Search Results (Searched for: )

- notJamesLee

- notJamesLee

07 Feb 2025 05:02

Replied by notJamesLee on topic Installing NoMachine Remote Desktop - Package installer issues

Installing NoMachine Remote Desktop - Package installer issues

Category: Computers and Hardware

- notJamesLee

- notJamesLee

07 Feb 2025 04:59

Replied by notJamesLee on topic Tandem Motor Free to Turn - Mesa 7i96s

Tandem Motor Free to Turn - Mesa 7i96s

Category: Basic Configuration

- Mr. Mass

07 Feb 2025 04:39

- notJamesLee

- notJamesLee

07 Feb 2025 04:00

- PCW

07 Feb 2025 03:55 - 07 Feb 2025 04:16

Replied by PCW on topic Tandem Motor Free to Turn - Mesa 7i96s

Tandem Motor Free to Turn - Mesa 7i96s

Category: Basic Configuration

- notJamesLee

- notJamesLee

07 Feb 2025 03:46

Tandem Motor Free to Turn - Mesa 7i96s was created by notJamesLee

Tandem Motor Free to Turn - Mesa 7i96s

Category: Basic Configuration

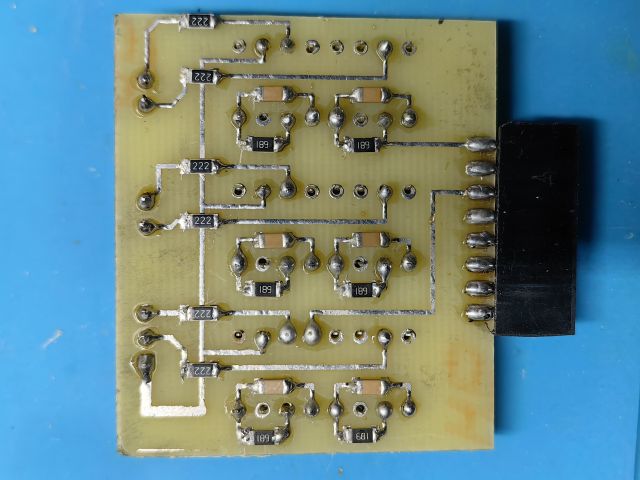

- GeckoWorks

- GeckoWorks

07 Feb 2025 03:41 - 07 Feb 2025 03:58

- unknown

- unknown

07 Feb 2025 02:27

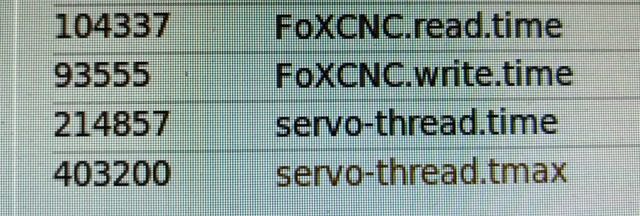

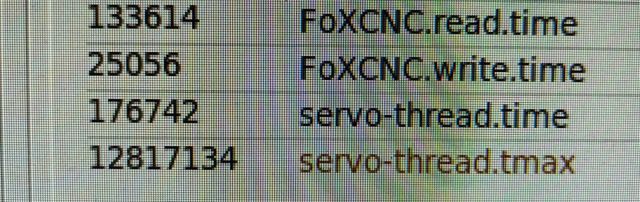

Replied by unknown on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- phillc54

07 Feb 2025 02:11

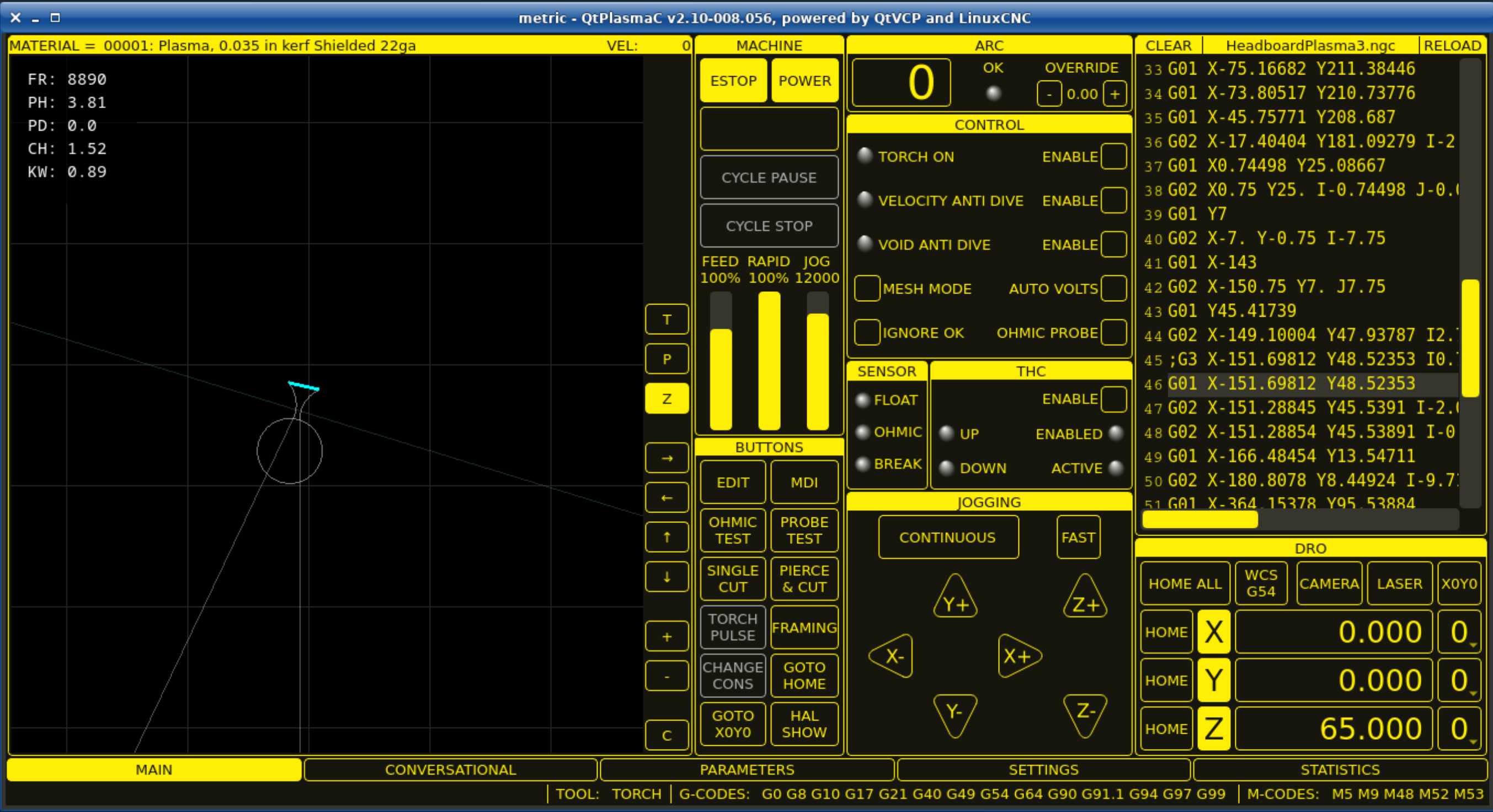

Replied by phillc54 on topic Errors with G code for Qtpalmac

Errors with G code for Qtpalmac

Category: Fusion 360

- Lisov_R

- Lisov_R

07 Feb 2025 01:48

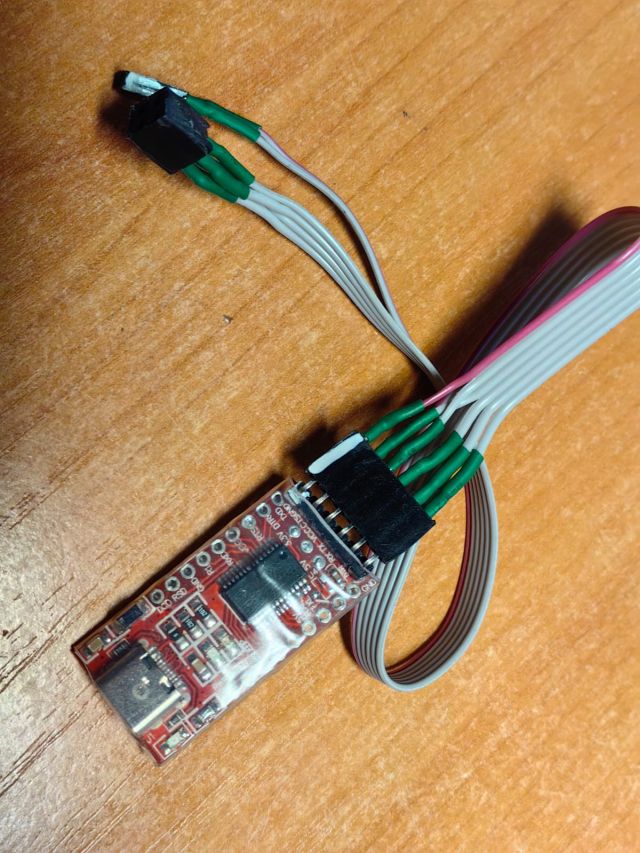

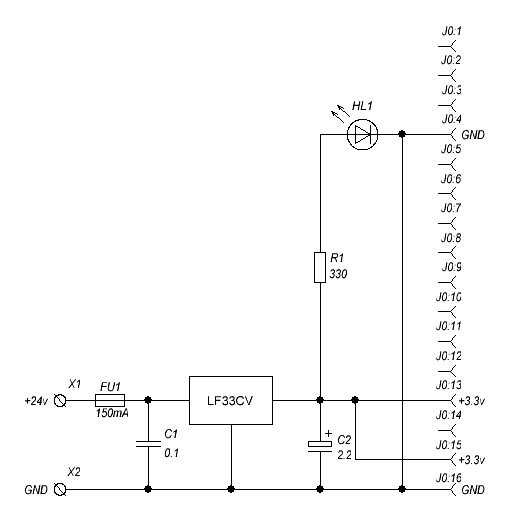

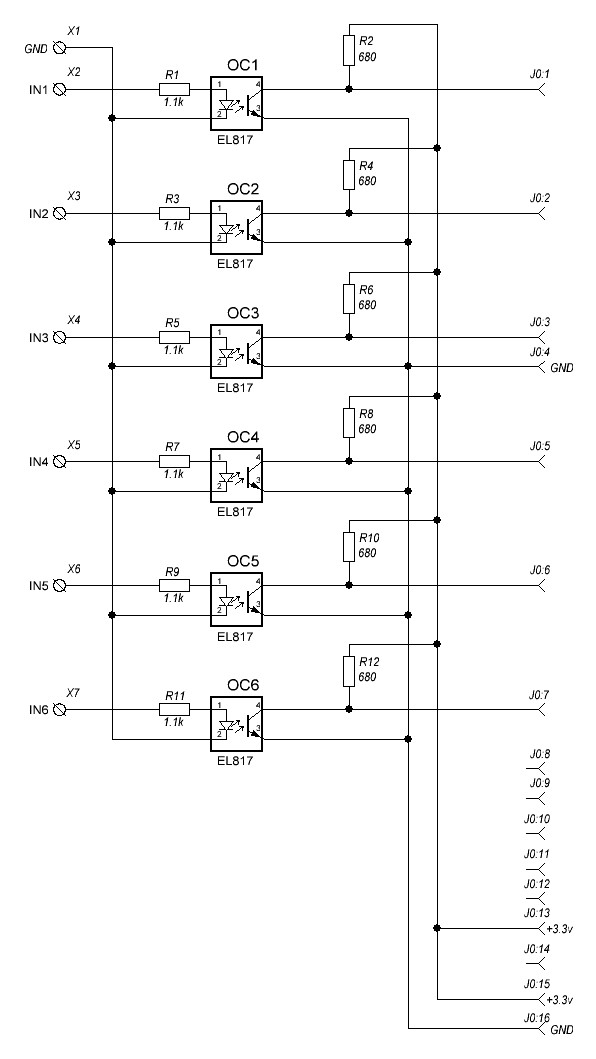

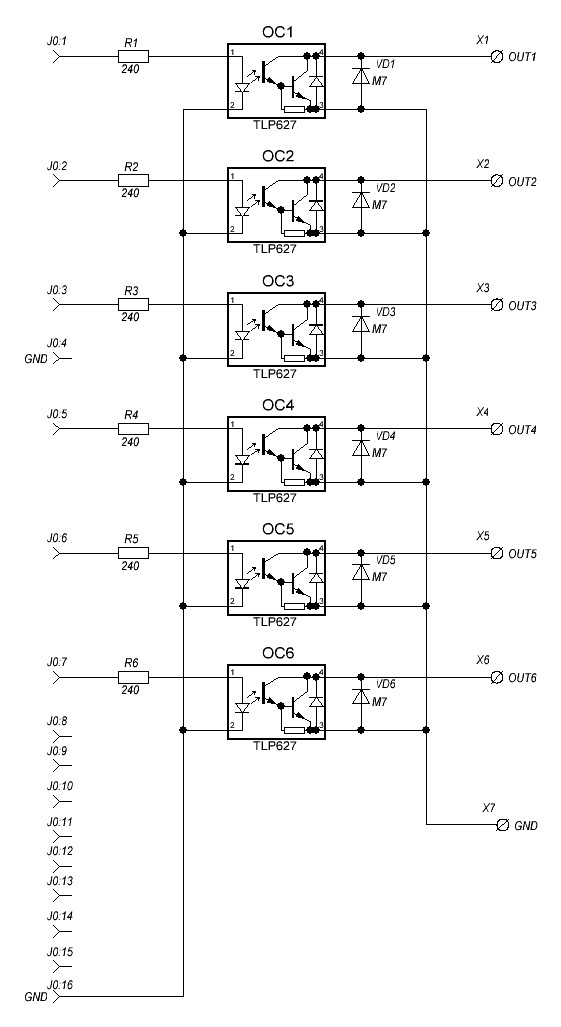

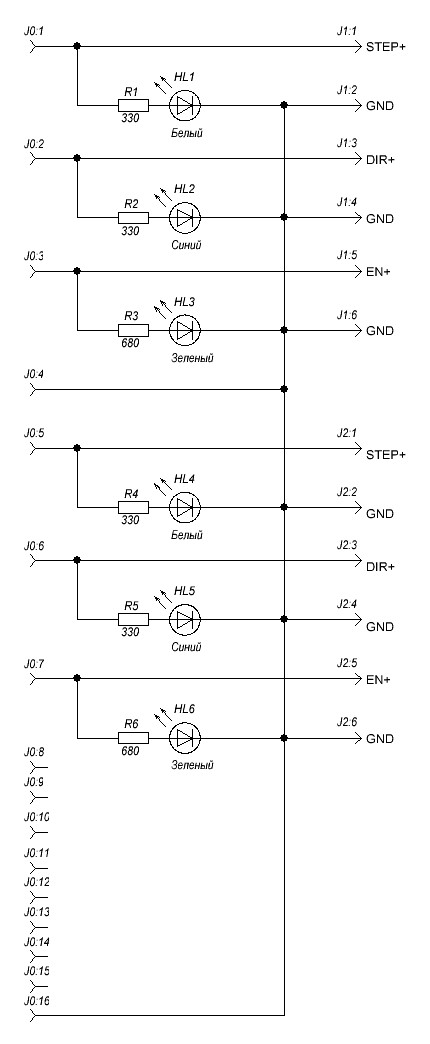

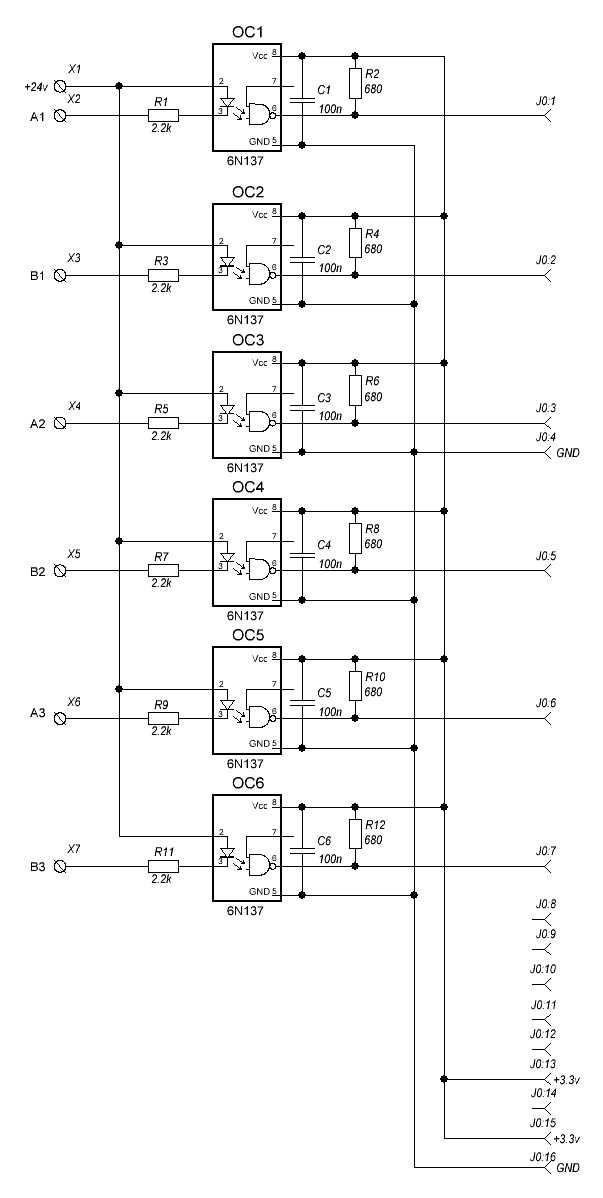

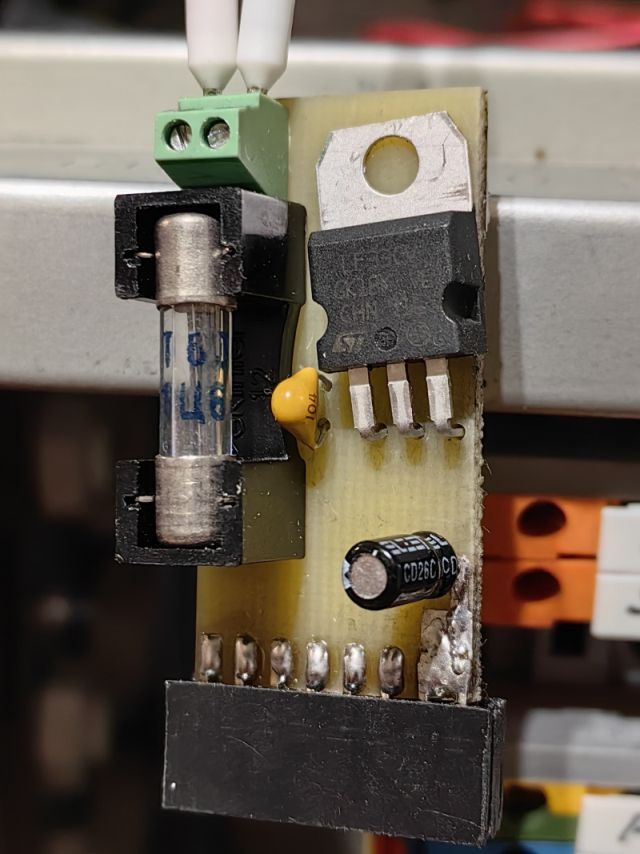

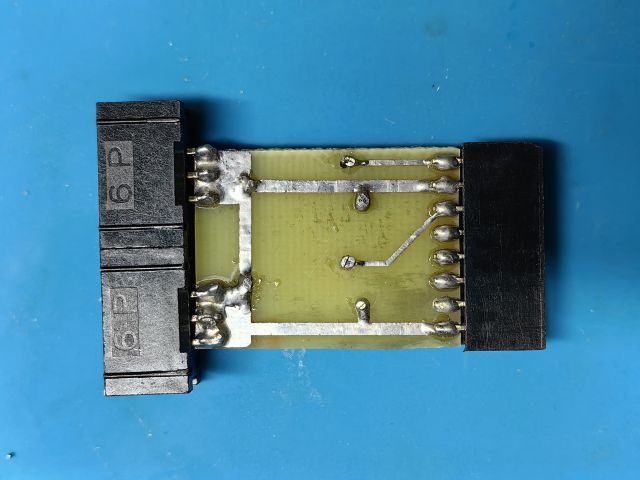

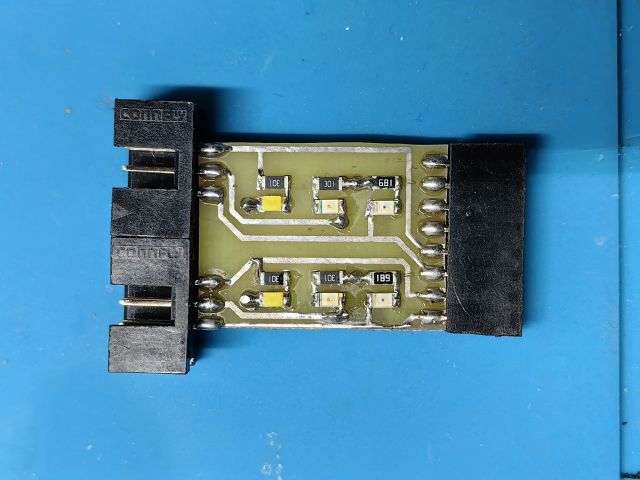

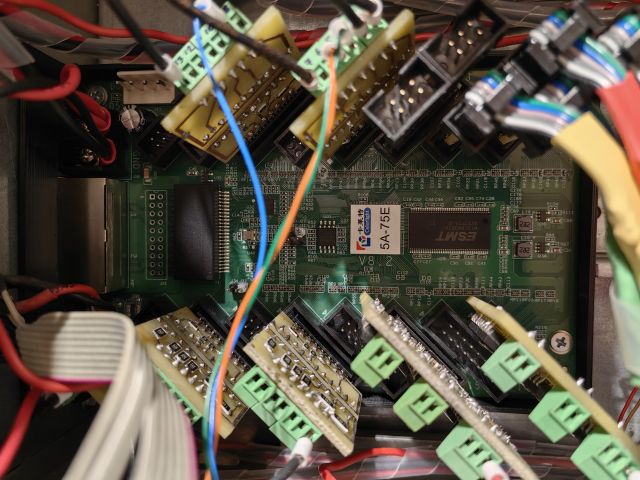

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Lisov_R

- Lisov_R

07 Feb 2025 01:44

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Lisov_R

- Lisov_R

07 Feb 2025 01:37 - 07 Feb 2025 01:42

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Lisov_R

- Lisov_R

07 Feb 2025 01:31

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Lisov_R

- Lisov_R

07 Feb 2025 01:26 - 07 Feb 2025 01:27

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Lisov_R

- Lisov_R

07 Feb 2025 01:21

Replied by Lisov_R on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

Time to create page: 0.745 seconds