Search Results (Searched for: )

- Aciera

21 Feb 2025 06:30

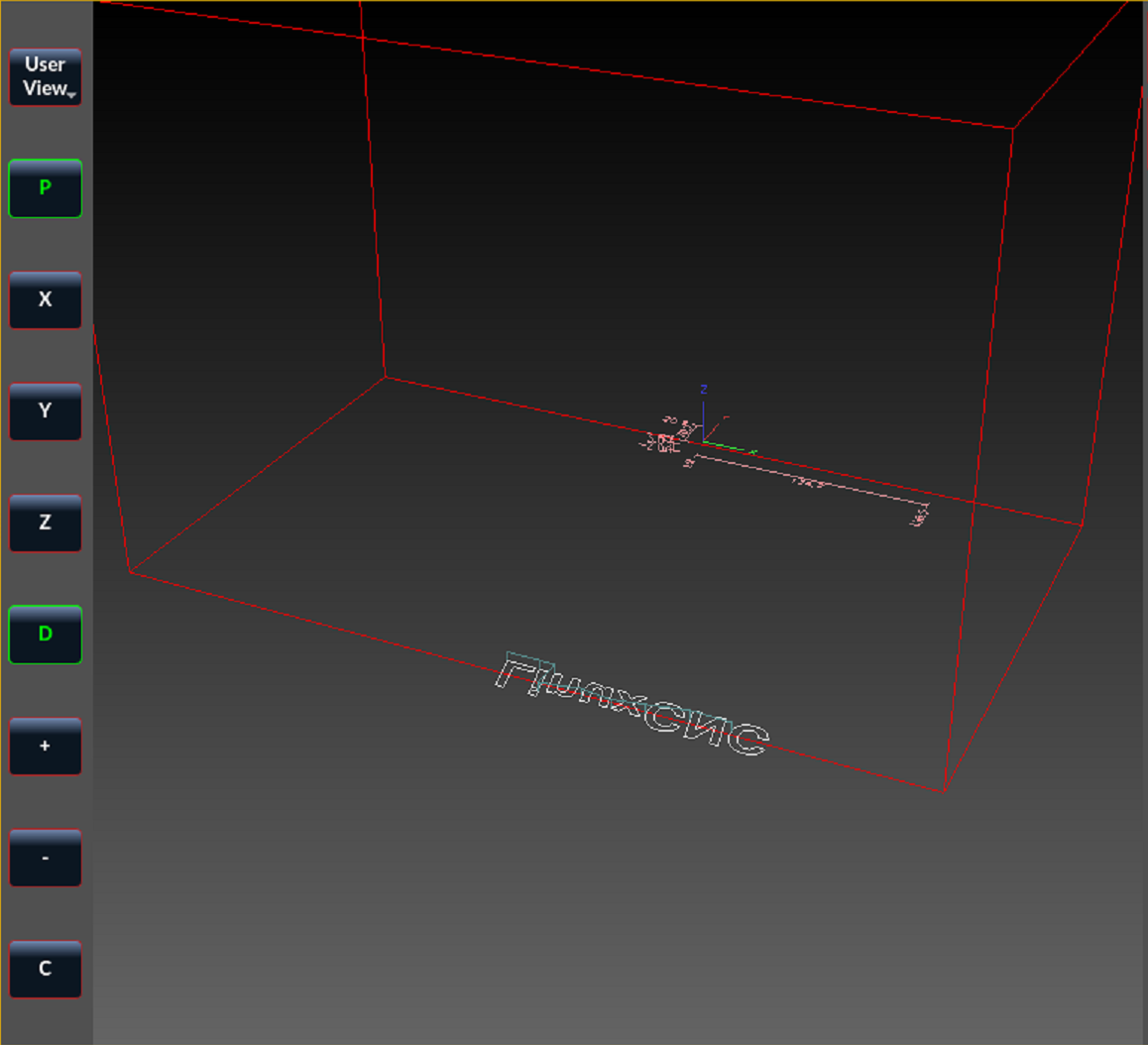

Replied by Aciera on topic Red Machine Outline is backwards in Y dimension

Red Machine Outline is backwards in Y dimension

Category: Qtvcp

- Vector

21 Feb 2025 06:30

Replied by Vector on topic Red Machine Outline is backwards in Y dimension

Red Machine Outline is backwards in Y dimension

Category: Qtvcp

- Vector

21 Feb 2025 06:29

Replied by Vector on topic Red Machine Outline is backwards in Y dimension

Red Machine Outline is backwards in Y dimension

Category: Qtvcp

- Aciera

21 Feb 2025 06:20

Replied by Aciera on topic (solved) Documentation Hobbing

(solved) Documentation Hobbing

Category: General LinuxCNC Questions

- Traken

- Traken

21 Feb 2025 06:16

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Category: Basic Configuration

- 109jb

- 109jb

21 Feb 2025 06:03

Replied by 109jb on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- 109jb

- 109jb

21 Feb 2025 05:46

Replied by 109jb on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- unknown

- unknown

21 Feb 2025 05:16

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- unknown

- unknown

21 Feb 2025 05:02

Replied by unknown on topic zramswap wont start error on boot

zramswap wont start error on boot

Category: Installing LinuxCNC

- unknown

- unknown

21 Feb 2025 05:00

Replied by unknown on topic zramswap wont start error on boot

zramswap wont start error on boot

Category: Installing LinuxCNC

- 109jb

- 109jb

21 Feb 2025 04:52 - 21 Feb 2025 04:54

Replied by 109jb on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- spina

- spina

21 Feb 2025 03:35 - 21 Feb 2025 04:34

Replied by spina on topic zramswap wont start error on boot

zramswap wont start error on boot

Category: Installing LinuxCNC

- unknown

- unknown

21 Feb 2025 03:34

Replied by unknown on topic Trouble with Linucnc RPi

Trouble with Linucnc RPi

Category: Installing LinuxCNC

- PCW

21 Feb 2025 03:29

- 109jb

- 109jb

21 Feb 2025 03:23

Replied by 109jb on topic Trouble with Linucnc RPi

Trouble with Linucnc RPi

Category: Installing LinuxCNC

Time to create page: 0.366 seconds