Search Results (Searched for: )

- seebaer1976

- seebaer1976

14 Dec 2024 16:54 - 15 Dec 2024 09:16

Replied by seebaer1976 on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- seebaer1976

- seebaer1976

14 Dec 2024 16:05

Replied by seebaer1976 on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- PCW

14 Dec 2024 15:33

Replied by PCW on topic Weiler DZ26 Millturn Conversion

Weiler DZ26 Millturn Conversion

Category: Turning

- PCW

14 Dec 2024 15:27

Replied by PCW on topic Same settings, different result

Same settings, different result

Category: Basic Configuration

- PCW

14 Dec 2024 15:19 - 14 Dec 2024 15:20

Replied by PCW on topic Teknic Clearpath SDSK wiring to 7i96s

Teknic Clearpath SDSK wiring to 7i96s

Category: General LinuxCNC Questions

- gardenweazel

14 Dec 2024 14:41

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- MacKaye

- MacKaye

14 Dec 2024 14:32

Replied by MacKaye on topic Weiler DZ26 Millturn Conversion

Weiler DZ26 Millturn Conversion

Category: Turning

- gardenweazel

14 Dec 2024 14:20 - 14 Dec 2024 14:23

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- tommylight

14 Dec 2024 14:05

Replied by tommylight on topic Improving Base Thread Jitter

Improving Base Thread Jitter

Category: Installing LinuxCNC

- Lcvette

14 Dec 2024 14:02

Replied by Lcvette on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

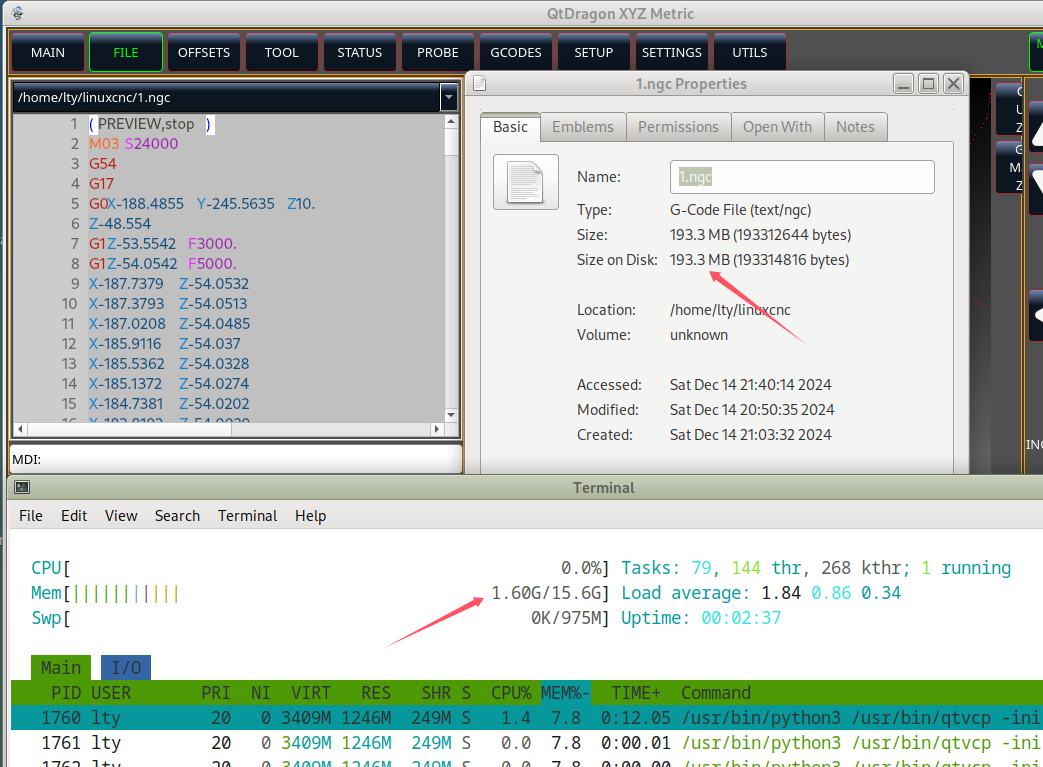

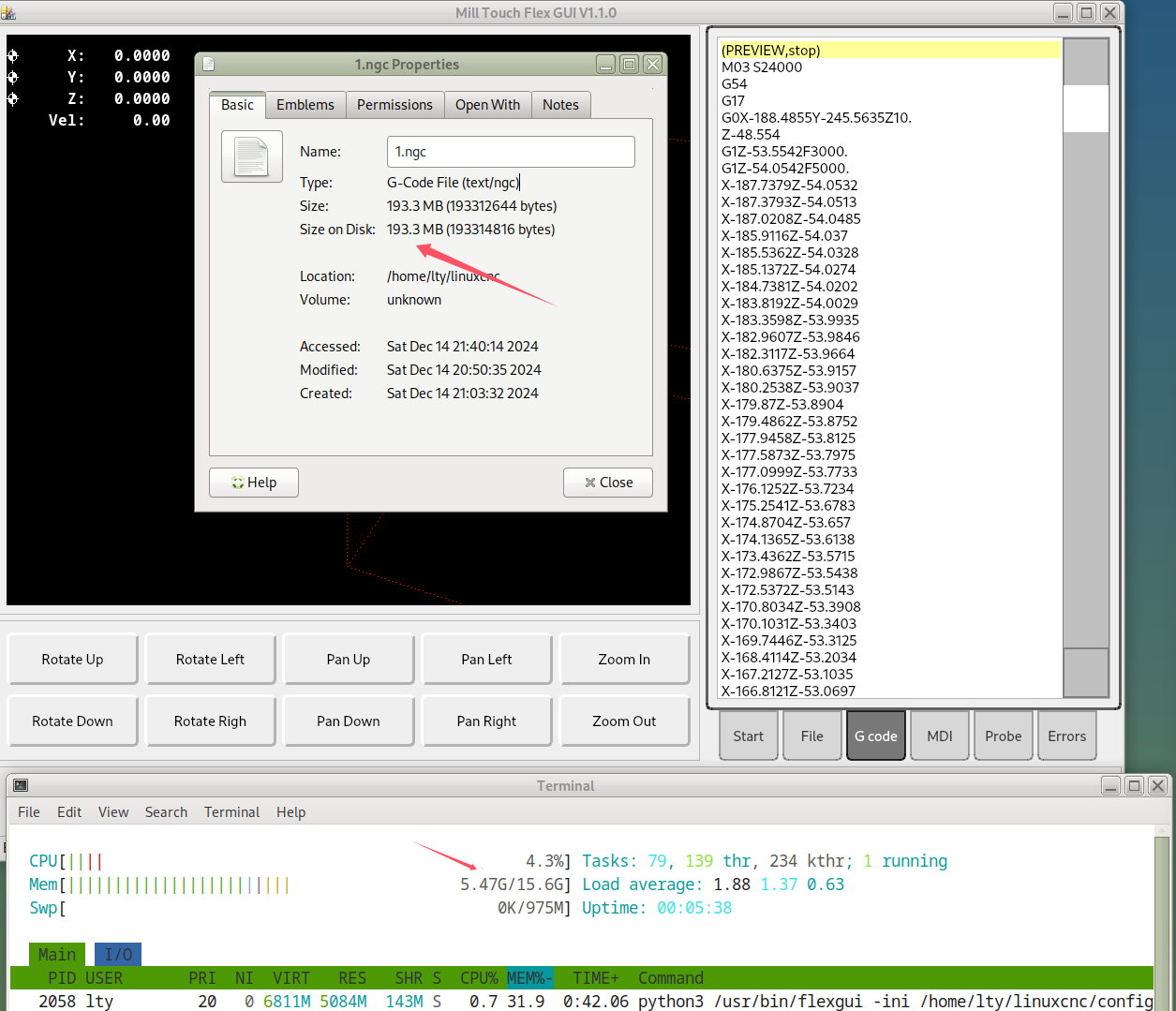

- kjlty

- kjlty

14 Dec 2024 14:01

- kjlty

- kjlty

14 Dec 2024 13:56

- Lcvette

14 Dec 2024 13:31

Time to create page: 0.671 seconds