Search Results (Searched for: )

- Ehsan_R

- Ehsan_R

30 Dec 2024 20:45

Replied by Ehsan_R on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- 10K

30 Dec 2024 20:19 - 30 Dec 2024 20:24

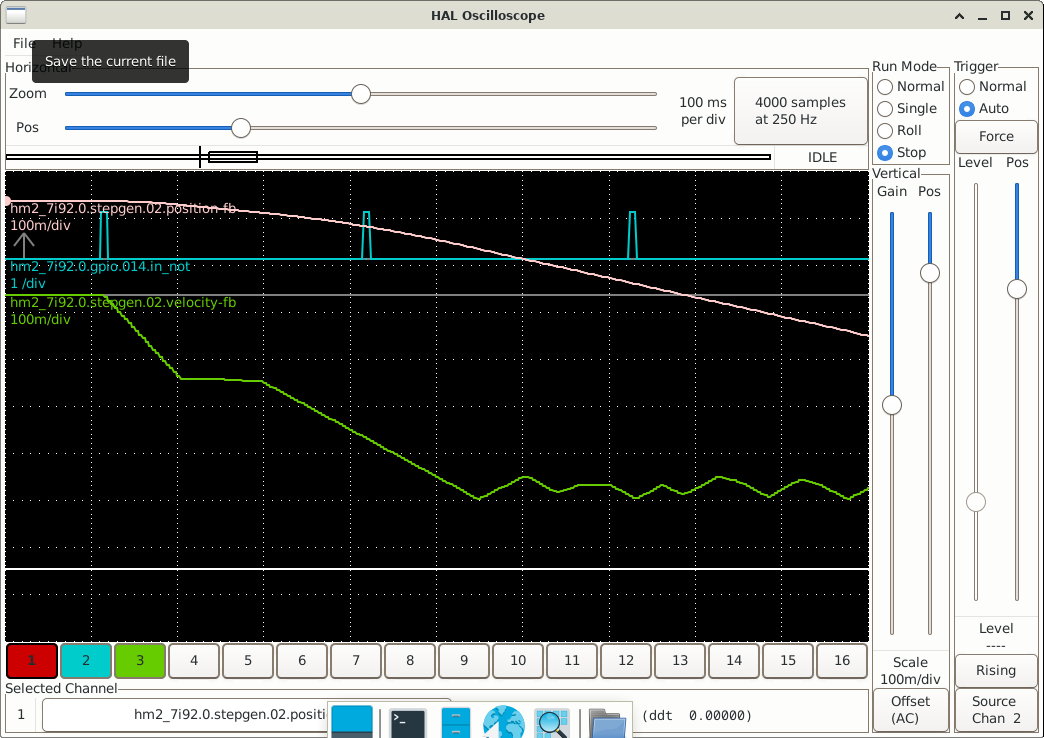

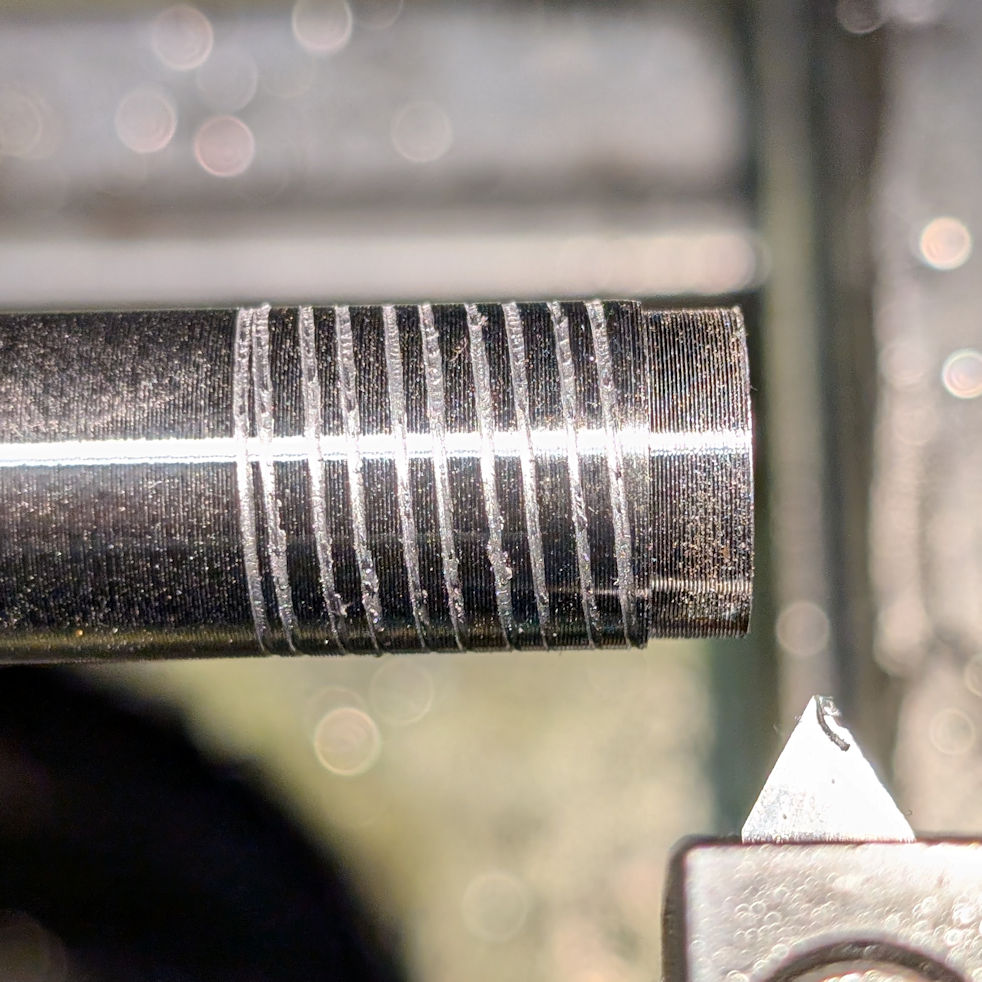

Replied by 10K on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- __Tom

- __Tom

- IronManDylan

- IronManDylan

30 Dec 2024 19:58

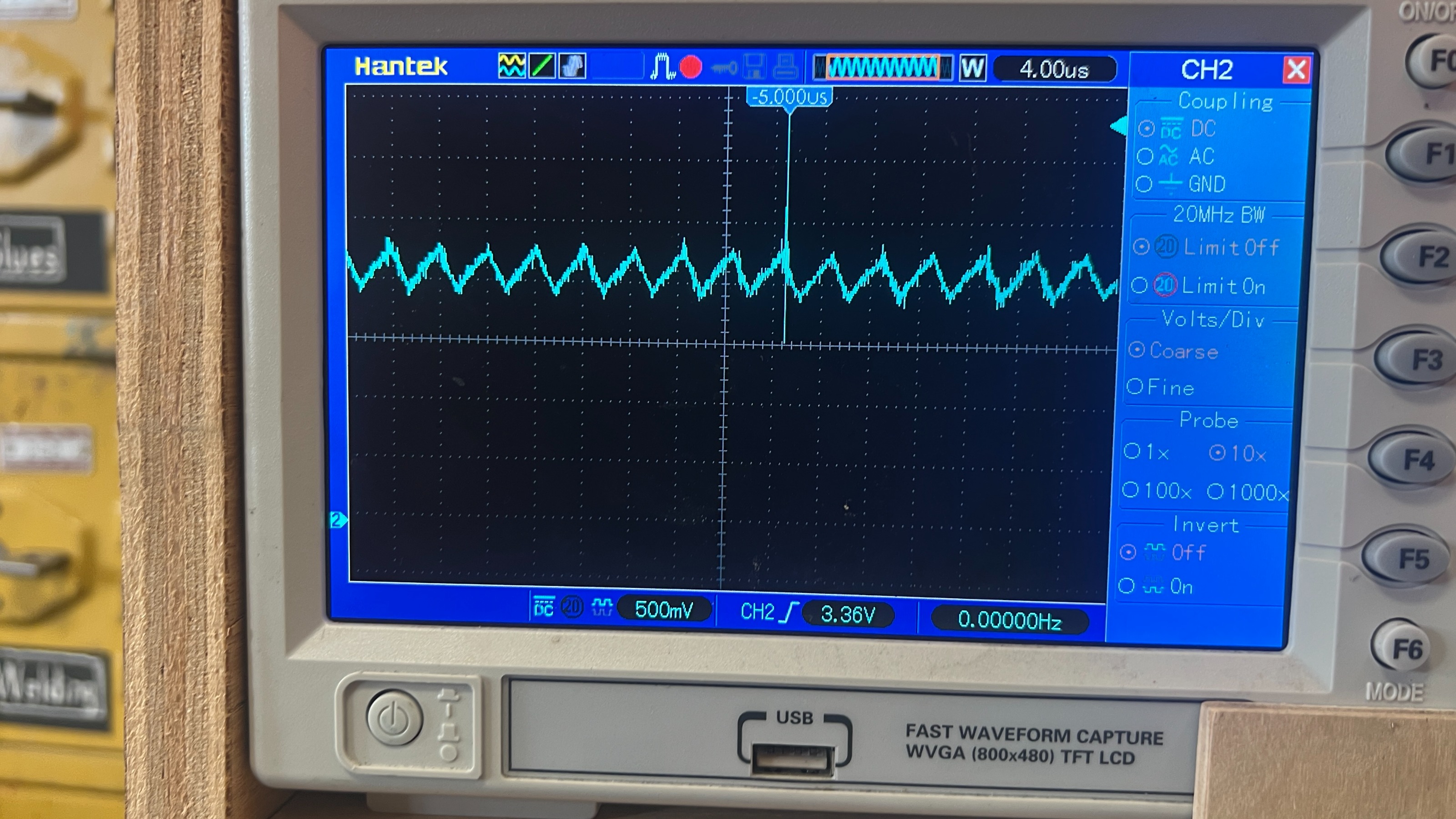

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- IronManDylan

- IronManDylan

30 Dec 2024 19:37

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- PCW

30 Dec 2024 18:17 - 30 Dec 2024 18:21

Replied by PCW on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- IronManDylan

- IronManDylan

30 Dec 2024 17:20

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- PCW

30 Dec 2024 17:05 - 30 Dec 2024 17:09

Replied by PCW on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- 10K

30 Dec 2024 15:58

Replied by 10K on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- 10K

30 Dec 2024 15:32 - 30 Dec 2024 15:36

- smc.collins

- smc.collins

30 Dec 2024 14:04

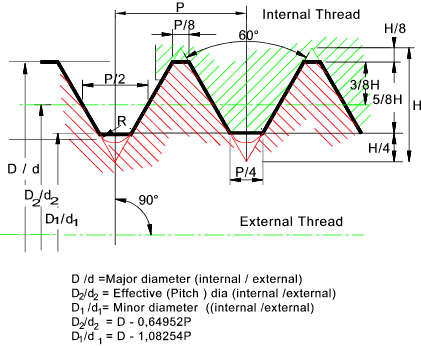

Replied by smc.collins on topic Chasing Threads and Re-Threading

Chasing Threads and Re-Threading

Category: Off Topic and Test Posts

- thomaseg

- thomaseg

30 Dec 2024 12:54

Replied by thomaseg on topic EL5112: Change PDO assignments via LinuxCNC?

EL5112: Change PDO assignments via LinuxCNC?

Category: EtherCAT

- Grew

- Grew

30 Dec 2024 12:46

Replied by Grew on topic Python4Lazarus Undefined symbol: PyExc_ValueError

Python4Lazarus Undefined symbol: PyExc_ValueError

Category: Advanced Configuration

- tommylight

30 Dec 2024 12:20

Replied by tommylight on topic MESA 7i96S STEP DIR I/O compatibility

MESA 7i96S STEP DIR I/O compatibility

Category: Driver Boards

- Hakan

- Hakan

30 Dec 2024 11:51

Replied by Hakan on topic EL5112: Change PDO assignments via LinuxCNC?

EL5112: Change PDO assignments via LinuxCNC?

Category: EtherCAT

Time to create page: 0.556 seconds