Search Results (Searched for: )

- Tchefter

17 Dec 2024 15:50 - 17 Dec 2024 15:52

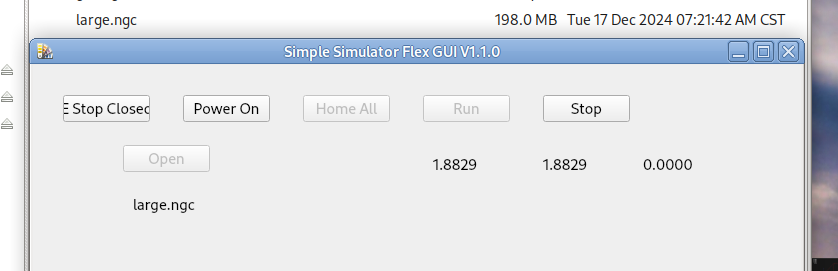

Replied by Tchefter on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- CNC_ANDI

- CNC_ANDI

17 Dec 2024 15:49 - 17 Dec 2024 15:51

- Hendrixx

- Hendrixx

17 Dec 2024 15:46 - 17 Dec 2024 23:16

Replied by Hendrixx on topic Anyone use digital signals to connect 7i96 to a VFD?

Anyone use digital signals to connect 7i96 to a VFD?

Category: General LinuxCNC Questions

- PCW

17 Dec 2024 15:43

- meister

- meister

17 Dec 2024 15:42 - 17 Dec 2024 15:47

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- jyeomans

- jyeomans

17 Dec 2024 15:25

- digiex_chris

- digiex_chris

17 Dec 2024 15:21

Replied by digiex_chris on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- digiex_chris

- digiex_chris

17 Dec 2024 15:04

Replied by digiex_chris on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Lcvette

17 Dec 2024 14:31 - 17 Dec 2024 14:34

Replied by Lcvette on topic Specified probe tool not in spindle error after upgrade

Specified probe tool not in spindle error after upgrade

Category: QtPyVCP

- Unlogic

- Unlogic

17 Dec 2024 14:29

Replied by Unlogic on topic Specified probe tool not in spindle error after upgrade

Specified probe tool not in spindle error after upgrade

Category: QtPyVCP

- Lcvette

17 Dec 2024 14:25

Replied by Lcvette on topic Specified probe tool not in spindle error after upgrade

Specified probe tool not in spindle error after upgrade

Category: QtPyVCP

- EragonPower

17 Dec 2024 14:22

Replied by EragonPower on topic IHSV60 integrated servo moves when removing power or disabling it

IHSV60 integrated servo moves when removing power or disabling it

Category: CNC Machines

- Lcvette

17 Dec 2024 14:08

- mariusl

17 Dec 2024 13:56 - 17 Dec 2024 14:07

- JT

17 Dec 2024 13:25

Time to create page: 1.937 seconds