Search Results (Searched for: )

- Kieran

- Kieran

22 Jul 2025 05:18 - 22 Jul 2025 05:22

- Kieran

- Kieran

22 Jul 2025 05:16

- tcbmetalworks

- tcbmetalworks

22 Jul 2025 03:46

Replied by tcbmetalworks on topic Automatic band saw marvel v10a

Automatic band saw marvel v10a

Category: CNC Machines

- mBender

- mBender

22 Jul 2025 02:18

Replied by mBender on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- rubinstu

- rubinstu

22 Jul 2025 00:56 - 22 Jul 2025 00:59

Weird G54 orientation was created by rubinstu

Weird G54 orientation

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

22 Jul 2025 00:11

- cakeslob

- cakeslob

22 Jul 2025 00:02

Replied by cakeslob on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- kn612

- kn612

21 Jul 2025 23:53

Replied by kn612 on topic Servo Driver Plasma Retrofit

Servo Driver Plasma Retrofit

Category: Plasmac

- GuiHue

21 Jul 2025 22:00

- cristachelu

- cristachelu

21 Jul 2025 20:30

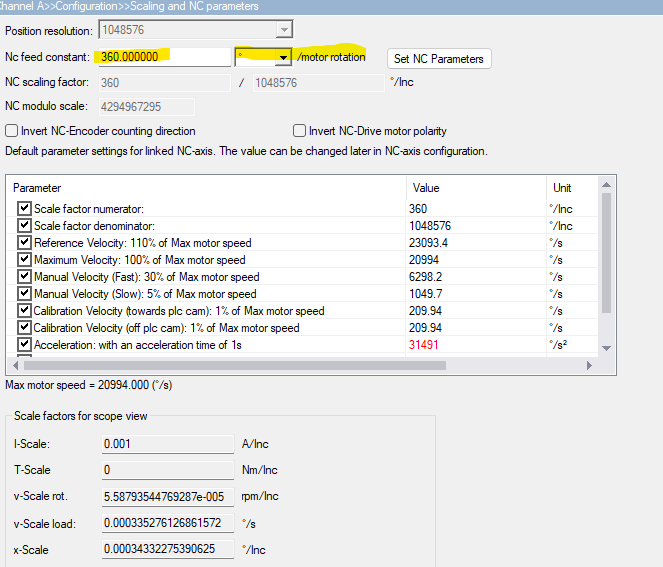

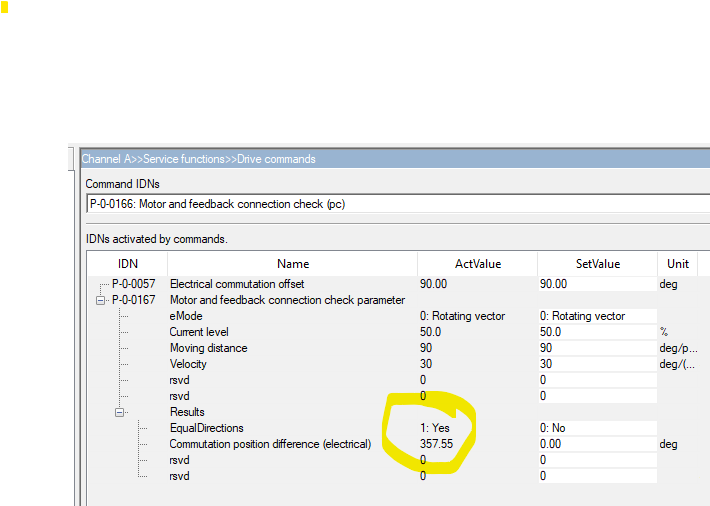

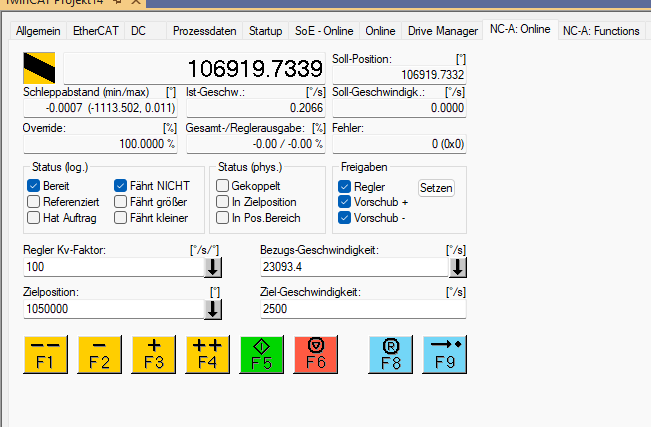

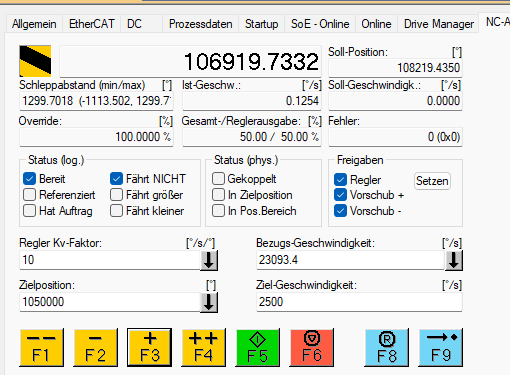

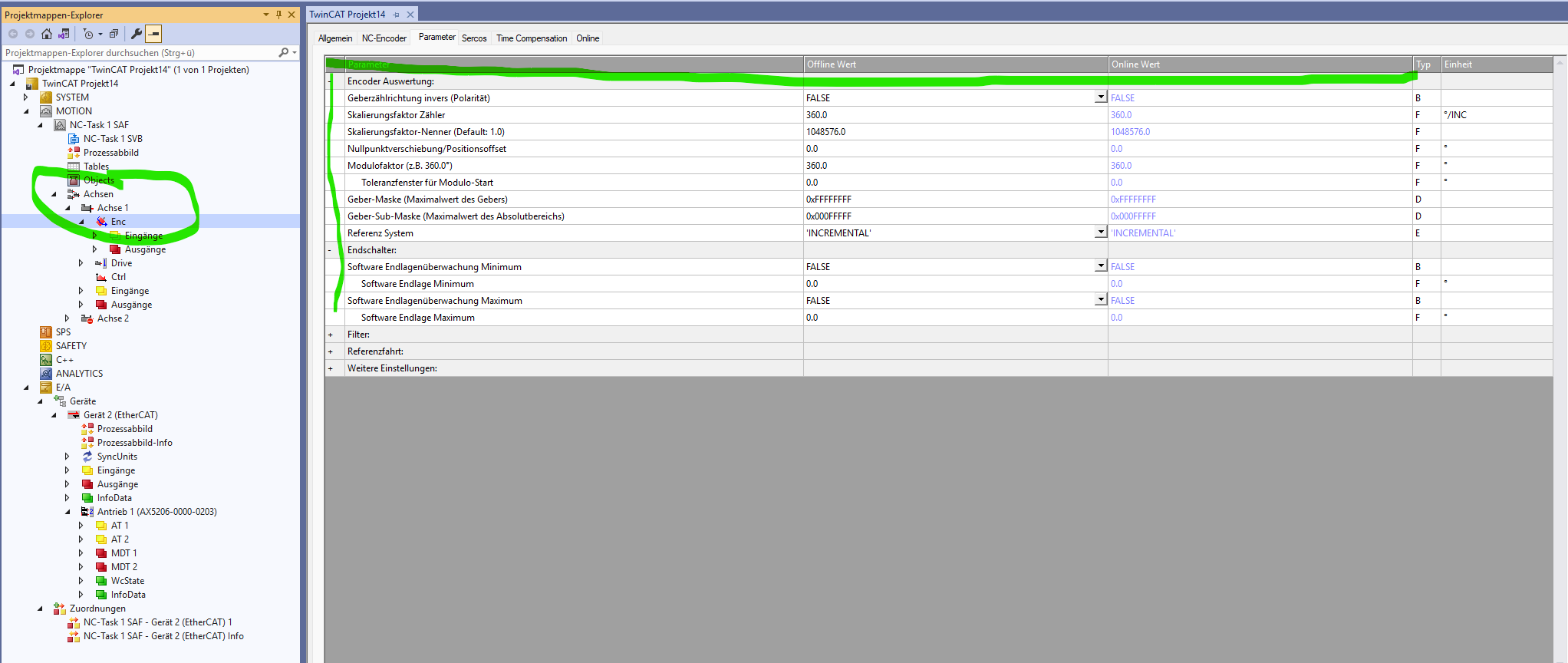

Replied by cristachelu on topic Ethercat Servo+Glas scale = clods loop

Ethercat Servo+Glas scale = clods loop

Category: EtherCAT

- PCW

21 Jul 2025 19:36

Replied by PCW on topic 7i96s Flash for additional PWM and Wiring for laser

7i96s Flash for additional PWM and Wiring for laser

Category: Driver Boards

- roland100

- roland100

21 Jul 2025 19:15

Replied by roland100 on topic 7i96s Flash for additional PWM and Wiring for laser

7i96s Flash for additional PWM and Wiring for laser

Category: Driver Boards

- Ac1dburn

- Ac1dburn

21 Jul 2025 18:50

Replied by Ac1dburn on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- PCW

21 Jul 2025 18:36

Replied by PCW on topic 7i96s Flash for additional PWM and Wiring for laser

7i96s Flash for additional PWM and Wiring for laser

Category: Driver Boards

- kn612

- kn612

21 Jul 2025 18:35

Replied by kn612 on topic Servo Driver Plasma Retrofit

Servo Driver Plasma Retrofit

Category: Plasmac

Time to create page: 0.376 seconds