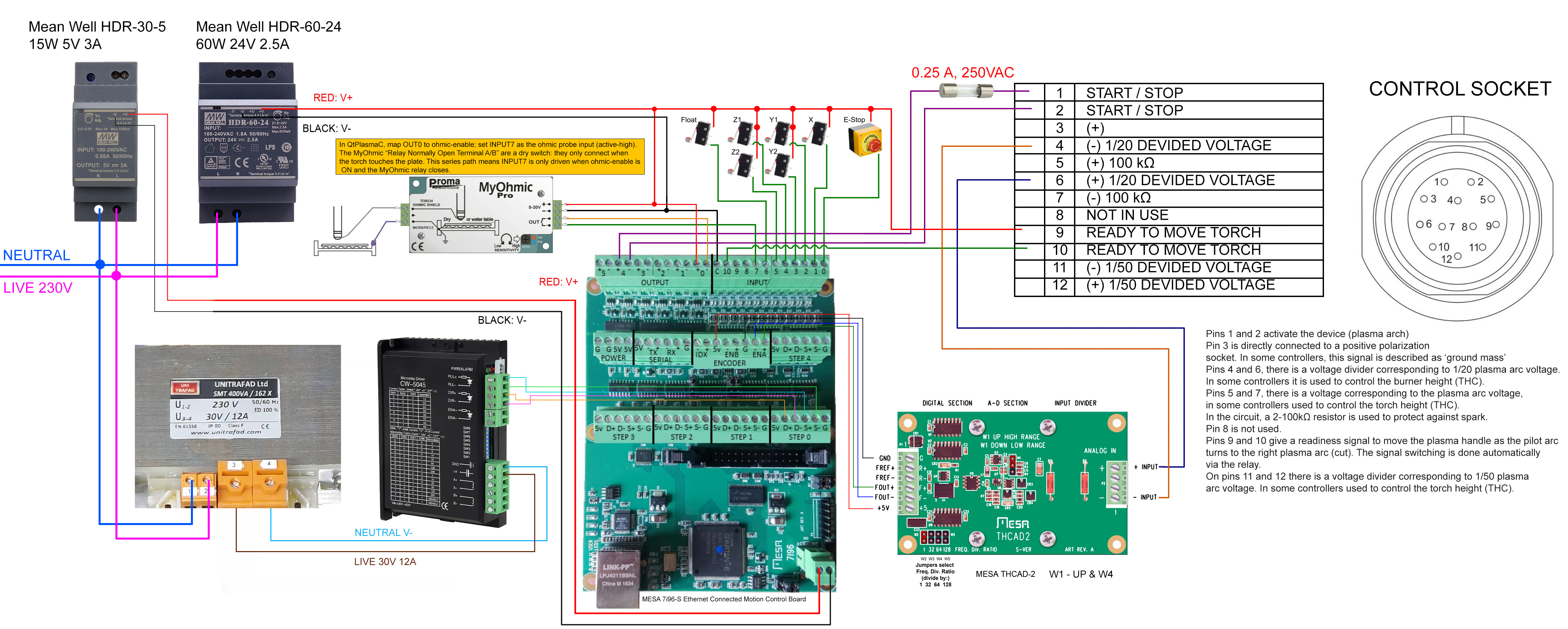

Replied by tommylight on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Category: Driver Boards

- GuessWho

- GuessWho

13 Oct 2025 08:11

- PCW

12 Oct 2025 20:00

- rodw

12 Oct 2025 19:08

- Hakan

- Hakan

12 Oct 2025 18:32

- andypugh

12 Oct 2025 16:04

- GuessWho

- GuessWho

12 Oct 2025 12:38 - 12 Oct 2025 12:47

- tommylight

04 Oct 2025 00:21

Replied by tommylight on topic Hypertherm hsd130 interface

Hypertherm hsd130 interface

Category: Plasma & Laser

- bentiggin

- bentiggin

25 Sep 2025 01:19

Replied by bentiggin on topic Hypertherm hsd130 interface

Hypertherm hsd130 interface

Category: Plasma & Laser

- bentiggin

- bentiggin

25 Sep 2025 00:12

Hypertherm hsd130 interface was created by bentiggin

Hypertherm hsd130 interface

Category: Plasma & Laser

- souh-hil

18 Sep 2025 19:07

Firmware Request for 7i92 – Plasma CNC Build was created by souh-hil

Firmware Request for 7i92 – Plasma CNC Build

Category: Driver Boards

- mal136

- mal136

11 Sep 2025 15:27

- tommylight

01 Sep 2025 12:17

Replied by tommylight on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Category: Show Your Stuff

Time to create page: 2.083 seconds