Search Results (Searched for: )

- Bari

06 Jul 2024 18:09 - 06 Jul 2024 18:12

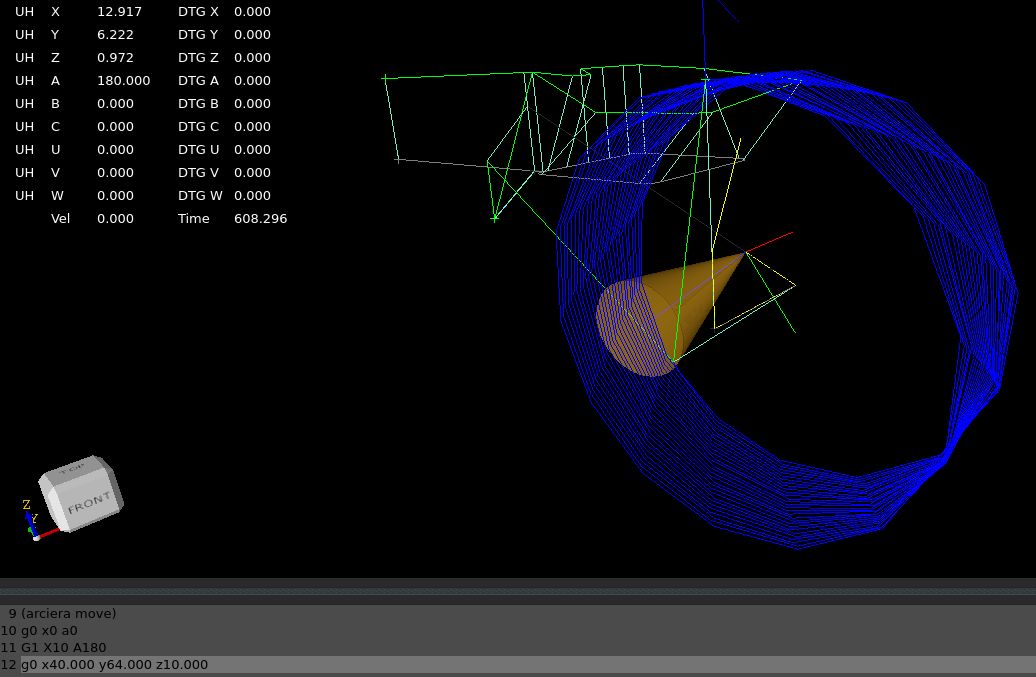

Replied by Bari on topic LinuxCNC for SLA, DLP and mSLA/mLCD Printers

LinuxCNC for SLA, DLP and mSLA/mLCD Printers

Category: Show Your Stuff

- PCW

06 Jul 2024 17:24

- Aciera

06 Jul 2024 15:54

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- zjjxxsh

- zjjxxsh

06 Jul 2024 15:45

- tommylight

06 Jul 2024 15:42

Replied by tommylight on topic Update causes an error on startup..fix

Update causes an error on startup..fix

Category: QtPyVCP

- PCW

06 Jul 2024 15:22

Replied by PCW on topic BLDC component with 8i20 - how to get to work?

BLDC component with 8i20 - how to get to work?

Category: Driver Boards

- Irritant

- Irritant

06 Jul 2024 15:13

Replied by Irritant on topic Router Will not run

Router Will not run

Category: General LinuxCNC Questions

- Grotius

06 Jul 2024 15:02 - 06 Jul 2024 15:05

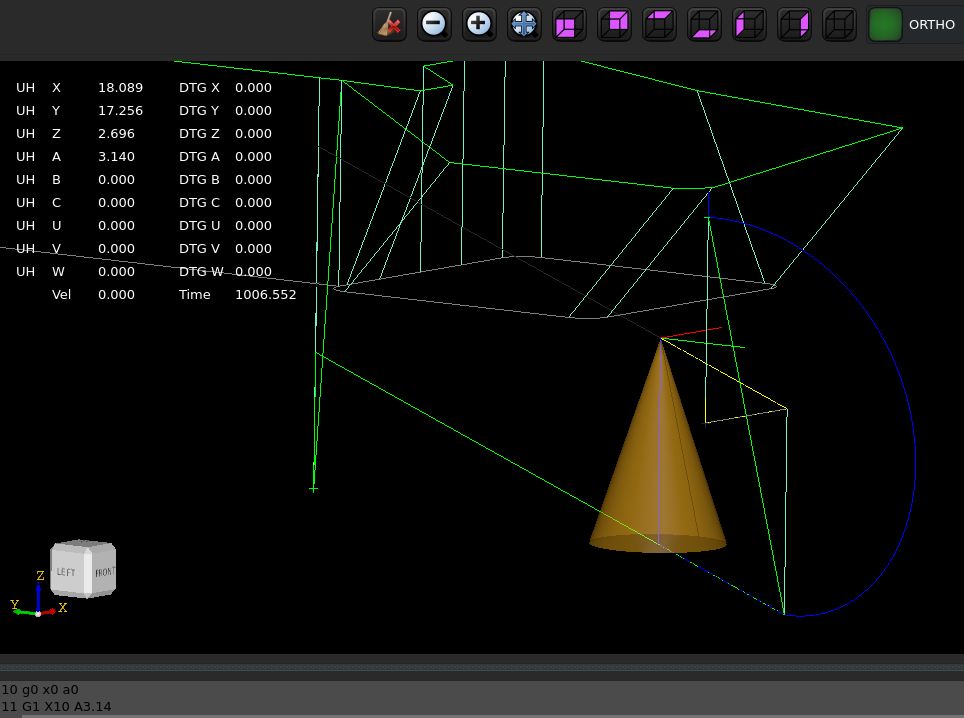

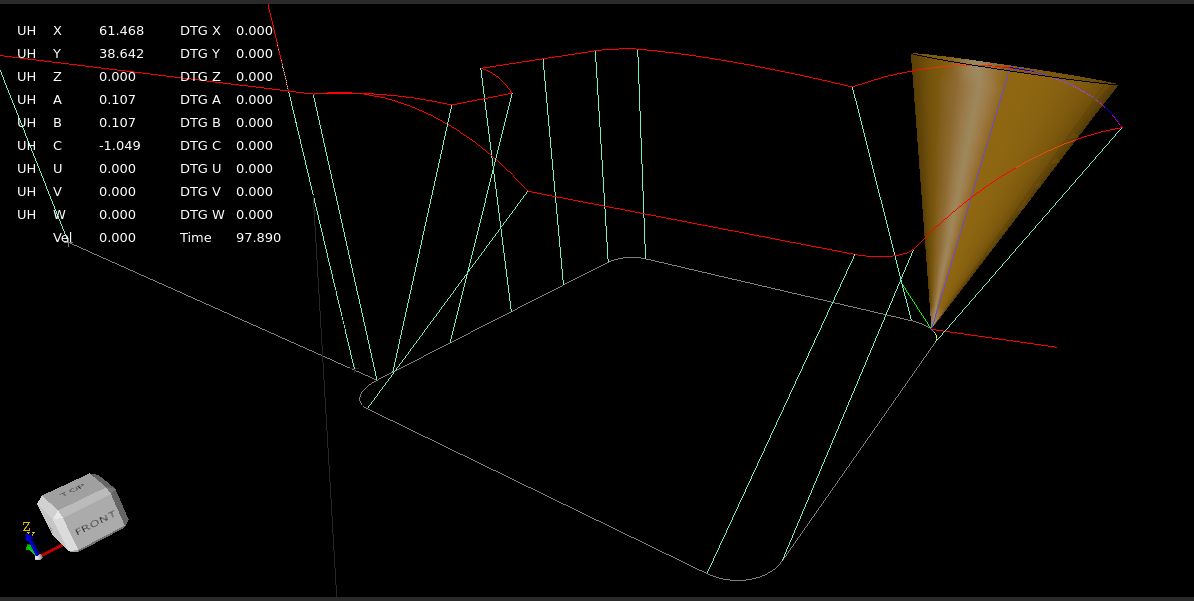

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Donb9261

06 Jul 2024 14:55

- Project_Hopeless

06 Jul 2024 14:44

Replied by Project_Hopeless on topic 7i96s Board Firmware

7i96s Board Firmware

Category: Driver Boards

- blazini36

- blazini36

06 Jul 2024 13:51

- Aciera

06 Jul 2024 13:42 - 06 Jul 2024 13:58

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- garthnoakes

- garthnoakes

06 Jul 2024 13:14

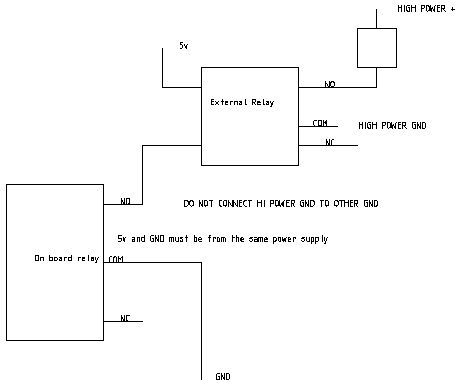

Replied by garthnoakes on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- Cant do this anymore bye all

06 Jul 2024 13:12 - 06 Jul 2024 13:26

Replied by Cant do this anymore bye all on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- garthnoakes

- garthnoakes

06 Jul 2024 13:12

Replied by garthnoakes on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

Time to create page: 0.689 seconds