Search Results (Searched for: )

- tommylight

20 Dec 2024 02:06

Replied by tommylight on topic Some 3D printing advice to start this section

Some 3D printing advice to start this section

Category: Additive Manufacturing

- spicer

20 Dec 2024 01:24

Replied by spicer on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- mBender

- mBender

20 Dec 2024 00:54

Replied by mBender on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- PCW

20 Dec 2024 00:51

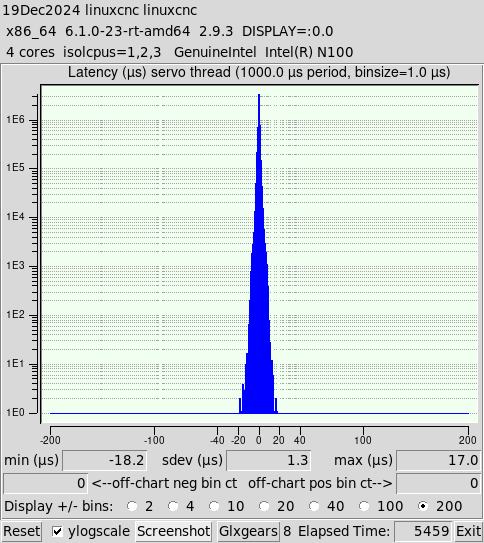

Replied by PCW on topic linuxcnc 2.9.2 (live) on the intel n100 cpu

linuxcnc 2.9.2 (live) on the intel n100 cpu

Category: Computers and Hardware

- edmarwjr

- edmarwjr

20 Dec 2024 00:47

4 thou error on a small part was created by edmarwjr

4 thou error on a small part

Category: General LinuxCNC Questions

- itsbrian

- itsbrian

19 Dec 2024 23:56

Replied by itsbrian on topic linuxcnc 2.9.2 (live) on the intel n100 cpu

linuxcnc 2.9.2 (live) on the intel n100 cpu

Category: Computers and Hardware

- my1987toyota

19 Dec 2024 23:35

Replied by my1987toyota on topic Some 3D printing advice to start this section

Some 3D printing advice to start this section

Category: Additive Manufacturing

- CNC_ANDI

- CNC_ANDI

19 Dec 2024 22:11

- Cant do this anymore bye all

19 Dec 2024 22:10

Replied by Cant do this anymore bye all on topic Raspberry Pi 5 with 7c81 WORKING!

Raspberry Pi 5 with 7c81 WORKING!

Category: Driver Boards

- MaHa

- MaHa

19 Dec 2024 20:36

Replied by MaHa on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- IronManDylan

- IronManDylan

19 Dec 2024 20:23

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

- jasont64

- jasont64

19 Dec 2024 20:06

Replied by jasont64 on topic G540 Timings (defaults too slow)

G540 Timings (defaults too slow)

Category: PnCConf Wizard

- PCW

19 Dec 2024 19:53

Replied by PCW on topic Another joint 0 on limit switch error

Another joint 0 on limit switch error

Category: Basic Configuration

- agima2

- agima2

19 Dec 2024 19:41

Replied by agima2 on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- vibram

- vibram

19 Dec 2024 19:35

Replied by vibram on topic Another joint 0 on limit switch error

Another joint 0 on limit switch error

Category: Basic Configuration

Time to create page: 0.419 seconds