Search Results (Searched for: )

- tommylight

12 Apr 2025 14:31

- pgf

- pgf

12 Apr 2025 14:23

Replied by pgf on topic Running an external program from a HAL pin

Running an external program from a HAL pin

Category: HAL

- PCW

12 Apr 2025 14:09

- dm17ry

12 Apr 2025 14:02

- workaholic

12 Apr 2025 13:53 - 12 Apr 2025 13:54

Replied by workaholic on topic CamWorks (Solidworks) Post processor

CamWorks (Solidworks) Post processor

Category: Post Processors

- ErwinCNC

- ErwinCNC

12 Apr 2025 13:28

- meister

- meister

12 Apr 2025 12:14

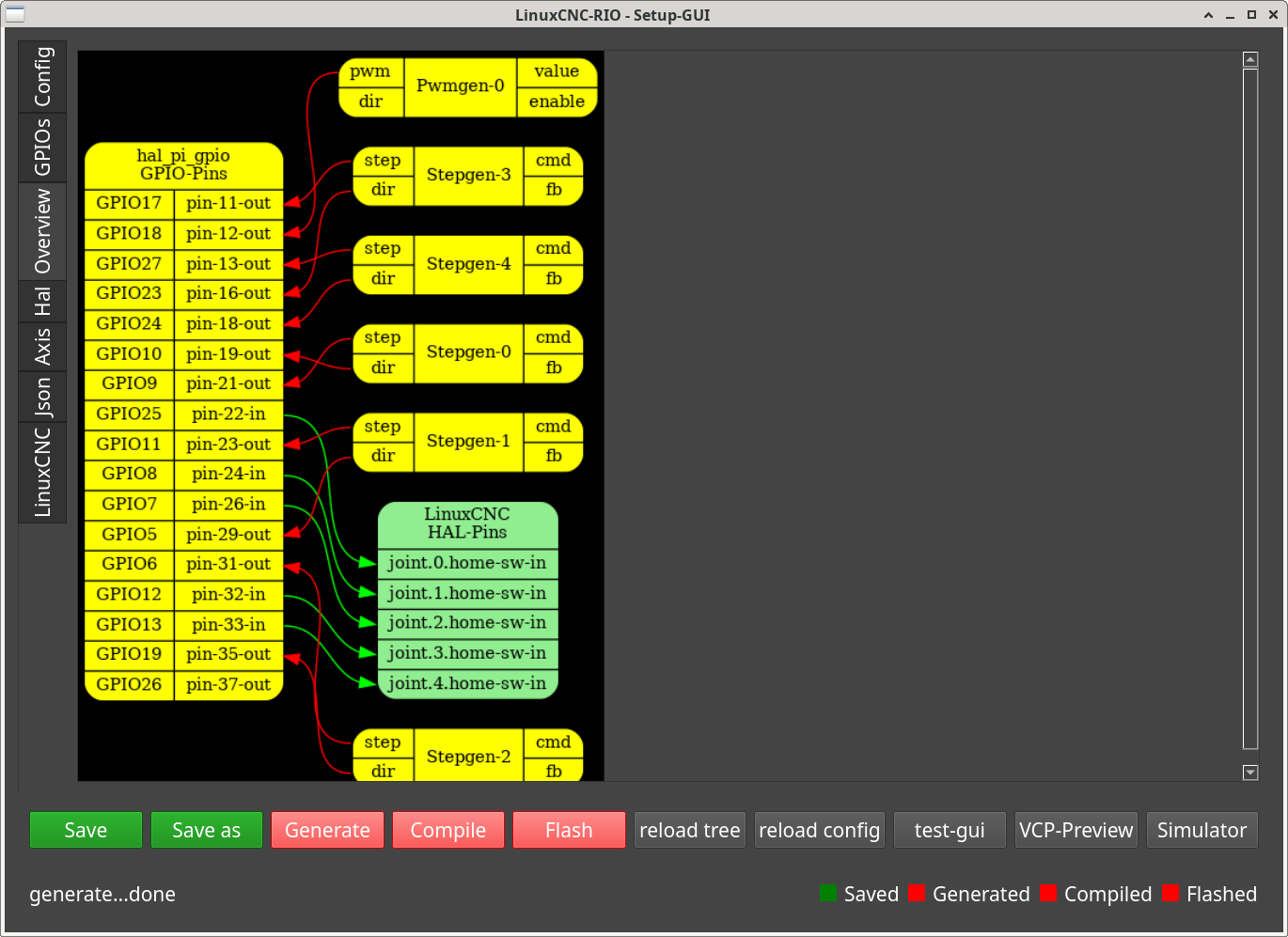

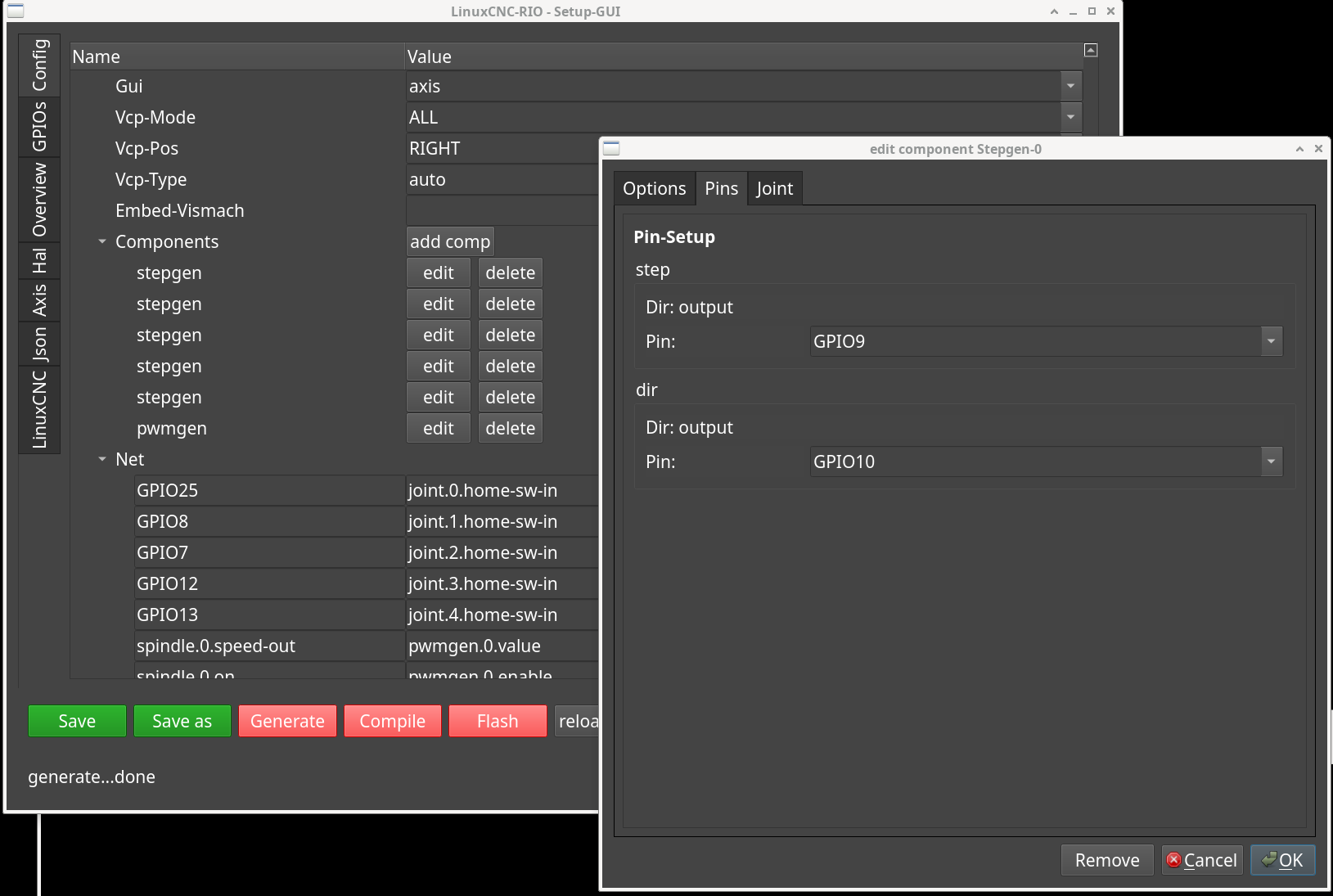

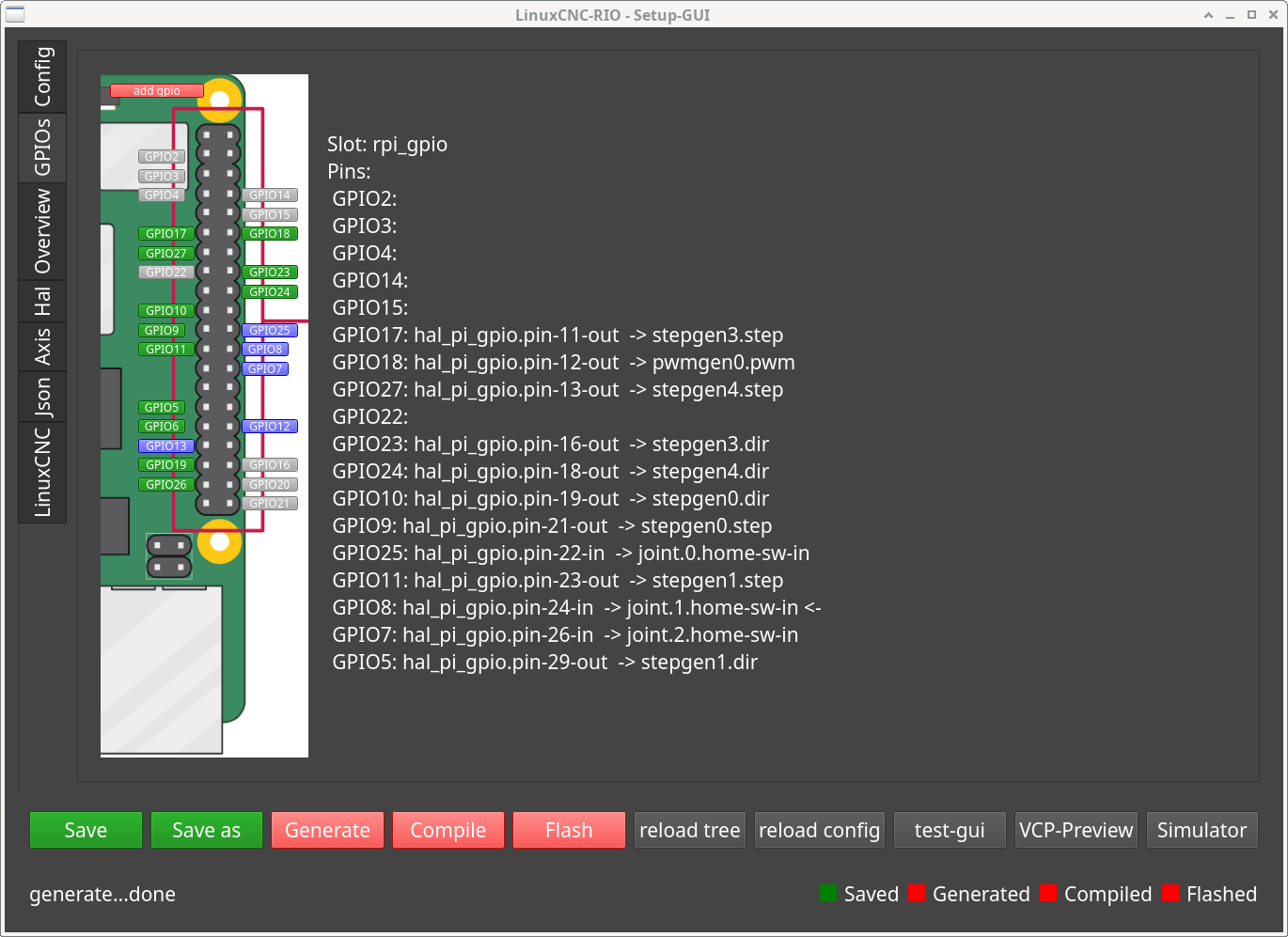

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- jpg

- jpg

12 Apr 2025 11:43

Replied by jpg on topic Hydraulic Linear Motion Precision Controll

Hydraulic Linear Motion Precision Controll

Category: Advanced Configuration

- unknown

- unknown

12 Apr 2025 11:29

- Millimetergott

- Millimetergott

12 Apr 2025 11:15 - 16 Apr 2025 14:04

- jpg

- jpg

12 Apr 2025 11:05

Replied by jpg on topic 3D Scanners Who Has Used Them?

3D Scanners Who Has Used Them?

Category: Additive Manufacturing

- vanhalen90

- vanhalen90

12 Apr 2025 10:41

Replied by vanhalen90 on topic Hydraulic Linear Motion Precision Controll

Hydraulic Linear Motion Precision Controll

Category: Advanced Configuration

- rodw

12 Apr 2025 10:15

- jelost

- jelost

12 Apr 2025 10:05

Replied by jelost on topic Comment utiliser le signal d'un capteur

Comment utiliser le signal d'un capteur

Category: Français

- Ismacr63

- Ismacr63

12 Apr 2025 09:38 - 12 Apr 2025 09:44

Time to create page: 0.635 seconds