Search Results (Searched for: )

- Aciera

10 Mar 2025 16:54

Replied by Aciera on topic Delta VFD-B Modbus with QtDragon_hd

Delta VFD-B Modbus with QtDragon_hd

Category: General LinuxCNC Questions

- Todd Zuercher

10 Mar 2025 16:35

Replied by Todd Zuercher on topic QTplasmaC upgrade now huge latency

QTplasmaC upgrade now huge latency

Category: Computers and Hardware

- Todd Zuercher

10 Mar 2025 16:22 - 10 Mar 2025 16:24

Replied by Todd Zuercher on topic Error when starting LinuxCNC: “undefined symbol: kinematicsSwitch”

Error when starting LinuxCNC: “undefined symbol: kinematicsSwitch”

Category: General LinuxCNC Questions

- robh

- robh

10 Mar 2025 16:15

Replied by robh on topic Joint Error After large rotary move

Joint Error After large rotary move

Category: General LinuxCNC Questions

- fabi0696

- fabi0696

10 Mar 2025 15:41

Replied by fabi0696 on topic EL6731 changes cyclically to INIT status

EL6731 changes cyclically to INIT status

Category: EtherCAT

- workshop54

- workshop54

10 Mar 2025 15:24

Retrofit: Maho MH400E to LinuxCNC was created by workshop54

Retrofit: Maho MH400E to LinuxCNC

Category: Show Your Stuff

- low-blip

- low-blip

10 Mar 2025 15:15

- workshop54

- workshop54

10 Mar 2025 15:06

- Hakan

- Hakan

10 Mar 2025 14:23

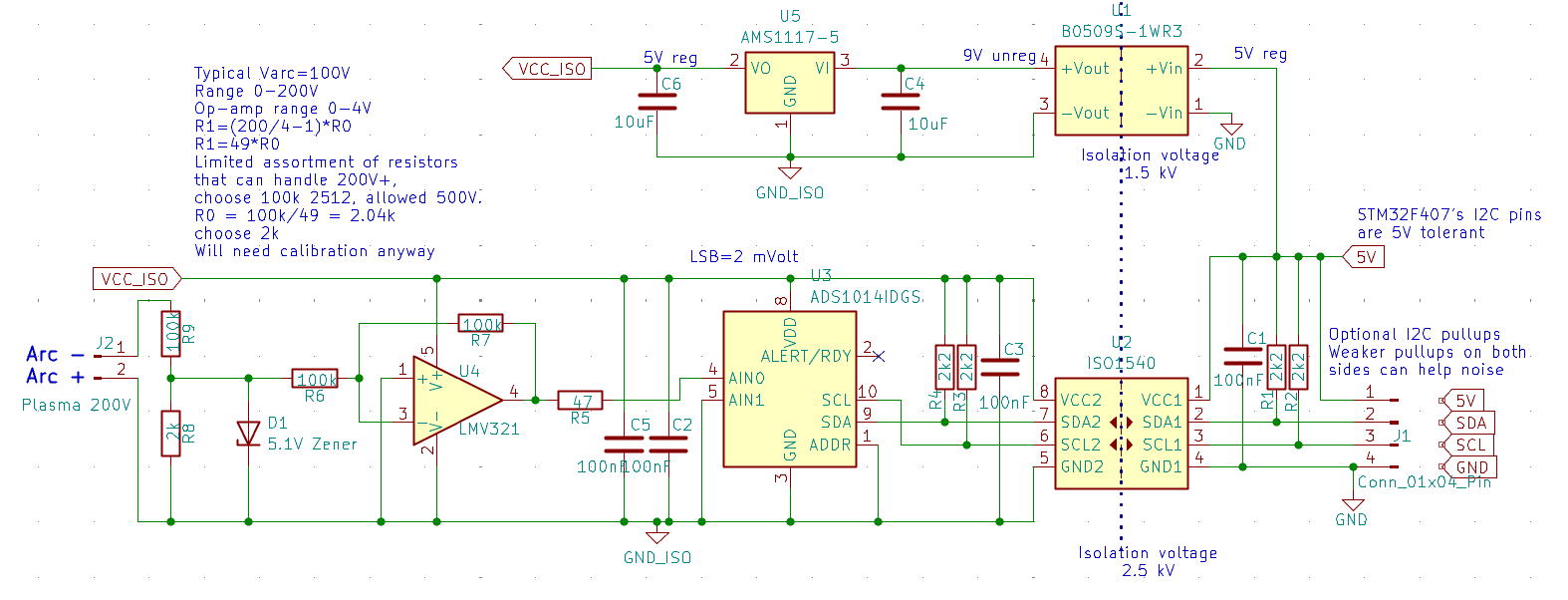

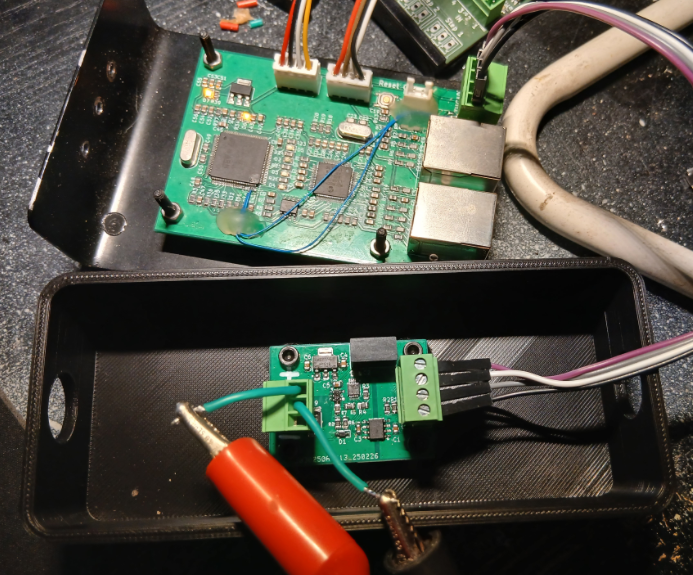

Replied by Hakan on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- JTknives

10 Mar 2025 14:20

QTplasmaC upgrade now huge latency was created by JTknives

QTplasmaC upgrade now huge latency

Category: Computers and Hardware

- Todd Zuercher

10 Mar 2025 14:19

Replied by Todd Zuercher on topic halui toggle button

halui toggle button

Category: Basic Configuration

- emcPT

10 Mar 2025 14:10

Replied by emcPT on topic MBT -> GPT to reuse existing installation

MBT -> GPT to reuse existing installation

Category: Installing LinuxCNC

- Todd Zuercher

10 Mar 2025 13:36

Replied by Todd Zuercher on topic Delta VFD-B Modbus with QtDragon_hd

Delta VFD-B Modbus with QtDragon_hd

Category: General LinuxCNC Questions

- endian

10 Mar 2025 13:28

Replied by endian on topic EL6731 changes cyclically to INIT status

EL6731 changes cyclically to INIT status

Category: EtherCAT

- Grotius

10 Mar 2025 12:35

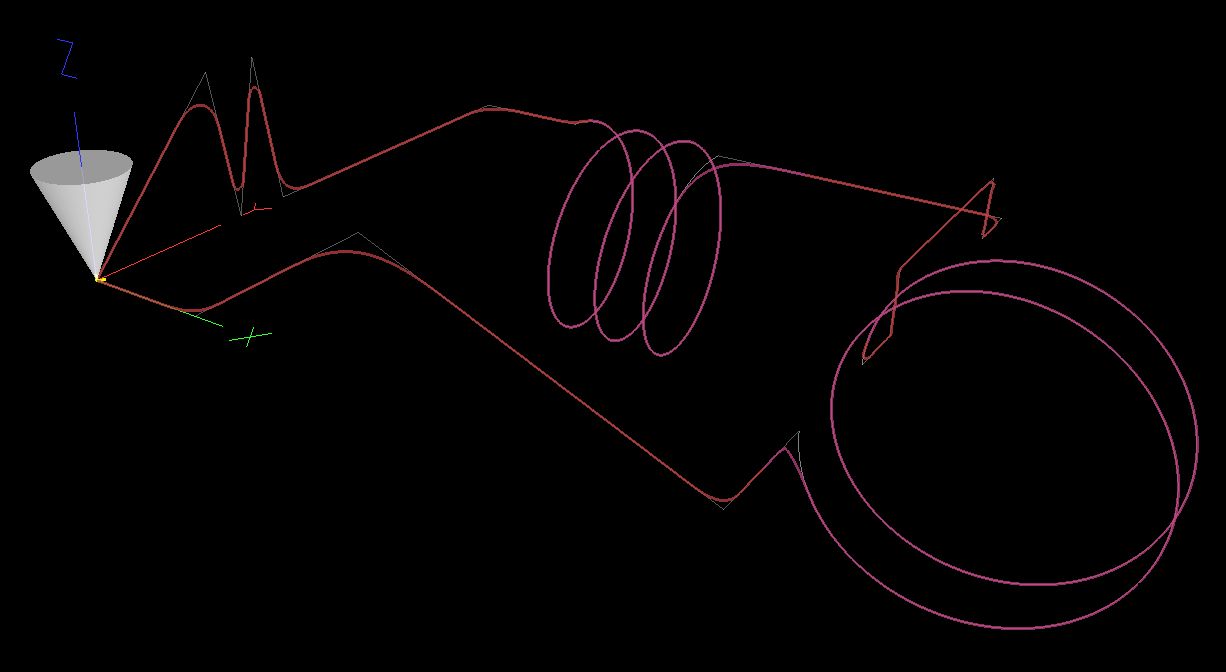

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

Time to create page: 0.719 seconds